Designing a factory is a critical step that determines the success of an industrial construction project. Investors preparing to build or renovate a factory often have many concerns about costs, timelines, procedures, and technical standards. BIC has compiled the 10 most common questions along with essential guidelines and notes to help investors better understand and prepare for their factory design projects.

1. How much does it cost to design a factory?

- Scale and area: The total floor area directly influences the design cost. Larger factories generally have a lower design unit rate per square meter compared to smaller ones due to economies of scale.

- Project complexity: A simple warehouse design costs less than a specialized facility that requires technical standards for example, food processing factories that must meet strict hygiene standards or electronics plants that need cleanroom environments.

- Special functional or technical requirements: If the factory includes complex production lines, integrated office areas, auxiliary zones, cleanrooms, or crane systems, the design cost will increase because more detailed calculations and drawings are required.

- Design firm’s experience and expertise: Fees also depend on the reputation and experience of the design consultant. Reputable firms may charge higher fees, but they provide optimized designs that minimize errors and construction risks.

- Urgent timeline: If the investor requires the design to be completed within a very short period, additional costs may arise from overtime or mobilizing more designers.

- Per-square-meter pricing: Design fees are often calculated based on area. For instance, the design cost for a pre-engineered steel factory typically ranges from 1 – 1.6 USD/m² (equivalent to about 24,000 – 38,000 VND/m²), depending on the project’s scale and requirements. Therefore, a 5,000 m² factory may have an estimated design cost of 75 – 150 million VND.

- Typical market rates: Some firms quote rates between 10,000 – 50,000 VND/m², with lower unit prices for larger projects. For example, designing a 3,000 m² factory may cost around 60 – 90 million VND.

- As a percentage of total investment: Design fees usually account for 2–5% of the total factory construction cost. Although a small portion of the budget, design is a crucial phase that ensures the entire project is well-prepared and cost-efficient.

- Optimized design saves construction costs: A well-executed design optimizes the structure, materials, and functionality, thereby reducing both construction and long-term operating expenses. For example, a well-engineered structure can save hundreds of millions of VND in steel and concrete.

- Avoiding costly errors: Investing in comprehensive, detailed design documentation at the start helps prevent technical errors or on-site modifications during construction, which could lead to unnecessary expenses. Clear drawings also enable contractors to build accurately and efficiently.

- Budget control: Through the design process, investors can estimate material quantities, equipment specifications, and total project costs. Therefore, design fees should be viewed as a strategic investment for effective cost management throughout the project.

- Average time: Normally, the factory design time lasts about 15 to 45 working days, depending on the scale and complexity of the project. Small workshops with simple requirements can be completed within 2–3 weeks, while large projects may take 1–2 months for the design phase.

- Design stages: The design process is usually divided into several stages: site survey, preliminary design, detailed technical design, and adjustment/supplement based on feedback. Each stage takes a certain amount of time (for example: preliminary design 1–2 weeks, technical design 2–4 weeks).

- Practical example: An architectural design company said that the design time for a medium-sized factory (~2000–3000m²) usually takes 15–20 days for a complete set of design documents. For larger factories or special requirements, the time can take up to 30–40 days.

- Average construction time: The construction of the factory usually takes much longer than the design. Depending on the scale, the construction time can range from several months to more than a year. For example, a 1,000m² pre-engineered factory can be built in 2–3 months, while a 10,000m² manufacturing plant may need 6–12 months of construction.

- Construction stages: Construction includes the following steps: foundation (1–2 months depending on soil conditions), erection of the structural frame, enclosure (walls, roof), finishing and installation of technical systems. Each step can be partly carried out in parallel to shorten the schedule.

- Permitting and preparation: Note that before construction there is still time for building permit application, fire protection approval, etc., which can take an additional 1–2 months. Therefore, the total time from the start of design to factory handover can range from 6 months to more than 1 year depending on scale.

- Scale and complexity: The larger the factory, the longer the design and construction take. If the design requires specific technical features (e.g. cleanroom, deep-cooling system, etc.), more time is needed to ensure accuracy in detail.

- Legal procedures: The schedule may be delayed if the construction permit or fire protection approval process is prolonged. Investors should prepare documents early and work closely with authorities to avoid delays.

- Construction conditions: An open construction site and favorable weather help accelerate the progress. Conversely, if the site is narrow, construction is during the rainy season, or there are site clearance issues, the time will be extended.

- Contractor capability: A professional design and construction contractor will manage time more effectively. They can plan detailed schedules, mobilize manpower and equipment reasonably to ensure on-time completion.

When designing a factory, the investor and architect need to pay attention to many factors to ensure the factory operates efficiently, safely, and in compliance with regulations. Below are important considerations:

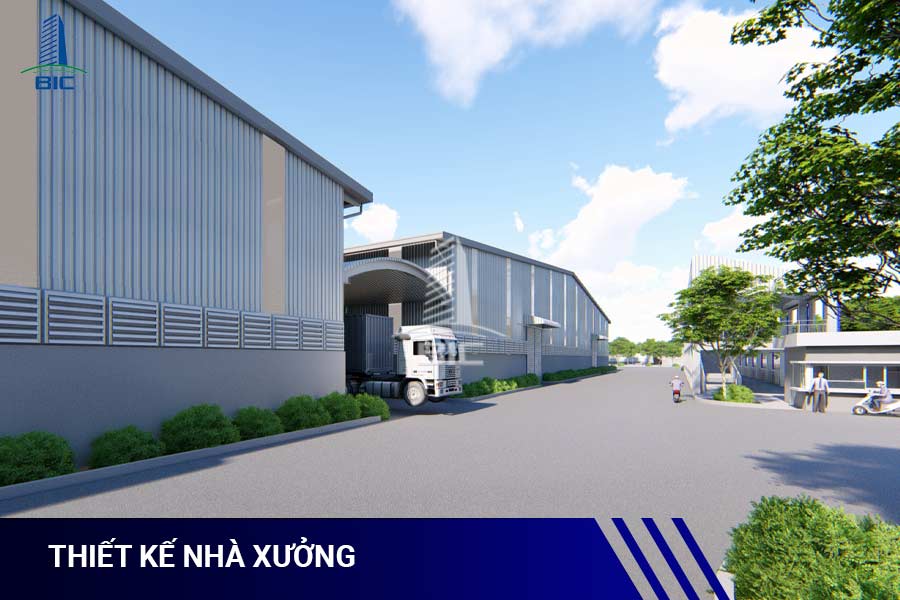

- Suitable for production function: The design must be based on the production process and specific type of industry. The layout should be reasonable for production lines, warehouses, import-export areas. For example, a food processing factory needs separate areas for raw materials and finished products to avoid cross-contamination.

- Rational layout and space arrangement: It is necessary to optimize the factory layout to make the most of space. Internal walkways, machinery locations, office areas, and canteens should be scientifically arranged for easy operation. At the same time, utilize factory height to install storage racks or mezzanine floors if needed to increase usable area.

- Safe load-bearing structure: Choose a structural solution (pre-engineered steel frame or reinforced concrete) suitable for span and load. The structure must ensure stability, withstand machinery load, goods, and environmental impacts (wind, storm, earthquake if any). This is the key factor ensuring construction safety.

- Technical systems (M&E): Synchronously design the electrical, water, ventilation, air conditioning, fire protection (FPP) systems from the beginning. Ensure the factory has sufficient lighting, natural or forced ventilation, and cooling systems if needed to create a comfortable and safe working environment for workers.

- Occupational safety and fire prevention: The factory must meet requirements for emergency exits and fire protection equipment (extinguishers, sprinklers, alarms) according to standards. Construction materials should be fire-resistant and non-slip (for floors). In addition, the design should consider evacuation plans and assembly points in case of incidents.

- Environmental factors: Pay attention to waste treatment, industrial wastewater systems, noise and dust control if the factory generates these elements. For example, a dyeing workshop must have a standard wastewater treatment system before discharge into the environment. Ventilated design and surrounding greenery also help reduce noise, dust and create a fresher working environment.

- Energy and operating cost optimization: The design should utilize natural light and ventilation to reduce lighting and cooling electricity costs. Install skylights, translucent roof sheets, or light wells if possible. Also consider roof and wall insulation to make the factory cooler and save air-conditioning electricity.

- Compliance with codes and standards: Ensure the design complies with national and local technical standards for factory construction (foundation, structure, load, fire protection, environment, etc.). (See more details on standards in section 5 below.)

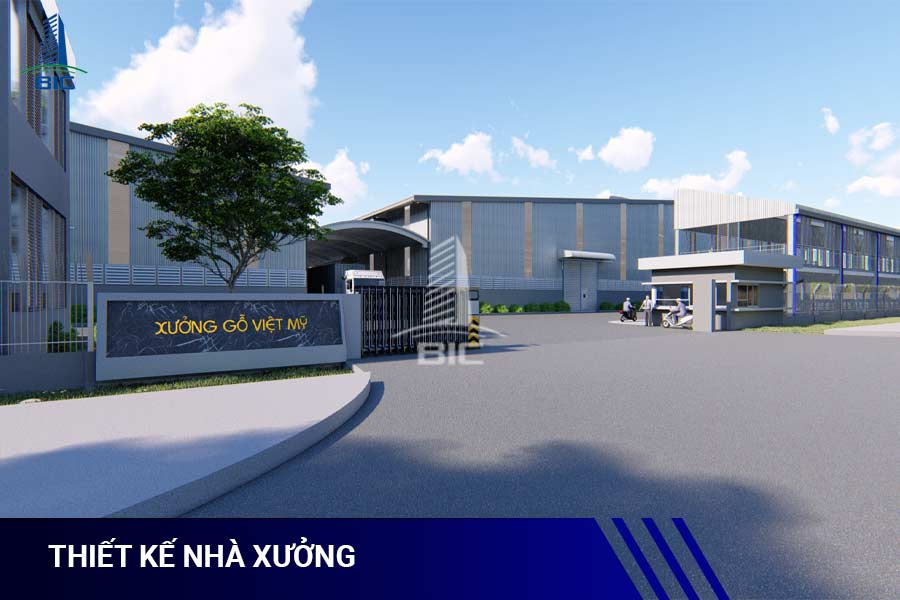

- Aesthetics and branding: Although it is an industrial factory, aesthetics should also be considered. Designing a beautiful façade, gate, and office area harmonizing with the landscape will create a good impression on partners and customers when visiting and show the professionalism of the enterprise.

(Note: Each industry may have its own requirements when designing factories, so investors should discuss specific needs carefully with the design unit.)

A professional factory design process usually goes through the following basic steps. Understanding the process helps investors coordinate effectively with the design unit and track progress more easily:

- Survey the construction land: Engineers will survey the site (or existing factory if renovated) to understand the area, terrain, geology, direction, infrastructure connections (electricity, water, transportation, etc.). This is the basis for proposing a suitable design solution.

- Collect requirements from the investor: The architect discusses with the investor about usage needs: production type, capacity, number of machines, workers, warehouse and office needs, as well as expected investment budget. At the same time, learn about special requirements (e.g. need a 10-ton crane, need an ISO 8 cleanroom, etc.).

- Planning and legal analysis: At this stage, the design unit also checks related construction planning, allowable construction density, height limit, and legal regulations applied to the site (such as road boundaries, safety corridors, etc.) to ensure compliance from the beginning.

- Preliminary functional layout: The architect proposes several layout plans for the factory based on the collected information. This plan outlines the arrangement of production areas, warehouses, offices, technical and auxiliary areas on the site. The goal is to ensure logical production flow and reasonable material–product movement.

- Exterior architectural sketch: Along with the layout, the architect may sketch the factory appearance (roof structure, skylights, windows, colors, wall materials, surrounding landscape, etc.). This helps the investor visualize the future building and provide feedback.

- Discussion and plan approval: The preliminary plan is presented for the investor’s review. Then both parties discuss and may adjust some details for better suitability. When the investor agrees on the layout and preliminary architecture, the project moves to detailed design.

- Detailed architectural design: Includes detailed drawings of floor plans, elevations, cross-sections, and details of the roof, walls, doors, gates, etc. At this stage, architects also arrange detailed rooms (if there are offices, canteens, restrooms, etc.) for convenient use.

- Structural design: Structural engineers calculate and show on drawings the load-bearing elements: foundations, columns, beams, trusses, purlins, bracing, etc., ensuring sufficient load capacity. For factories, structures are usually optimized for wide column spans to reduce obstruction for production space.

- M&E system design: Includes electrical, lighting, water supply and drainage, ventilation, air conditioning, fire protection, security camera, and internet systems. These systems are coordinated with architecture and structure (e.g. cable and pipe layouts avoid conflicts with beams and columns). Especially, the fire protection system must be designed according to regulations (sprinkler head density, fire extinguisher locations, emergency exits, etc.).

- Coordination and cross-checking: During detailed design, architects and engineers continuously coordinate to ensure all parts fit together. The completed drawings are reviewed to ensure no conflicts (e.g. doors not blocked by beams, pipes not cutting through load-bearing beams unless with sleeves).

- Investor approval: When technical design drawings are completed, the investor reviews the entire set. If any details are unreasonable or not as desired, this is the time to request adjustments before closing the file.

- Design appraisal (if required): For large projects or by law, design documents may need to be appraised by an independent unit to check safety and standard compliance. Appraisal helps detect early errors (if any) and confirm design quality.

- Government approval: The investor submits the factory design drawings to apply for a construction permit. The construction authority will review and approve if the documents meet requirements. Similarly, the fire protection design must be approved by the Fire Department before construction. This stage depends on state procedures, usually from several weeks to 1–2 months.

- Design document handover: The factory design consultant hands over the complete drawing set, including architecture, structure, electrical, plumbing, and fire protection to the investor. This serves as a basis for bidding and construction implementation. Complete drawings also help estimate costs accurately.

- Author supervision: During construction, the design unit often sends representatives for author supervision, ensuring the building is constructed according to the design. If minor field adjustments arise, architects will advise promptly to ensure both technical quality and design intent.

- Completion and acceptance: After construction, the design unit may assist in inspecting the project compared with drawings, participating in acceptance of items. The as-built dossier (as-built drawings) will be prepared for registration and future use.

(Note: Some projects may combine or adjust stages to suit actual conditions, but the main steps remain as above. Investors should choose a professional design unit to ensure a smooth process.)

Factory design must comply with many standards and regulations to ensure safety, quality, and legality for the project. Below are the important standards and regulations that investors need to note:

- Foundation and structural standards: Ensure that the foundation design can withstand the load of machinery and goods and is suitable for the soil conditions (refer to TCVN standards on foundation design for buildings). The factory structure must comply with standards on wind, storm, and earthquake loads (for example: TCVN 2737 on loads and impacts, relevant standards for steel and concrete structure design...).

- Roof and skylight standards: Factories often have large spans, so the roof slope and truss structure must follow standards to ensure good rainwater drainage and wind load resistance. For example: the roof slope for corrugated iron roofs is usually 10-15% to allow fast water drainage. The skylight and window systems should also comply with natural lighting standards for industrial buildings.

- Floor and ground load standards: Factory floors must be calculated to withstand the load of machinery, forklifts, and goods. Normally, the ground load for light industrial factories is about 2–3 tons/m², while heavy factories may require 5–10 tons/m² (depending on specific equipment). Industrial floor standards also regulate the flatness of the floor to ensure forklifts move safely.

- Lighting and ventilation levels: Comply with lighting standards for factories (minimum illumination at work areas, usually around 200–300 lux depending on the type of work). Factory ventilation must also meet air change standards per hour, ensuring air circulation and avoiding stagnation, especially in factories with heat or dust generation.

- Noise and vibration standards: If the factory generates noise or vibration (e.g., mechanical workshops), the design must consider soundproofing and noise reduction so that levels do not exceed environmental and labor standards. There are regulations on maximum noise levels in production areas and surrounding residential zones that enterprises must comply with.

- Fire protection standards: Factories must strictly comply with fire protection regulations. Specifically: install automatic fire alarm systems, firefighting systems (fire extinguishers, fire hydrants, or automatic sprinklers depending on the scale of the factory) in accordance with Regulation QCVN 06:2022/BXD and related fire protection standards. Arrange emergency exits, Exit signs, and evacuation direction boards properly. The fire protection design dossier must be appraised by the authorities before construction.

- Environmental protection regulations: If the factory discharges wastewater, exhaust gas, or solid waste, it must design treatment systems that meet environmental standards (such as QCVN for industrial wastewater, industrial emissions...). For example: a dyeing factory must have a wastewater treatment system meeting the standards before discharge into receiving sources. At the same time, the investor must prepare an Environmental Impact Assessment (EIA) or Environmental Protection Plan and obtain approval before construction.

- Occupational safety and health: Factory design must comply with labor safety regulations, such as ensuring ventilation, lighting, and working temperature within permissible limits; having measures to minimize harmful factors (dust, chemicals, noise). Arrange toilets, changing rooms, and rest rooms for workers according to regulations of the Ministry of Construction and the Ministry of Health for industrial works.

- Disaster prevention standards: Depending on the geographical area, factories need to be designed to meet storm, flood, and earthquake resistance requirements. For example, in Vietnam, roofs and doors must withstand level-12 storms in storm-prone areas, or the factory floor elevation must be higher than the highest recorded flood level to prevent inundation.

Construction permit: Before starting construction, the investor must apply for a construction permit for the factory (except for cases exempted by law, but most projects still require it). The application dossier includes basic design drawings, land use right documents, fire protection appraisal, EIA, etc. The design must comply with planning indicators (construction density, height, setback) to be granted a permit.

Fire protection appraisal: As mentioned, the fire protection design dossier must be appraised and certified by the Fire Prevention Police Department before construction. After construction, the factory must also pass fire protection acceptance testing before operation.

Other permits: Depending on the project’s nature, additional approvals may be required: security and order certificate (for specific industries), wastewater discharge permit (if discharging wastewater), electrical and water connection permits, etc. These permits require that the design clearly show the relevant items for authorities to review.

(Note: Investors should work with design units and authorities early to clearly understand all standards and procedures to comply with. Failure to meet standards or missing permits may lead to construction suspension or rejection of acceptance for use.)

Optimizing factory design and construction costs does not mean choosing the cheapest option, but spending efficiently and avoiding waste. Below are solutions to help investors optimize costs while ensuring design quality:

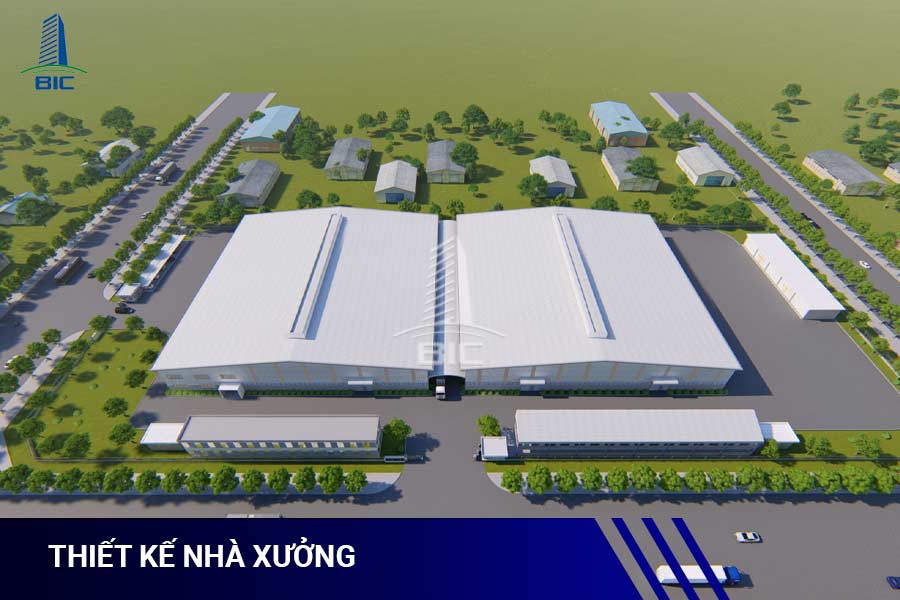

- Choose the design plan that suits your needs: From the start, clearly define your functional needs and actual scale. Design for the right purpose, avoiding wasted space or unnecessary construction. For example, if you currently only need a 5,000m² factory, don’t design 8,000m² which causes unnecessary construction and design costs. However, you can design foundations and frames ready for future expansion (if you plan to expand later).

- Simple design and space optimization: A square layout with a simple structure (fewer divided spaces) will be more cost-effective than a complex one. Utilize height for mezzanines or high shelves instead of adding new floor area. Multi-story factory design may be a solution if land is limited, but note that structural costs will be higher than a one-story factory. Balance land-use efficiency and cost.

- Choose economical structures and materials: For factories, there are usually two main options: pre-engineered steel or reinforced concrete. Pre-engineered steel frames are often cheaper and faster to build for large-span factories. Compare structural options to choose the most cost-efficient one. Building materials (such as roofing sheets, wall panels, and flooring) also vary in cost choose durable, reasonably priced materials, avoiding unnecessary luxury materials for production functions.

- Take advantage of natural light and ventilation: Designing skylights, translucent roofing, and high ventilation windows may slightly increase initial design/construction costs, but will reduce long-term operating costs (lighting and ventilation electricity). This design investment brings long-term economic benefits and indirectly optimizes total costs.

- Hire a design-and-build contractor: Many design-and-build contractors offer reduced or free design costs if they are selected for construction. Investors can consider this option to save on design fees. However, choose reputable contractors to ensure quality.

- Compare quotations and design experience: Get quotations from several design firms to compare. However, don’t choose solely based on the lowest price and ignore quality. Review their completed projects, experience in factory design, and feedback from past clients. A good design from the start may cost a bit more but saves significantly during construction.

- Reduce changes during the design process: Each major change after finalizing the design incurs extra costs (and time). Therefore, at the early stage, the investor should clearly agree on requirements and plans with the architect. Review preliminary plans carefully together to minimize redesigns that cause cost overruns.

- Reuse or repeat existing designs: If the enterprise already has similar factories, it can reuse part of the old design (adjusting to fit the new project) instead of designing from scratch. This applies when building multiple factories with similar structures and functions (e.g., modular factories in an industrial park).

- Establish a clear financial plan: Finally, cost optimization requires planning. The investor should work with the design consultant to prepare a construction cost estimate as soon as the preliminary design is ready. From there, identify the most expensive items and look for optimization options (for example, if foundation costs are high due to weak soil, adjust the foundation solution or soil improvement method to fit the budget). This helps avoid over-budget designs that later require costly revisions.

Factory design trends change over time to improve efficiency and meet new requirements for production and environment. Below are outstanding factory design trends today (2025–2026):

- Use of renewable energy: More factories are installing solar panel systems on roofs to supply their own electricity, reducing costs and dependence on the power grid. Some also integrate wind turbines (in windy areas) to make full use of natural energy sources.

- Energy-efficient design: Prioritize natural ventilation and lighting. Use thermal insulation materials for roofs and walls (insulated roofing sheets, thermal paints) to reduce heat. Install intelligent LED lighting systems that adjust brightness based on demand and time of day. This reduces power consumption and moves toward green industrial standards.

- Environmental treatment and protection: The “eco-factory” design trend focuses on wastewater treatment and water reuse systems if possible. Arrange green spaces around the factory (partly to meet mandatory green area ratios, e.g., 20% of the factory site, partly to create landscape and reduce pollution). Green factories also use eco-friendly materials such as recycled materials, plantation timber, and non-toxic paints.

- Automated production: Modern factory designs often integrate infrastructure for automation lines, robots, and conveyors. The layout of machinery is calculated for robots or AGVs (Automated Guided Vehicles) to move smoothly. Floors and aisles must be flat and wide enough for safe operation.

- Smart management systems (IoT): The Smart Factory trend requires strong IT infrastructure: internal internet networks, IoT sensors everywhere (for temperature, humidity, machine monitoring). The design must plan space for server rooms and control centers. Arrange safe, anti-interference underground cable systems in production areas. Smart factories allow real-time production monitoring, predictive maintenance, and optimized operations.

- Smart warehouses: Many factories integrate smart warehouse systems with automated warehouse management. Warehouses are designed tall, using multi-tier smart shelves and picking robots. Floors must be highly load-bearing and extremely flat for automated forklifts to operate. This trend optimizes warehouse space and speeds up logistics.

- Energy and environment monitoring: Modern factories install BMS (Building Management Systems) to manage energy, air conditioning, and lighting efficiently. The design needs space for control cabinets and wall/ceiling sensors. This system automatically adjusts ventilation, lighting, detects gas leaks, and provides early warnings for equipment issues.

- Modular structures: The trend of modular factory design means designing structural frames and column grids in standard modules (e.g., each span 6m or 10m) for easy future expansion. Investors can first build a few modules and later add more without major impact on the existing part.

- Multi-functional spaces: The design emphasizes flexibility, allowing factories to switch functions or rearrange equipment easily. For example, use movable partitions instead of fixed walls to expand or reduce production areas when needed. Factory floors are usually made completely flat without too many fixed pits, allowing easy future layout changes.

- Load and space allowance: Engineers often design foundations and frames with extra load capacity for future installation of heavier machines or cranes. Factory roofs can also be designed to support the weight of future solar panels. This flexibility ensures the factory does not become “obsolete” quickly and can adapt to new needs.

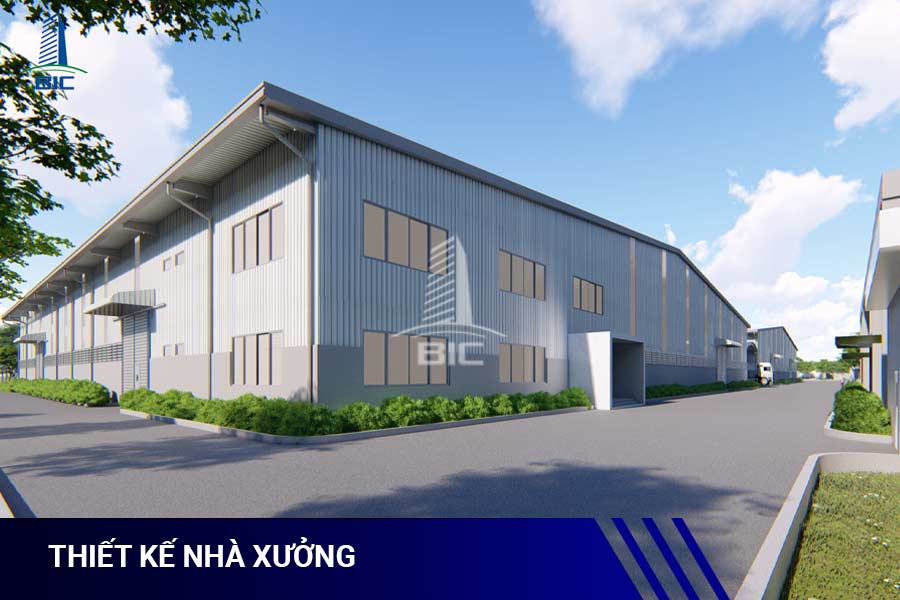

- Pre-engineered steel structures: Still the main trend thanks to economy and speed. However, modern pre-engineered structures feature larger spans, higher-strength yet lighter steel materials, reducing overall weight and cost.

- Light and durable materials: Many factories now use insulated sandwich panels (PU, EPS) for walls and roofs instead of brick walls or traditional corrugated iron. Advantages include lightweight, good insulation, quick installation, and high aesthetics. Windows and doors use modern aluminum-glass materials for better lighting and durability (tempered glass, thermally broken aluminum frames...). These materials make buildings modern and reduce maintenance costs.

- Polished concrete floors: Instead of tiled or epoxy-painted floors, some factories now pour and polish concrete floors. This method provides flat, shiny, wear-resistant surfaces with low maintenance and competitive initial cost compared to multilayer industrial floor coatings.

- New construction technologies: Prefabricated construction methods are also popular, for example, assembling steel frames and pre-cast wall panels to shorten construction time. There are also technologies like prestressed concrete for long structural members (beams, floors) and 3D-printed concrete for specific components all aiming for faster construction, reduced on-site labor, and better quality control.

(Trends such as space optimization, automation, advanced materials, and eco-friendly design are increasingly popular in 2024. Businesses should update and apply these trends appropriately for their projects.)

Investors who own old factories often face two options: renovating and expanding the existing facility or constructing a completely new one. This decision depends on several factors.

- Structure is still good: If the main structural system (foundation, columns, beams, roof) of the old factory remains in good condition and can handle the new load requirements, renovation will be more cost-effective than rebuilding. For example, a 15-year-old reinforced concrete factory that is still solid and shows no major deterioration can be reused.

- Expansion needs are not too large: When the business only needs to expand a small section or rearrange the internal layout without significantly increasing the scale, renovation is a reasonable choice. In this case, it is possible to add an extension or upgrade the floor, roof, walls, electrical and plumbing systems to suit the new function.

- Save cost and time: Renovation is usually 20–30% cheaper than new construction (depending on the level of renovation), and the construction time is shorter since the existing structure is reused. In addition, legal procedures for renovation can be simpler (in some cases, no permit is required if there are no changes to the load-bearing structure or the overall appearance).

Example: An investor has a 2,000 m² factory and wants to expand it by 1,000 m², replace the roofing sheets, and upgrade the floor for higher load capacity. Instead of demolishing and rebuilding everything, they can renovate, reinforce columns and foundations if necessary, add a new 1,000 m² steel frame, and improve the existing floor and roof. This solution costs less and construction can be completed in 2–3 months.

- Severely deteriorated structure: If the factory is too old (e.g., 30–40 years), with damaged structures and safety issues, renovation could be costly yet still ineffective. In this case, demolition and new construction are safer and more efficient in the long term.

- Major functional change: If the business shifts to a new type of production with completely different requirements (for example, converting a warehouse into a food processing plant that needs cleanrooms and specialized layouts), the old factory may not be suitable even after renovation. Building a new facility allows for optimal design from the start.

- Large-scale expansion: When production needs to double or triple, building a new factory, either on a new site or after demolishing the old one is usually more practical. Overly extensive renovation can result in a patchy, inefficient structure and long production interruptions.

- Long-term economic efficiency: Although new construction may require higher initial investment, it often results in better operational performance. For example, a new factory can be designed for energy efficiency, optimized workflow, and lower internal logistics costs. If the long-term benefits outweigh the upfront expenses, building new is the smarter choice.

Example: An old 3,000 m² pre-engineered steel factory has rusted frames and weak floors that flood during rain. The investor plans to convert it into a food processing plant, which requires strict hygiene and environmental standards. In this case, building a new factory with higher foundations, new structural materials, and food safety compliance is more reasonable than attempting to renovate the old one (which would still be unsafe and prone to incidents).

- Cost: Renovation is cheaper initially, but major renovations may approach the cost of new construction while being less durable. New construction costs more but delivers a completely new, low-maintenance building for many years.

- Time and production interruption: Renovation can often be done in stages (zoned construction), allowing production to continue partially. However, new construction typically requires halting operations or temporarily relocating, but once completed, production capacity can increase immediately.

- Legal procedures: New construction requires a full permitting process like a new project, while renovation (within certain limits) may only need notification or a minor repair permit, which is simpler.

- Asset value: A new factory enhances property value and corporate image more effectively. If the goal is to attract clients, partners, or tenants, a new, well-built factory will always be more appealing than a patchy renovated one.

- Optimal decision: The investor should assess the existing facility (with professional inspection if needed) and compare the cost–benefit of both options. In many cases, a hybrid solution renovating part of the factory and building new sections is most efficient (e.g., keeping the main frame, replacing the roof, and adding a new extension).

(In summary, if the old factory is still in good condition and only needs minor upgrades, renovation will save costs. But if production requirements change significantly or the old facility is unsafe, new construction will be more effective in the long term.)

Short answer: Yes, you should hire a professional factory design company.

Here are the reasons and advantages compared to designing it yourself or using an inexperienced team:

- Ensure quality and safety: Professional firms have experienced architects and structural, electrical, and plumbing engineers who can propose safe, optimized solutions. They accurately calculate loads, select suitable structural options, and ensure compliance with technical standards. This is crucial because factories handle heavy loads—design errors can lead to severe consequences such as roof collapse, cracked floors, or damaged machinery.

- Compliance with legal regulations: A professional firm understands the full legal process and prepares all drawings and documentation required for construction permits, fire protection approval, and environmental assessment. This helps the investor avoid paperwork delays or file rejections due to noncompliance.

- Optimize functionality and costs: Skilled architects design efficient layouts and logical workflows, ensuring smooth production operations. Experienced engineers also optimize material usage, neither overdesigning (causing waste) nor underdesigning (risking safety). A well-optimized design can save 5–10% of construction costs by avoiding material waste and design errors.

- Save time: Professional firms work with clear schedules and complete designs on time. In contrast, doing it yourself or using unqualified personnel can lead to repeated revisions and long delays. Time is money having the design ready early means the project can start and operate sooner.

- Creative and flexible ideas: Experienced designers have a library of ideas and practical solutions. They can suggest options the investo