Effective small factory design is a key factor in optimizing production processes, ensuring worker safety, and reducing costs. For factories with limited space, the efficient arrangement of the workspace becomes even more critical. Businesses often face challenges in balancing space utilization and compliance with safety regulations. These challenges demand meticulous attention in selecting materials, layout planning, and designing technical systems. In this article, BIC will share essential tips to help optimize space and functionality for small factories, enabling businesses to maximize every square meter.

Rational small factory design is crucial for ensuring smooth production operations, cost savings, and compliance with legal regulations. First, cost savings is the most obvious benefit. By optimizing space, businesses can reduce unnecessary construction areas, thereby cutting initial construction costs. Moreover, using appropriate materials and smartly designed technical systems can help save energy, reducing operational costs over time.

Beyond cost considerations, a well-designed small factory also contributes to improved production efficiency. Organizing the space scientifically, from machinery placement to clearly defined functional zones, ensures a smooth workflow, minimizing time and energy waste. This allows businesses to increase productivity and improve product quality.

Ensuring worker safety is also a critical aspect when designing a small factory. A well-thought-out design can eliminate potential hazards, such as cramped areas, poor lighting, or inadequate ventilation. This creates a safe and comfortable working environment, reducing the risk of workplace accidents and protecting employee health.

Finally, complying with legal requirements is something every business must keep in mind when designing and building a small factory. Even with limited space, small factories must still adhere to regulations regarding construction, fire safety, and labor safety. Proper design not only helps businesses avoid legal issues but also safeguards their reputation and ensures sustainable business operations in the future.

When designing a small factory, detailed planning is crucial for project success.

- Determining the factory's purpose is the first step, as the intended use directly impacts space layout and material selection. For example, a factory for production will require space for machinery, production areas, and raw material storage, while a warehouse will need spacious, easily accessible storage areas.

- Analyzing the production process helps identify the most efficient locations for machinery and equipment. The production process involves the movement of materials, products, and workers, so a well-thought-out layout will minimize movement time and effort, increasing productivity.

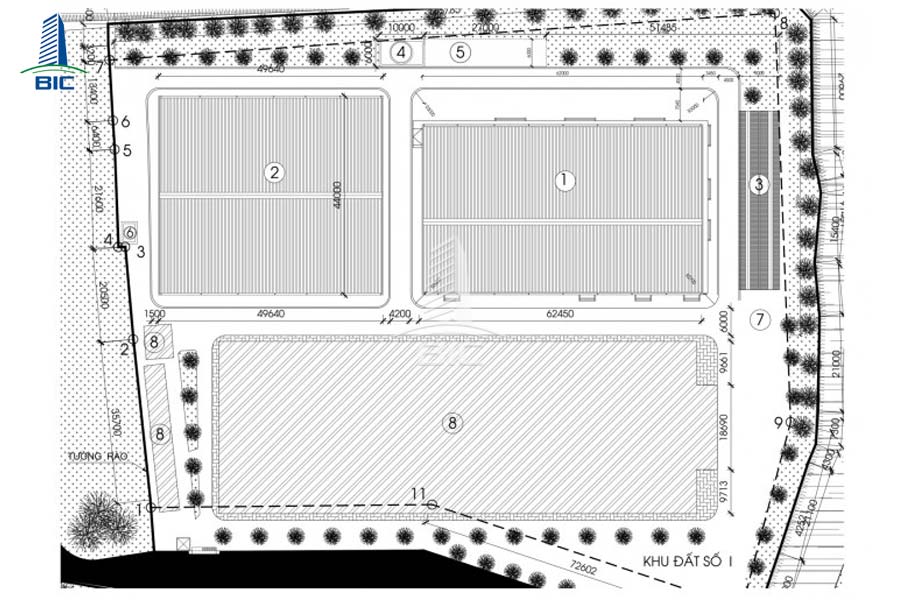

- Estimating the necessary space for each functional area, such as production zones, offices, and storage areas, is essential to avoid wasting or overloading space while ensuring smooth operations.

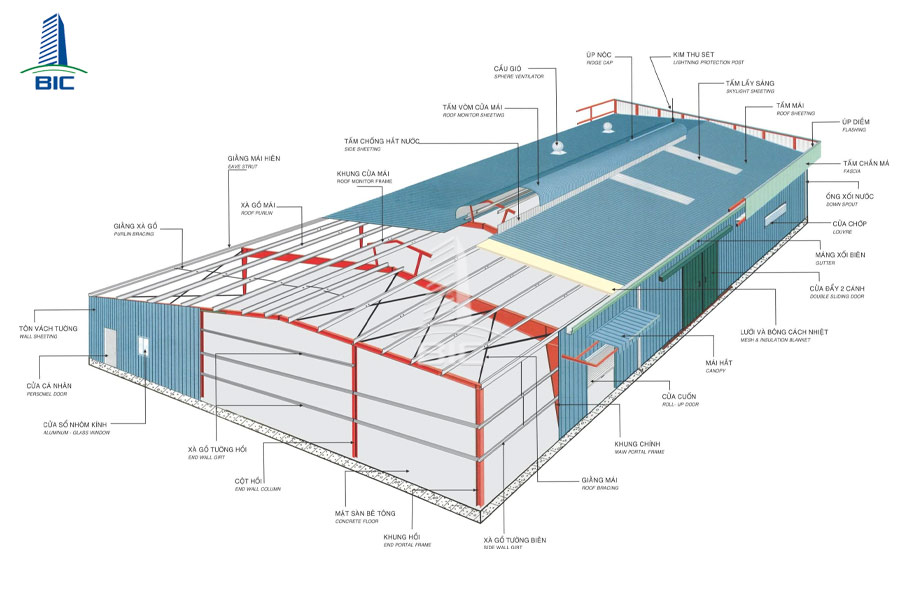

The layout design is the foundation for the success of a small factory. A rational arrangement requires maximizing the available space while ensuring a smooth flow of traffic between areas. One smart approach is using a flow-oriented layout, where materials and products move continuously through the production stages without obstacles. Selecting appropriate construction materials is another aspect to consider. Lightweight materials like thin steel, aluminum, or composites not only reduce structural weight but also save on transportation and installation costs. Additionally, these materials are often durable and easy to work with, reducing construction time. Ventilation and lighting systems are also vital in small factory design. A good ventilation system ensures continuous air circulation, preventing the buildup of exhaust gases and dust while maintaining a stable temperature. Alongside this, natural lighting should be maximized to save electricity and create a comfortable working environment.

Storage space in a small factory must be used efficiently. Utilizing racks and shelving is an ideal solution to take advantage of vertical space, freeing up floor space for production activities and movement. Shelves can be designed with multiple levels, suitable for the height of the factory and the weight of the stored goods. Choosing multifunctional equipment is another way to save space. Equipment that combines multiple functions into one reduces the number of machines needed, thereby reducing installation space and investment costs. Organizing goods scientifically not only helps manage inventory effectively but also enhances workplace safety.

Fire safety is a mandatory requirement in factory design, especially when limited space can make escape routes and fire control more challenging. Installing modern fire alarm and suppression systems is essential. This system must include smoke detectors, temperature sensors, and automatic sprinklers or fire extinguishers suitable for the factory's size. This helps detect and address issues promptly, minimizing damage to property and lives. Escape routes must be logically arranged, easily accessible from all areas within the factory, and clearly marked so that workers can quickly exit in an emergency. Additionally, escape routes should be regularly inspected to ensure they remain unobstructed and meet safety standards. Training employees on how to use fire-fighting equipment and how to evacuate is also crucial in ensuring comprehensive safety for the factory.

Another solution for small factories is to seek and collaborate with reputable factory design firms. Professional companies in the field of factory design often have extensive experience and knowledge of space optimization. They can provide creative solutions tailored to the specific needs of the business while ensuring compliance with safety and legal regulations. Choosing a reputable design firm not only ensures a high-quality design but also saves time and effort during construction. Reputable companies often have good relationships with contractors and material suppliers, helping the project proceed smoothly and achieving the highest efficiency.

When designing and building a small factory, attention to detail is crucial to ensure optimized space and efficient functionality. If you're looking for professional factory design solutions, contact BIC today. With experience and expertise, BIC will advise and provide you with the best design solutions, helping you realize your ideas effectively and safely.