A factory design dossier is a complete set of drawings, technical specifications, and cost estimates prepared to guide the construction process. This set of documents enables investors, engineers, and contractors to accurately determine construction solutions, estimate materials and costs, and ensure the facility meets all technical standards. As BIC emphasizes, the design dossier is the key factor determining the safety, functionality, aesthetics, and investment cost of the project.

Investing in a comprehensive design dossier not only reduces costs but also ensures that the facility operates safely and efficiently in the long term. A well-prepared dossier also shortens the time required for permitting, minimizes construction errors, and facilitates future expansion or renovation.

According to the Construction Law 2014 (amended in 2020), construction design consists of several stages: conceptual design, basic design, and detailed design for implementation (such as FEED, technical design, and construction drawings).

For factory projects, investors may choose a two-stage process (basic design and construction drawings) or a three-stage process (basic design, technical design, and construction drawings) depending on project requirements.

The conceptual design, prepared during the pre-feasibility study, outlines the project’s initial idea and overall direction. It provides preliminary descriptions of the location, scale, functions, technology selection, and main equipment for the factory. It also includes a preliminary site assessment, production line layout, and investment cost estimate. This stage helps both authorities and investors understand the project’s general orientation and make investment policy decisions.

The basic design, developed as part of the feasibility study or technical-economic report, includes preliminary drawings and explanatory documents on architectural, structural, and technical solutions.

The explanatory text summarizes the project’s location, scale, main architectural-structural solutions, production processes, fire safety measures, environmental considerations, and lists the applicable standards.

The drawings typically include site layout, process flow diagrams, architectural concepts, main structural solutions, and technical infrastructure systems (power supply, water supply, drainage, fire protection, etc.).

The basic design dossier is often used to apply for construction permits and serves as the foundation for developing a detailed cost estimate.

This stage elaborates on the basic design after its approval. The dossier includes detailed construction drawings and supplementary technical explanations. These final drawings specify dimensions, materials, structural details, and system components (electrical, plumbing, fire safety, ventilation, etc.) in accordance with applicable standards.

The technical and construction design must include “all technical parameters, materials, and structural details... that comply with the applicable codes and standards, ensuring the project is ready for construction.”

This stage provides contractors with all the necessary information for accurate and efficient construction.

A complete factory design dossier usually includes the following components:

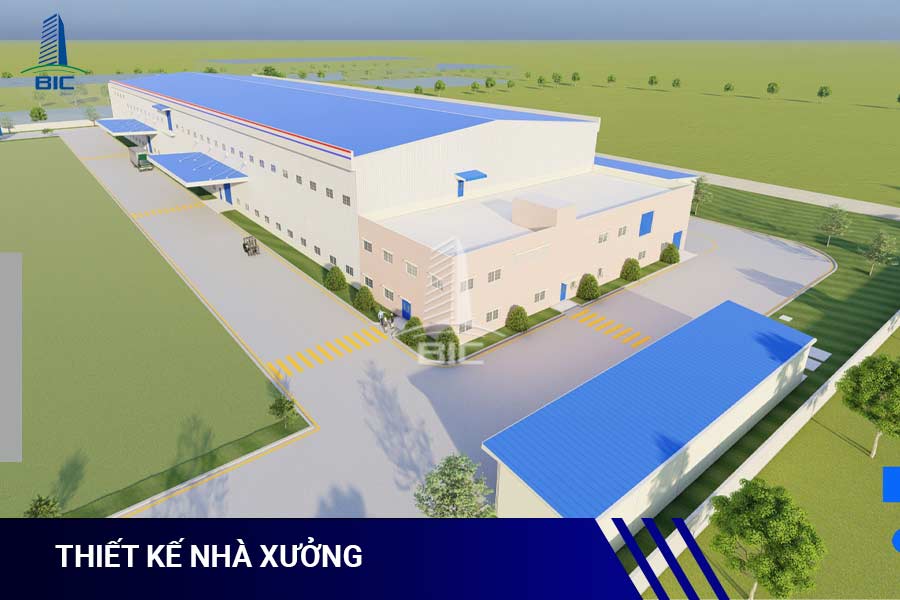

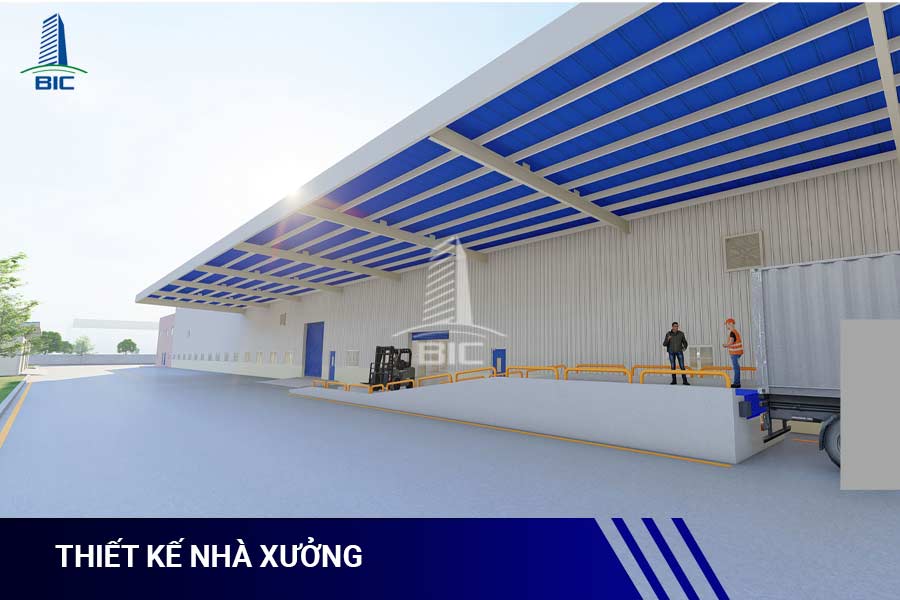

These drawings include the general site plan, floor plans (if applicable), elevations, and sections of the factory. They define the building’s scale, entrances and exits, emergency exits, ventilation, and lighting systems. 3D renderings and diagrams of door layouts, circulation paths, and ventilation solutions are often included to help visualize the building’s overall function and appearance.

Structural drawings include detailed plans of the foundation (footings, pits), main steel frame (columns, beams, roof trusses), floor slabs, and bracing structures.

For pre-engineered buildings, these drawings specify the steel frame system, bracing system, anchor bolts, railings, steel stairs, and other structural components to ensure load-bearing capacity and stability.

The dossier also includes details of steel connections, crane beam layout (if applicable), and other critical elements to ensure precise construction according to technical standards.

The combined mechanical, electrical, and plumbing (MEP) drawings form a crucial part of the dossier. They include:

- Lighting and power distribution diagrams (including transformer stations and control panels)

- Water supply and drainage systems for production and domestic use

- Ventilation and air-conditioning systems

- Fire protection systems, such as fire hydrant networks, sprinkler heads, fire extinguishers, emergency exits, and fire alarm systems

The MEP and fire protection drawings clearly show the layout and routing of pipes, electrical cables, pumps, smoke exhaust fans, and other equipment, enabling contractors to install them correctly and safely.

The design explanatory document details the chosen design solutions. It summarizes the construction site, scale, functions of different zones (factory, warehouse, office, auxiliary facilities), main materials used, and preliminary load calculations. It also addresses fire protection, environmental protection, occupational safety, and main technical solutions.

At the end, it lists the national codes and standards (TCVN, QCVN) applied in the design, such as those for steel structures, concrete, electrical systems, fire safety, and environmental protection. The goal is to clarify the design approach and demonstrate compliance with current regulations.

The cost estimate details the quantities and projected costs for the entire project. It includes quantities of materials (steel, concrete, finishing materials, electrical conduits, etc.), labor, construction equipment, and other expenses.

A detailed cost estimate allows investors to plan budgets, track expenses during construction, and compare contractor bids. The estimate is usually compiled from the quantities calculated based on the design drawings.

The factory design dossier must strictly comply with all current construction standards and codes. Drawings and structural calculations must follow Vietnamese Standards (TCVN) and relevant industry guidelines, such as:

- TCVN 4456: Foundation and footing design

- TCVN 5574: Design of steel-frame industrial buildings

- Standards for industrial electrical systems

- Fire protection codes

- Occupational safety regulations

Additionally, compliance with fire safety (QCVN 06:2023/BXD) and environmental regulations is mandatory. The dossier must clearly demonstrate how these standards are applied to ensure safety, structural integrity, and functionality. Designers must consult legal documents, national construction codes, and industry-specific standards and incorporate them into the explanatory documents and drawings.

A complete and accurate design dossier is the foundation for ensuring the project meets technical requirements, aesthetic standards, and investment efficiency. Investors should work with experienced and professional design firms to prepare a detailed dossier from the earliest stage. Proper investment in the design stage delivers long-term benefits in terms of project quality and cost savings.Contact BIC for professional support with industrial factory design solutions and legal documentation assistance tailored to your specific industry and investment project.