When factory design, steel sheet roofing is a popular choice due to its ease of installation, reasonable cost, and high durability. However, to ensure long-term performance and structural integrity, the slope of the roof plays a critically important role. An inappropriate roof slope can lead to water leakage, rainwater accumulation, reduced building lifespan, and increased maintenance costs.

So what is the standard slope for steel sheet roofs? How do we calculate it correctly, in line with real-world conditions while ensuring safety? In this article, BIC will provide a detailed analysis of the standards for designing roof slopes in industrial buildings, offering useful insights for investors and engineers to develop cost-effective and technically sound solutions.

In any factory design project, the roof is more than just a protective covering, it significantly affects the building's durability, operational efficiency, and long-term maintenance costs. One of the most often overlooked yet vital technical aspects is the roof slope. A properly designed slope ensures effective drainage and contributes to the overall performance of the facility.

A reasonable slope enables rainwater to drain quickly, preventing pooling—one of the main causes of leakage, corrosion of steel frames, and deterioration of roofing sheets. Especially in tropical climates like Vietnam, where rainfall is seasonal and often heavy, proper slope design is essential to protect the structure.

A well-sloped roof reduces water pressure on the sheet surface, minimizing oxidation, corrosion, or sagging over time. This not only protects the structural components but also significantly reduces long-term repair and maintenance expenses especially important for facilities that operate continuously.

A sloped roof facilitates natural drainage, reducing the need for complex water collection systems. Additionally, it helps distribute load more efficiently, allowing for lighter trusses and purlins, thus reducing construction costs without compromising safety.

Each region and building function demands different slope specifications:

- Rain-prone areas require steeper slopes for rapid drainage.

- Hot, dry regions may use medium slopes combined with insulated roofing to reduce heat accumulation.

- Manufacturing, warehousing, and cleanroom areas each require custom roof designs to meet operational needs and protect equipment.

A proper slope is not only a technical specification but a strategic design decision that enhances investment efficiency and building longevity.

Roof slope design must consider not only standard regulations but also real-world conditions at the construction site. Without thorough calculation, an improper slope can result in pooling, leakage, or added stress on structural components. Key factors include:

Each material varies in durability, water flow efficiency, and expansion coefficient:

- Galvanized or cool roofing sheets: smooth surface, easier drainage, suitable for slopes of 10–12% or more.

- Insulated panels (PU, EPS): thicker and heavier, more sensitive to load and expansion, requiring steeper slopes (15% or more) for safety and durability. Choosing the right material directly impacts slope requirements, construction cost, and operational efficiency.

The longer the roof, the less efficient water drainage becomes without adequate slope. For roofs over 15 meters in length, a minimum slope of 10–15% is typically recommended to prevent water accumulation.

In addition, wind loads, roof weight, and other dynamic/static loads must be factored into the design. A suitable slope ensures even force distribution, minimizes deformation, and enhances structural stability.

Climate is a key determinant in slope selection:

- Heavy rainfall areas (e.g., Northern or Central Vietnam): require steeper slopes (15–30%) for rapid water discharge and to minimize leakage.

- Hot, dry areas (e.g., Southern Vietnam): medium slopes are acceptable but should be paired with insulated materials to prevent overheating.

Designing the slope according to climate ensures proper function and extends the life of the building.

The purpose of the facility directly influences roof slope needs:

- Manufacturing plants: require efficient water runoff to protect machinery and internal processes.

- Warehouses: need robust waterproofing and humidity control.

- Cleanrooms and technical areas: require steeper slopes with closed drainage systems and dust-resistant coatings.

Understanding intended use from the outset allows engineers to recommend optimal roofing solutions that save costs and improve operational performance.

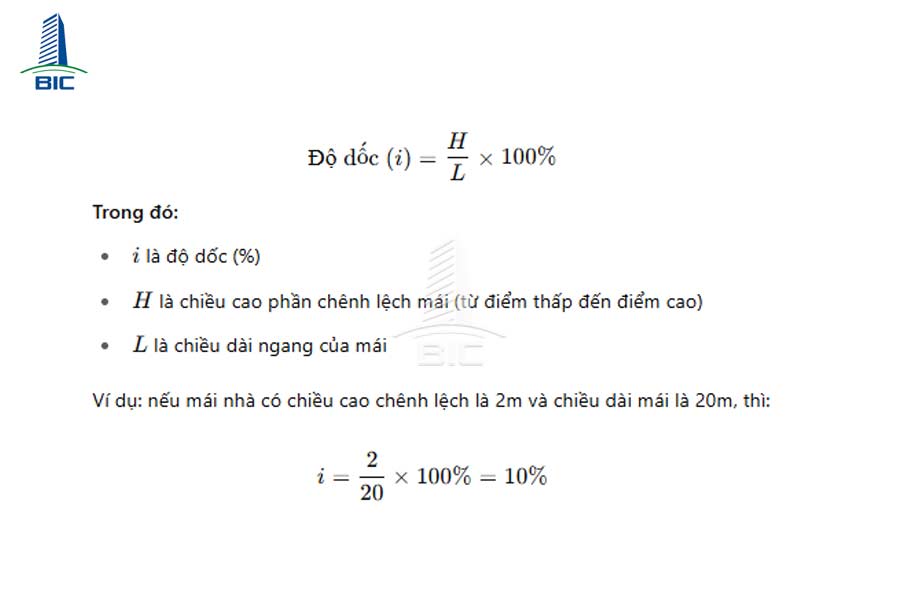

Designing a roof slope should not rely solely on intuition or experience. It requires clear and precise calculations based on roof dimensions, functional requirements, and specific technical conditions. Below is a detailed guide on how to calculate and choose an appropriate roof slope:

First, it’s important to distinguish between slope percentage (%) and slope angle (°). In industrial building design, slope is typically expressed as a percentage because it is more intuitive and practical for real-world applications.

- Single-slope roof: Simple and easy to construct, suitable for small-scale factories or areas with favorable drainage conditions. However, it's important to carefully assess wind loads and drainage direction.

- Double-slope (A-frame) roof: Ideal for larger factories, as it allows water to drain on both sides and creates better load balance for the structural system. The slope is evenly distributed across both sides, and calculations should account for the total length (L) of both slopes.

- Asymmetrical or curved roofs: Commonly used in custom or architectural designs. Each side requires separate slope calculations and must be closely integrated with a drainage system to prevent localized leakage.

Roof slopes in industrial building design must adhere to technical standards issued by the Ministry of Construction, particularly within the Vietnamese Construction Standards (TCVN). Following these standards ensures proper drainage, extends roof lifespan, and minimizes long-term operating costs.

Based on current regulations and manufacturer guidelines:

- Galvanized or cool roofing sheets: 10–15% slope for medium roof spans and moderate rainfall.

- 3-layer insulated panels (PU, EPS): 15–30% slope to handle greater weight and ensure quick drainage.

- Long-span roofs (>20m): minimum 15% slope required to prevent pooling and stress on trusses.

If using roofing materials with low drainage capacity (e.g., shallow corrugations), increase slope to compensate.

|

Roof Length (m) |

Recommended Slope (%) |

Notes |

|

< 10m |

10% – 12% |

Single-slope or small-scale roofs |

|

10m – 20m |

12% – 18% |

Standard industrial applications |

|

20m – 30m |

15% – 25% |

Requires coordinated drainage design |

|

> 30m |

25% or more |

Recommend double-slope configuration |

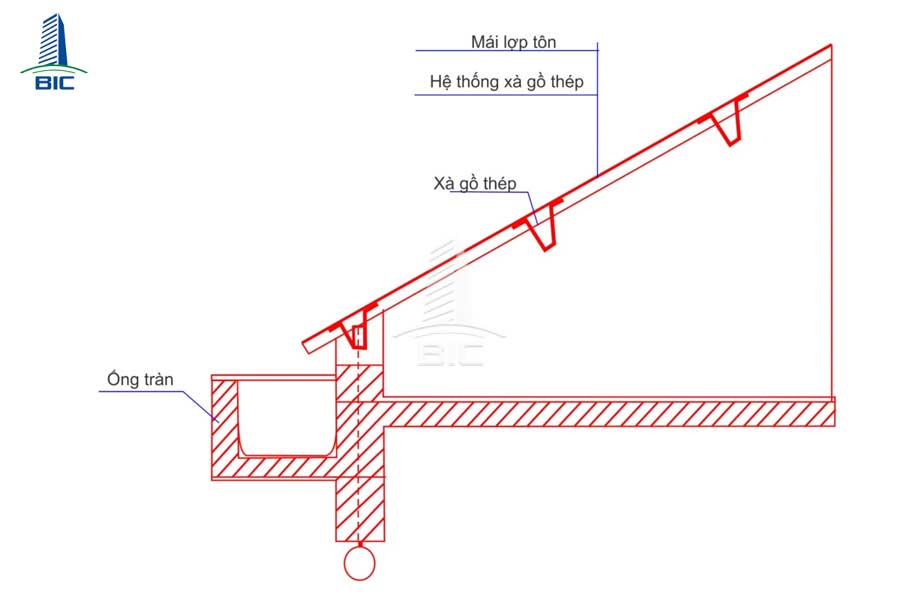

Choosing the correct slope is only the first step. For optimal water management and long-term performance, the slope must be supported by a synchronized drainage and structural system:

- Should be placed at the roof's lowest point for maximum water collection.

- Must have sufficient cross-section to handle peak rainfall.

- Use rust-resistant, durable materials to prevent leakage and blockage.

- Design based on maximum rainfall in the region.

- Drainage channels should be covered (if in traffic zones) and fitted with debris screens to avoid clogging.

- Use deep-ribbed, high-wave roofing sheets for better drainage.

- Install EPDM rubber-sealed screws to prevent leaks at penetration points.

- Apply waterproof silicone at joints and overlaps.

A well-integrated design between slope, structure, and drainage minimizes technical risks, reduces maintenance costs, and significantly enhances the overall longevity of the facility.

Despite its importance, roof slope design is often underestimated leading to frequent issues such as leakage, accelerated deterioration, and rising repair costs. Common pitfalls include:

This is the most frequent mistake, especially in large buildings. Roofs over 20m with slopes below 10% risk severe pooling, corrosion, and even collapse under heavy rain accumulation.

Designs based on theory alone often fail to account for:

- High rainfall zones: require steeper slopes to evacuate water effectively.

- Wind-exposed areas: need reinforced structural connections and optimized slope angles to resist uplift.

Even with proper slope, inadequate or mismatched drainage (e.g., small gutters, no debris filters) can result in interior flooding. All drainage elements must be designed as a unified system.

Even with correct slope design, errors in execution can cause rapid deterioration:

- Using non-sealed screws instead of waterproof ones.

- Installing panels against water flow direction.

- Choosing thin or low-quality roofing not suited for industrial loads.

Avoiding these mistakes is essential for structural integrity, uninterrupted operations, and long-term cost savings.

To ensure structural durability, operational efficiency, and long-term savings, investors should adopt comprehensive design construction strategies:

- Match slope to building dimensions and site conditions.

- Design gutters, downspouts, and channels in sync with water flow rates.

- Integrate overflow control, debris screens, and covered drains to avoid clogging.

- Ensure slope aligns with construction standards.

- Select materials and structures suited to wind, rain, and heat loads.

- Recommend material-efficient, cost-saving solutions without compromising safety.

Tailoring the slope design to the specific facility helps avoid misfits and unexpected costs during implementation.

Modern tools like Tekla, SAP2000, and Etabs enable:

- Simulation of wind and rain loads.

- Analysis of deflection, flow efficiency, and joint durability.

- Early risk detection and design optimization.

Technology enhances accuracy and significantly reduces post-construction maintenance costs.

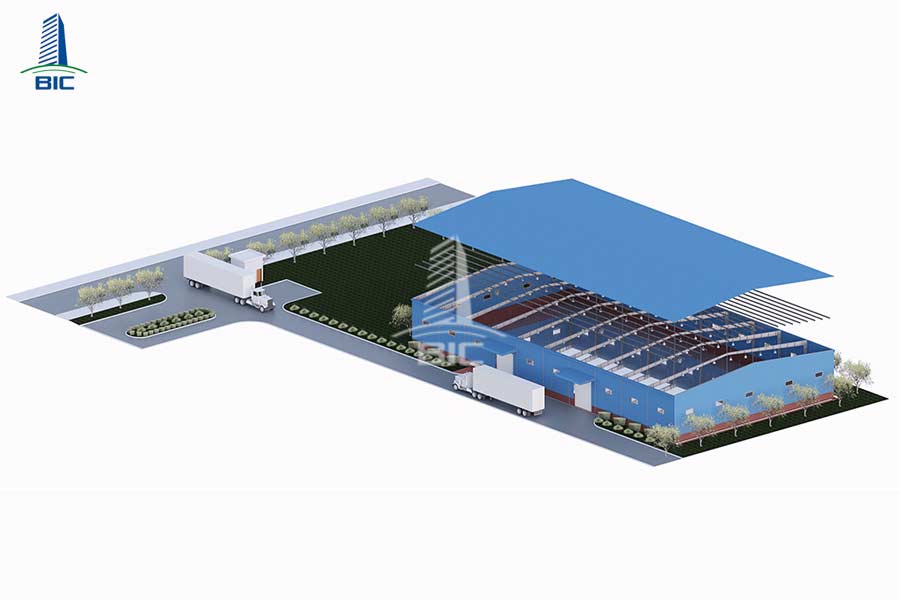

An optimized industrial building design goes beyond the architectural drawing, it lies in every technical detail, especially the roof slope, which determines structural durability, water drainage, and investment effectiveness.

With years of experience in industrial facility design and construction, BIC is committed to delivering end-to-end solutions that meet both technical standards and operational demands. From survey and design to turnkey execution, we ensure quality, timeliness, and cost-efficiency for every project.