Before commencing construction and construction, the first thing to do is to draw up the design. The blueprint will help the construction process go smoothly. At the same time, ensure progress and quality of the project.

.jpg)

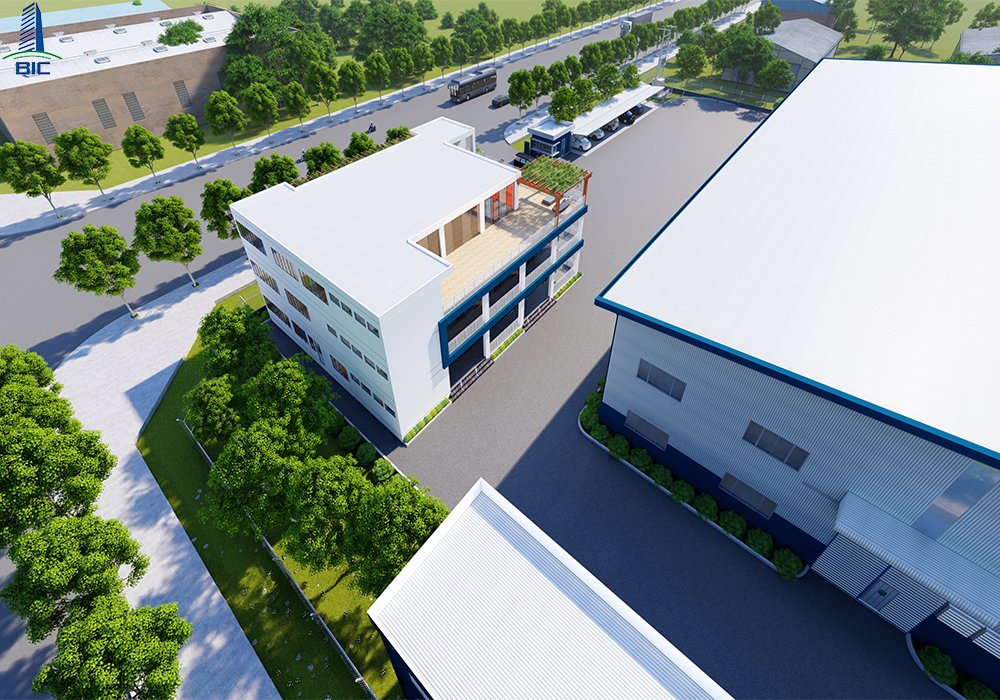

Workshop design overview

When designing a workshop, the design unit needs to ensure the following factors:

Convenient in the process of installing machines and equipment for future use.

Meet all the requirements according to the regulations on area; size; space height; ground structure; production area; ...

Ensure the conditions such as ventilation, height, taking advantage of a lot of light, ...

Good sound and vibration insulation; avoid sound, noise from outside, affecting the production process.

Ensure durability and firmness to be able to withstand the impact during work.

Good insulation design to ensure cool in summer and warm in winter.

Factory design basic process

This process consists of 2 basic steps as follows:

Step 1: Design the initial overview drawing

The overview drawing will help businesses better visualize the project. Things to prepare before designing: general description of the whole project; plans for machines, equipment and technology; options related to other projects.

After preparing everything completely, start painting the main face of the building; Architecture projects; Main structure design and infrastructure, engineering.

Step 2: Design drawing for construction

After completing the general drawing, it is necessary to design the drawing for construction. To do this, it is necessary to: develop design documentation; detailed design drawings; project estimate; related documents.

Factory design drawings

To complete the project on schedule and still ensure the quality, it is necessary to have a methodical plan for the construction process. Basically, the factory construction process will include the following 6 basic steps:

1. Construction of the foundation

Ground leveling: this is the first thing when constructing the factory. Depending on the condition of the ground, the contractor will level the ground to match the technical drawing.

Positioning the center of the axis: the column foundation positions will be based on this column for construction. That is why this is very important work.

Fence digging: Most factories often have very long fences. Therefore, the foundation of the fence needs to be calculated and constructed firmly.

Construction of foundation and braces: foundation construction is carried out based on the positioned shaft heart. This foundation can be a single foundation or a pile foundation; Construction material is reinforced concrete. This step, proceed to bury the bolts in the foundation to later join the steel column.

Compounding ground soil: After being leveled, the soil will be compacted to correct the compactness.

Stone foundation: Usually the workshop floor is reinforced concrete placed on the stone foundation that has been compacted enough. The thickness of this rock layer will be specified in the design.

Construction of the workshop foundation: Progress the goods to build the reinforcement and pour concrete for the foundation. After pouring concrete, it is necessary to carry out proper maintenance to avoid cracking and leaking on the floor.

Ground leveling

Foundation construction

2. Steel frame construction

Currently, the factory frame is usually constructed with steel frame. These steel frames will be strictly controlled for quality before being used for assembly in factories. The way to assemble the steel frame is as follows:

Steel frame erection: The parts of the steel zone will be connected together by bolts. Because the steel frame is very large and heavy, it is necessary to use a crane for assembly.

Mounting purlins and bracing cables: The bracing system will fix on out of the frame plane. Purlin system is used to enhance the stability of steel frames and support roofing.

Steel frame construction for the workshop

3. Construction of cover

The shell consists of brick wall; corrugated iron roof; ... steps include:

Surrounding walls

Roofing or other material as required by the design.

Construction of the roof

4. Construction of infrastructure

Factory infrastructure is very important, it affects the operation later on. The basic infrastructure for the factory will include: roads; water supply and drainage pipes; ... The work to be done is: installing water pipes; roadbeds; roadbed stone; curing concrete on the roadbed and cutting the seals against cracking.

5. Construction engineering system

When constructing the factory, the technical system is an indispensable part. This system will include systems such as: fire protection; communications; electricity and water; technical system for production; ...

6. Finishing

This is the last stage in the factory construction process. At this step it is necessary to do the following:

Markers: help separate traffic lanes, goods in the workshop.

Close the plaster ceiling for the office building.

Decorate the area around the factory such as planting trees, flowers and grass.

Conducting cleaning the entire workshop before handing over.

Performing stages before handing over

Thus, in order to construct the factory smoothly, businesses and units need to prepare many things. From matters that need to be considered before construction such as construction cost; blueprints for other works during construction. Therefore, businesses as well as contractors need to have careful calculations to ensure the quality of works with the most appropriate cost.

BIC is a company specializing in the design and construction of high-quality factories, pre-engineered steel buildings, industrial warehouses. In addition, BIC also designs and constructs office buildings, participates in surveying, testing,...

BIC has participated in many construction projects across the country. We have a lot of experience in building large-scale projects of famous investors from countries around the world such as Japan, Korean, Taiwan, America (USA), Singapore,...

BIC's reputation has been strengthened more and more as we are known more for its professional attitude, seriousness, integrity and honesty in business. BIC is now a trusted brand name for well-known investors in the Vietnamese market.

Benefits of Customer:

We have been implementing large-scale factory projects from 70,000 square meters to more than 200,000 square meters of foreign enterprises investing in Vietnam such as: Korean, Japan, Taiwan, .... We more and more efforts to become one of the leading brands in terms of prestige, project implementation capacity in Vietnam, reaching out to markets in countries in Southeast Asia and the World.

BIC is committed to providing customers with the best building service, office building, high-rise apartment building. By the enthusiasm and unrelenting efforts of all officials and employees. Especially, we have conquered many big projects and gained the confidence and satisfaction of the "Big Men" in the world who came to Vietnam to invest in the construction.

BIC is very pleased to serve you with the spirit: "COOPERATE TO DEVELOP TOGETHER"

BIC is constructing an industrial factory

BIC CONSTRUCTION ARCHITECTURAL JOINT STOCK COMPANY

Ho Chi Minh Branch: 7th Floor, Gia Dinh group, 566 National Highway 13, P.Hiep Binh Phuoc, Thu Duc District, Ho Chi Minh City

☎️ Hotline: 0901.815.069

Mail marketing: marketing@bicons.vn

Hanoi Branch: 4th Floor, HUD3 Tower, No. 121-123 Pho To Hieu, Ha Dong District - Hanoi.

☎️ Hotline: 0243.91.92.789

Mail: bic@bicons.vn - Fax: (028) 38 800 892

Mail marketing: marketing@bicons.vn