In the process of factory construction, the metal sheet roof is always considered one of the most important components, as it directly determines the durability, weather resistance, and long-term operating costs of the building. A suitable roof not only protects the factory from sun, rain, and storms but also helps regulate temperature, reduce noise, and save energy. Therefore, choosing the right type of factory roof from the design stage plays a vital role in production efficiency as well as the building’s lifespan.

In reality, there are many types of metal sheet roofs applied in factory design, ranging from trapezoidal roofing sheets, corrugated sheets, insulated sheets, cold-rolled sheets, to skylight roofing. Each type has its own advantages, suitable for different production needs and scales. If a business only focuses on initial costs while neglecting technical and functional aspects, it may face rapid deterioration, rising repair expenses, and production disruptions.

With extensive experience in construction design, BIC always accompanies businesses in consulting and selecting suitable roofing solutions. Beyond ensuring durability and safety, BIC emphasizes energy efficiency and sustainability, helping projects optimize investment costs while maintaining long-term effectiveness. This is an essential step in any factory construction project, especially for large-scale facilities where structural and functional calculations must be carefully considered.

A roof is not just a protective cover but also a crucial component that determines the long-term operational efficiency of a factory. With the unique characteristics of industrial production, a metal sheet roof serves multiple functions: shielding against harsh weather conditions, ensuring structural durability, regulating indoor temperatures, and reducing operating costs.

A properly designed roofing system helps maintain a stable working environment, limiting heat, dampness, or leakage. Moreover, choosing the right roofing material enhances the lifespan of the steel frame, walls, and other structural elements. For businesses investing long term, a high-quality roof is a key factor in saving maintenance costs and reducing production interruptions.

Beyond protection, a roof also contributes to aesthetics and adds value to the project. Modern solutions such as insulated sheets, skylight sheets, or color-coated sheets not only enhance operational efficiency but also demonstrate professionalism and scale in the eyes of partners.

With hands-on experience from numerous industrial projects, BIC provides roofing solutions tailored to each business’s real needs. By integrating technical, functional, and aesthetic factors, BIC ensures that factories are not only durable and safe but also operate efficiently over the long term.

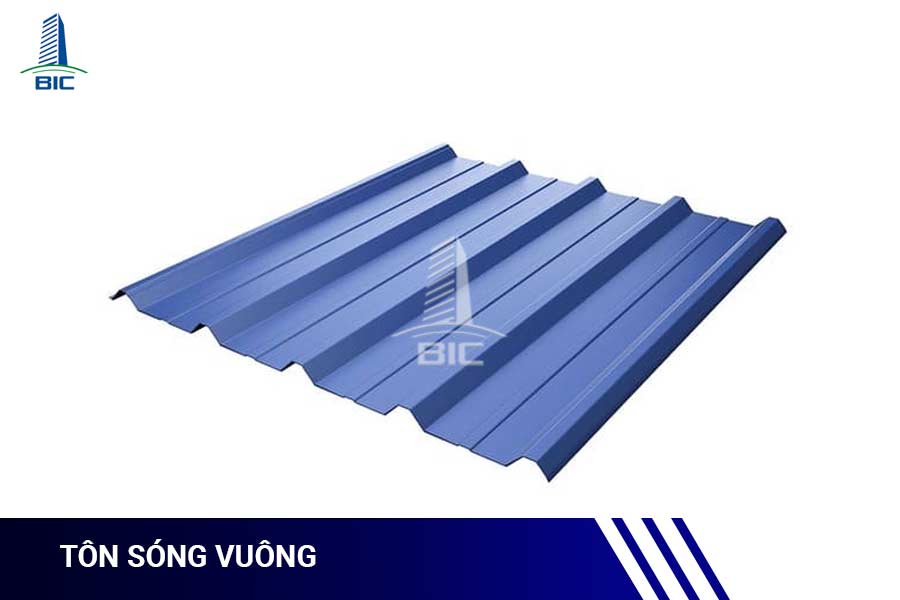

These have high, square waves that increase load-bearing capacity and impact resistance. Widely used in large-scale factories, they ensure both durability and easy installation. Thanks to their efficient water drainage, trapezoidal sheets prevent water accumulation and rust, prolonging the roof’s lifespan. They also come in various sizes and thicknesses to suit different budgets and structural needs.

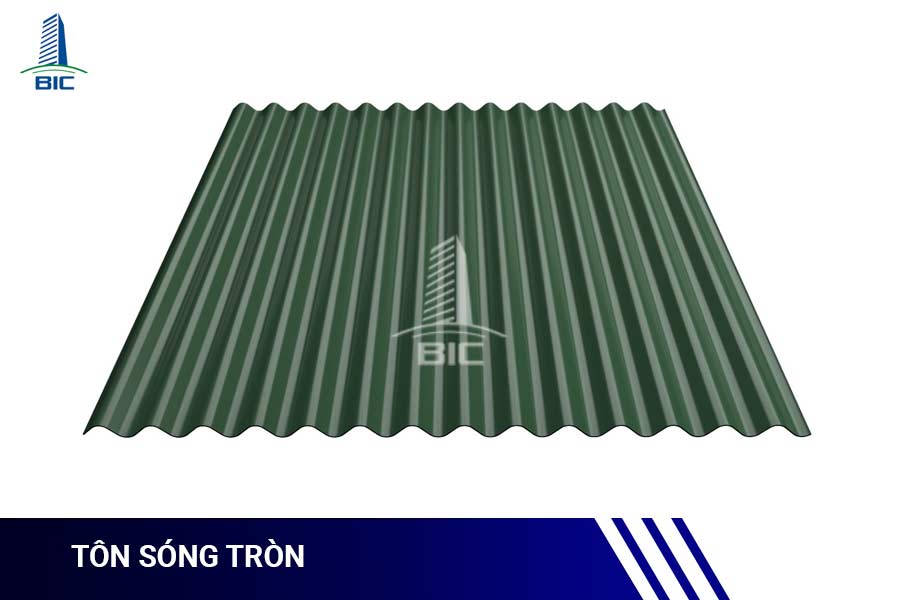

This long-used roofing type is common in residential and small-scale factories. Its curved waves allow effective water drainage, minimizing leakage during rainy seasons. However, due to limited load-bearing capacity, corrugated sheets are less suitable for modern large-scale projects. Businesses choosing this option should carefully consider roof load and local climate conditions.

These consist of multiple layers, including an insulating material such as PU or foam. They reduce indoor temperatures by 5–10°C compared to normal sheets, block heat absorption, and minimize noise from rain and wind, creating a more comfortable working environment. Ideal for industries requiring controlled temperatures such as food, pharmaceuticals, textiles, and electronics.

- Cold-rolled sheets feature aluminum-zinc coating, reflecting heat and keeping factories cooler.

- Galvanized sheets provide high rust resistance, suitable for humid or coastal areas.

- Color-coated sheets combine oxidation resistance with aesthetic value, allowing businesses to align factory colors with brand identity.

These materials are preferred in modern projects due to their durability and aesthetics.

Made from transparent or translucent polycarbonate, skylight sheets are installed alternately with other roofing materials to maximize natural light. This significantly reduces daytime lighting costs while creating a bright and airy workspace. In large factories, strategic skylight installation can save tens of millions of VND in electricity costs monthly. However, careful material selection and placement are required to prevent brittleness or cracking under harsh weather.

Each production type has unique requirements. For instance, food, pharmaceutical, or electronics factories need cool, stable environments and thus require insulated sheets. Meanwhile, mechanical factories or warehouses may use trapezoidal or galvanized sheets to save costs. Roofing must align with the actual needs and production characteristics of the business.

In hot and humid climates, roofing should provide strong insulation to reduce cooling costs. Insulated or cold-rolled sheets are preferable. Durability is also critical, as large factories are long-term investments requiring rust-resistant, corrosion-resistant, and high-strength materials.

Many businesses focus only on installation costs, neglecting maintenance expenses. Cheap sheets may deteriorate quickly, causing leaks, production disruptions, and early replacement costs. Investing in high-quality materials such as color-coated or insulated sheets helps reduce repair and maintenance costs, saving more in the long run.

Roofs must match the overall design in terms of structure, slope, and drainage systems. An incompatible roof can lead to leaks, sagging, or collapse under strong winds. For businesses prioritizing brand image, color-coated sheets or skylight roofs add both functionality and aesthetic value.

A slope of at least 10% is recommended to ensure quick water drainage. Too little slope causes water stagnation and stress, while too much slope increases structural and construction costs.

Along with suitable roofing, natural ventilation or industrial exhaust fans should be installed to reduce heat accumulation, save cooling costs, and maintain comfortable working conditions.

The steel frame bears the roof load. If poorly designed, the roof may sag, sink, or fail under strong winds. Structural loads must be carefully calculated, using standard-grade steel and secure installation.

In storm-prone regions, roofing must be firmly anchored with storm-resistant screws or high-strength bolts. Additional bracing, purlins, and anchoring systems help prevent roof uplift during extreme weather.

Installation should be carried out by skilled workers with full protective equipment, while ensuring shielding for workers and equipment below during construction.

A professional contractor plays a decisive role in ensuring roofing quality. They not only advise on the best type of sheet but also calculate steel framing, roof slope, drainage, and ventilation systems for overall compatibility.

Experienced firms help minimize risks, control costs, and ensure roofs are installed to technical standards, extending the building’s lifespan. By applying international standards and modern technologies, they also ensure safety, aesthetics, and sustainability.

Most importantly, a trusted partner supports businesses throughout the building’s lifecycle, from surveying, design, construction, to maintenance, renovation, and expansion.

The roof is one of the most critical components of a factory, directly affecting durability, operation, and long-term costs. Choosing the right type of roof, combined with proper technical design, ensures a sustainable, energy-efficient, and productive facility.

To achieve this, working with a reputable construction design partner is essential. With proven expertise in industrial design and construction, BIC always supports businesses in selecting optimal roofing solutions, ensuring safety, quality, and long-term effectiveness. This provides a solid foundation for businesses to operate confidently and strengthen competitiveness in the market.