The pressure to optimize cash flow and accelerate project commissioning is forcing the construction industry to fundamentally shift its mindset. Traditional construction methods, though familiar, are increasingly revealing major limitations in load capacity, thermal performance, and completion speed. The transition toward next-generation materials is no longer a passing trend but a critical requirement to ensure the long-term economic efficiency of any project. This is the moment when the role of construction contractors is being redefined through their ability to adopt and apply advanced material technologies.

In practice, selecting the right materials from the earliest stages directly impacts future operating costs. A modern industrial facility must integrate lightweight, high-performance materials with excellent thermal insulation to reduce foundation loads and optimize energy consumption. Therefore, reputable industrial construction contractors consider mastery of material technology a strategic competitive advantage that delivers tangible value to clients. In the following article, BIC provides a deeper analysis of the rising trend of new materials in construction design, offering investors a comprehensive perspective for making well-informed partnership decisions.

The construction industry is at a crucial turning point as traditional development models struggle to keep pace with rapid urbanization and increasingly stringent market demands. The shift toward high-tech material solutions is not a temporary movement, but an inevitable outcome of economic and technological evolution.

Construction methods based on traditional materials such as fired clay bricks or cast-in-place reinforced concrete are reaching their performance limits. The inherent weight of these materials requires complex foundation systems and significantly increases soil improvement costs.

Furthermore, wet construction processes extend project timelines and rely heavily on weather conditions and labor skill. Environmental issues caused by dust, noise, and non-recyclable waste are becoming major legal obstacles, especially for projects in urban areas or green industrial parks.

The global economic landscape has introduced new metrics for measuring project success, with green standards and ESG (Environmental – Social – Governance) indicators playing a central role. Investors especially FDI enterprises face strong pressure to comply with sustainability commitments to access preferential capital sources and meet global supply-chain requirements.

Adopting environmentally friendly, recyclable, and low-carbon materials is the most direct path to achieving reputable green certifications such as LEED or Lotus. This is no longer an optional enhancement but an essential criterion for increasing asset value and liquidity in industrial real estate.

These macro shifts demand a new mindset in the partnership between investors and contractors. A competent contractor today is not simply an executor of technical drawings.

They must act as strategic advisors, participating from the conceptual stage to propose intelligent material solutions. The ability to conduct cost-benefit comparisons, forecast energy efficiency, and recommend optimal construction methods using new materials is the core value that a professional contractor delivers helping investors avoid unnecessary waste from the very beginning.

Technological advancements have introduced high-performance materials that are gradually replacing outdated, inefficient solutions. A capable contractor must not only execute construction but fully understand the technical properties of each material to recommend the most suitable solution. Below are major categories of advanced materials reshaping modern building design:

The concepts of green concrete and non-fired bricks extend beyond environmental benefits and offer structural advantages. The most typical examples include autoclaved aerated concrete (AAC) and lightweight aggregate concrete, which have air-cell structures that reduce density to one-third of traditional fired bricks.

AAC significantly reduces dead load on beams, columns, and foundations, enabling structural optimization and material savings. At the same time, its porous structure enhances natural sound and heat insulation, creating comfortable and quiet indoor environments.

Pre-engineered steel structures dominate the industrial sector, especially for large-scale factories. Modern metallurgy has produced high-strength steel that offers superior load-bearing capacity with smaller cross-sections.

The greatest advantage is the ability to achieve large spans without intermediate columns—an essential factor for manufacturing lines and logistics layouts. All components are CNC-cut and factory-welded, then assembled on-site using bolts, minimizing weather dependency and ensuring rapid, high-precision construction.

Glass has evolved from a simple daylighting material into an effective thermal shield. Low-E and Solar Control glass is coated with ultra-thin metallic layers at the nano scale.

These coatings allow visible light to pass through while blocking infrared heat and UV rays. As a result, buildings benefit from natural daylight without heat gain, reducing HVAC loads and energy costs. Energy-saving glass balances aesthetics and performance for office buildings and high-tech factories.

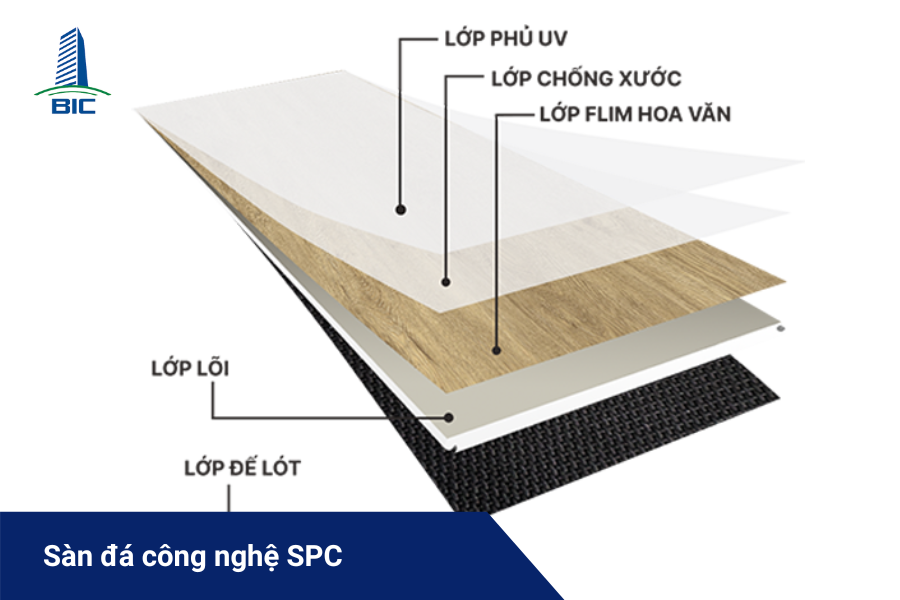

Surface finishing determines both durability and visual quality. Modern design trends favor smart engineered materials such as SPC flooring, WPC outdoor decking, and sintered-stone slabs.

Unlike natural materials that degrade under moisture or termites, these engineered materials offer waterproofing, scratch resistance, and high impact tolerance. Their diverse patterns wood grain, stone grain, concrete effects provide design flexibility, while click-lock systems enable clean, fast installation and easy replacement.

Industrial facilities require durability, rapid commissioning, and strict operational cost control. New-generation materials provide optimal solutions and mark a major shift in design philosophy.

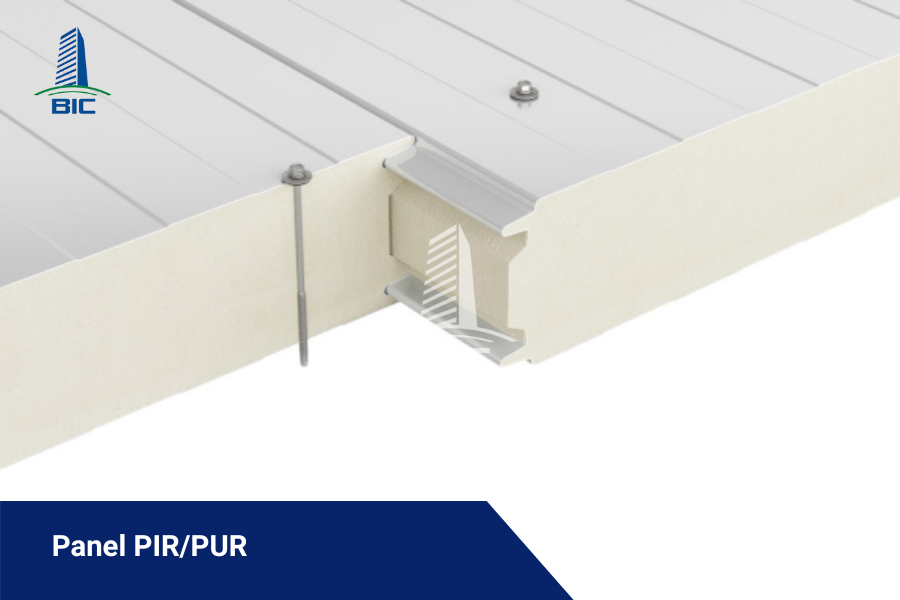

Lighting and cooling consume a large portion of operational budgets. Traditional materials like metal sheets or fired brick walls often suffer from poor thermal performance, causing significant energy loss.

Modern factory design prioritizes eco-roofing sheets, insulated metal roofs, and PIR/PUR panels with extremely low thermal conductivity. These materials stabilize indoor temperatures, reduce HVAC loads, and protect machinery from excessive heat. Well-designed building envelopes can save 20–30% of monthly electricity costs.

Time is money for investors. The sooner a factory operates, the sooner it generates profit. New material solutions such as high-strength steel and precast concrete demonstrate exceptional advantages in construction speed.

Pre-engineered steel components and lightweight concrete panels (Acotec, ALC) are produced at the factory and assembled on-site, shortening structural completion time by 30–50% compared to conventional methods.

Industrial environments involve chemicals, humidity, and vibration. Traditional materials degrade quickly, causing corrosion or cracking.

New materials focus on high corrosion resistance and mechanical durability, such as fire-resistant coatings, aluminium-zinc alloy steel, and hardened polished concrete floors. These enhancements extend the facility’s lifespan by decades and reduce maintenance frequency.

Transitioning to modern materials requires specialized expertise. An inexperienced contractor can easily turn premium materials into costly waste.

The most reliable measure of a contractor’s capability is their track record. Investors should evaluate previous large-scale industrial projects where advanced materials were successfully applied.

Experienced contractors can anticipate risks and optimize material quantities—saving substantial costs for investors.

Unlike traditional masonry methods, new materials demand millimeter-level precision. Contractors must have a well-trained engineering team who understands material properties and can propose safe, efficient solutions. Proficiency in modern lifting equipment and laser measurement is also essential.

A contractor’s confidence is reflected in its warranty policy. For new-technology projects, risks arise not only from materials but from installation techniques.

Investors should prioritize contractors offering clear and extended warranty terms, periodic inspections, and rapid issue resolution to ensure uninterrupted factory operation.

The widespread adoption of next-generation materials in industrial construction is reshaping investment efficiency. This is not merely an aesthetic shift but a strategic advancement toward green, low-cost, and high-performance facilities.

However, material technology only reaches its full potential when executed by skilled craftsmen and technically proficient management teams. A reputable contractor is both a builder and a strategic partner who transforms concepts into durable, safe structures. Choosing the right partner from the outset is the key to eliminating risks and maximizing capital efficiency.

If you are seeking a comprehensive solution to optimize both budget and operational performance, BIC is ready to accompany you. Our experienced specialists are prepared to propose breakthrough industrial-facility designs grounded in advanced material technologies. Contact BIC today for detailed consultation and transform your project into a new benchmark of quality and efficiency.