Many factories constructed in earlier periods no longer meet current requirements in terms of functionality, technical standards, and operational efficiency. When production expansion or equipment upgrades become necessary, investors are often faced with the choice between renovating an existing factory or constructing a new one. This decision has a direct impact on investment costs, project timelines, and the ability to maintain continuous production operations.

Factory renovation is increasingly favored by businesses because it allows them to utilize existing structures, shorten construction time, and reduce initial capital pressure. However, for a renovation solution to be truly effective, the role of factory design and construction design must be carefully considered from the outset. A suitable design approach enables accurate assessment of renovation feasibility, cost control, and compliance with current technical standards.

In the following article, BIC will analyze why factory renovation can be a more reasonable option than building a new factory, while also clarifying the key factors investors should consider before making a decision.

Most factories built many years ago were designed only to meet basic production needs at the time of investment. As technology evolves, new production lines require more flexible spaces, higher load capacities, and more integrated technical systems. Many existing facilities show limitations in working height, layout organization, ventilation, and lighting. These factors directly affect productivity, safety, and overall operational efficiency.

Investment costs for factory construction continue to rise due to fluctuations in material prices, labor costs, and increasingly stringent technical requirements. In addition, extended project timelines increase indirect costs and disrupt production planning. For many businesses, production interruptions during new construction pose significant risks to cash flow and customer commitments. These pressures force investors to carefully weigh the options between new construction and renovation.

In many industrial parks, available land is becoming increasingly scarce and land rental costs are rising. Finding new locations that meet planning requirements and infrastructure conditions is no longer as easy as before. In this context, renovating existing factories becomes a practical solution that allows businesses to maximize the use of available land, avoid additional land-related costs, and shorten project preparation time.

Regulations related to safety, fire protection, environmental protection, and working conditions are continuously updated. Many older factories no longer fully comply with these requirements, creating challenges in approval and operation. Upgrading to meet new standards is therefore a mandatory requirement for businesses seeking stable and compliant operations. Factory renovation combined with professional construction design enables investors to meet legal requirements while improving overall building quality.

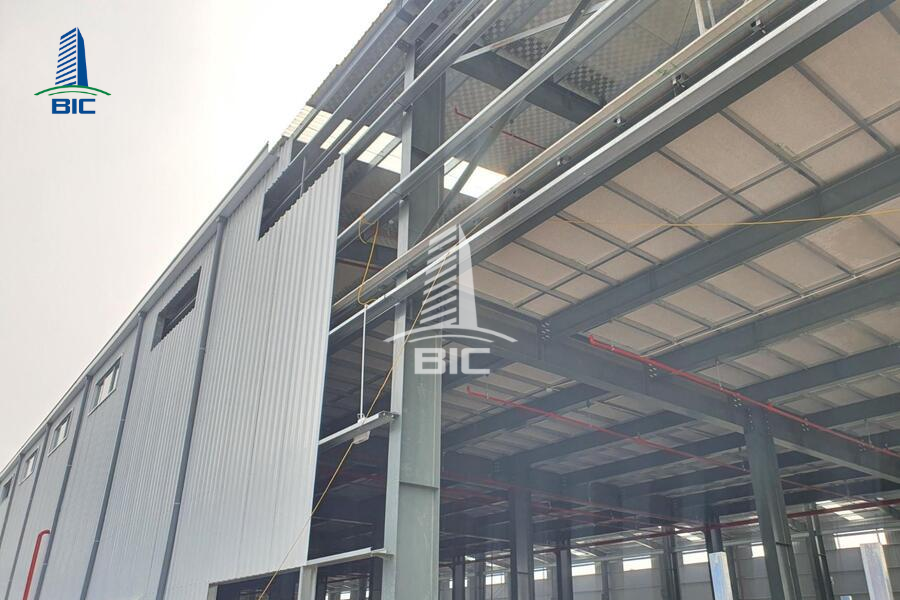

Factory renovation is the process of assessing the condition of an existing facility and proposing construction design solutions to upgrade functionality, structure, and technical systems in order to meet new production requirements. From a design perspective, renovation is not merely localized repair but involves reorganizing space, adjusting structural elements, and upgrading technical systems based on the building’s load-bearing capacity and actual conditions. Factory design plays a decisive role in defining the appropriate scope of intervention and controlling investment costs.

The scope of factory renovation may vary depending on the level of deterioration and usage requirements. Common works include structural strengthening, roof and envelope upgrades, production layout adjustments, electrical and plumbing upgrades, ventilation improvements, and fire protection system upgrades. In some cases, renovation may also involve floor area expansion or the addition of new functional zones. Clearly defining the scope of renovation helps investors proactively manage budgets and implementation schedules.

Compared to building a new factory, renovation typically requires lower investment costs by leveraging existing foundations, frames, and infrastructure. Construction time is also shorter since not all components need to be built from scratch. In addition, renovation reduces the risk of production disruption and short-term capital pressure. However, renovation requires thorough surveys and careful design to avoid unexpected costs arising from complex existing conditions. New construction, while offering greater design flexibility, involves higher costs, longer timelines, and increased risks related to schedules and cash flow.

Factory design plays a foundational role in determining whether an existing facility is suitable for renovation. Through surveys and design analysis, factors such as structural load-bearing capacity, foundation conditions, working height, and layout reconfiguration potential can be quantitatively assessed. These results help investors clearly understand the technical limits of the facility, define a feasible renovation scope, and avoid impractical solutions that lead to cost overruns.

Construction design for renovation not only meets new usage requirements but also maximizes the reuse of existing components. Selecting appropriate structural solutions, reorganizing production layouts, and integrating technical systems according to actual conditions helps reduce demolition and new construction volumes. A well-prepared construction design also supports accurate cost estimation, balanced investment planning, and compliance with current technical standards.

In renovation projects, cost overruns often arise from poor coordination among design disciplines. When architectural, structural, MEP, and fire protection systems are closely coordinated from the design stage, technical conflicts during construction are significantly reduced. An integrated design enables contractors to execute works according to approved documents, minimizes on-site changes, and keeps costs within the planned budget—an essential factor for achieving both schedule and cost efficiency in renovation projects.

Renovation is appropriate when primary structural components such as foundations, columns, beams, and load-bearing frames still meet safety and load requirements. In such cases, localized strengthening or selective upgrades can enable the facility to meet new production demands without the need for complete reconstruction. Accurate structural assessment allows investors to maximize existing asset value and control costs effectively.

If the existing factory layout can be adjusted to suit production lines, renovation is a reasonable option. Reorganizing spaces, optimizing operational flows, and reconfiguring functional zones can significantly improve space utilization efficiency. This approach is particularly suitable for businesses that need process changes without major increases in building area.

When production capacity must be increased within a short timeframe, renovation offers a much faster implementation schedule than new construction. By leveraging existing infrastructure, construction duration is reduced, production disruption is minimized, and the factory can return to operation sooner—an important advantage for businesses with urgent expansion plans.

In many industrial zones, available land is scarce and rental costs are high. Renovating existing factories helps businesses avoid land acquisition costs and new investment procedures, making it a suitable solution for projects seeking to optimize investment under site constraints.

When a factory has deteriorated significantly, with major damage to foundations or load-bearing frames, renovation poses high safety risks and requires costly remediation. In such cases, building a new factory is a safer and more economically viable long-term solution.

Some modern production lines require high load capacities, increased working heights, or specialized spatial configurations. If the existing facility cannot meet these requirements even after strengthening, new construction offers greater flexibility in design and operation.

In certain cases, cumulative costs of strengthening, demolition, and system upgrades may approach the cost of building a new factory. When the economic benefits of renovation are no longer clear, new construction provides a more integrated, optimized, and manageable solution over the long term.

Effective renovation solutions begin with an accurate assessment of existing conditions and a clear understanding of the company’s investment objectives. Construction design at this stage focuses on evaluating load-bearing capacity, deterioration levels, infrastructure conditions, and actual usage needs. Based on this analysis, design solutions prioritize maximum reuse of valuable components while limiting intervention to what is necessary to achieve targeted investment efficiency. This approach prevents unnecessary renovation and ensures effective budget control.

In many projects, renovation is combined with capacity expansion or the addition of new functional areas. Integrated design for both renovation and expansion ensures consistency in structure, functionality, and technical systems. When all components are planned simultaneously within a comprehensive solution, technical conflicts are minimized and continuous factory operation is maintained. This integrated approach ensures long-term effectiveness rather than addressing only short-term needs.

Construction design plays a direct role in controlling renovation costs and schedules. Clear design documentation provides the basis for accurate cost estimates and feasible construction planning. Predefining intervention scopes, quantities, and construction methods helps minimize variations during execution. Additionally, well-planned designs support phased construction, reducing impacts on ongoing production activities.

An effective factory renovation solution extends beyond the design stage and requires close involvement throughout construction. Strong coordination between design and construction teams enables timely resolution of issues arising from complex existing conditions. When designs are flexibly updated to reflect site realities while maintaining technical principles, projects can stay on schedule, control costs, and achieve the quality objectives initially set by the investor.

Factory renovation is an effective investment solution in many cases where existing facilities still have exploitable potential. Compared to new construction, renovation helps reduce investment costs, shorten implementation time, and minimize production disruptions while still meeting upgraded functional, safety, and technical requirements. To make the right decision, investors must carefully assess structural conditions, technological needs, budgets, and schedules, and compare total costs and lifecycle efficiency.

Throughout this process, factory design plays a critical role in determining renovation feasibility, selecting optimal technical solutions, and controlling construction costs. A comprehensive and well-coordinated construction design is the essential foundation for achieving effective renovation outcomes, ensuring safety, and delivering sustainable long-term value for businesses.