The structural safety of a factory is a core factor that determines the building’s lifespan, production efficiency, and worker safety. A solid structure not only protects businesses against extreme weather conditions but also reduces risks of collapse, fire, or explosion ensuring stable and long-term operations. Conversely, if a factory is poorly designed or constructed without proper calculations, the initial investment may become a burden once accidents occur.

In practice, structural safety is influenced by many factors from geotechnical survey quality, factory design drawings, construction materials, and construction methods to usage loads and routine maintenance. Even a small mistake in any of these stages can lead to serious risks, production interruptions, and heavy losses in both assets and corporate reputation. Therefore, thorough consideration of these factors is mandatory in all factory design and construction projects.

With extensive experience in industrial projects nationwide, BIC works alongside businesses to ensure structural safety from the design stage through construction. BIC not only focuses on meeting technical and material standards but also emphasizes integrated solutions, enabling factories to operate efficiently today while remaining adaptable for future development.

Structural safety forms the foundation for stable and efficient production operations. A factory designed and built to standard can withstand loads from machinery, goods, and environmental impacts such as strong winds, heavy rain, or seismic vibrations. Conversely, weak structures may collapse or suffer partial failures at any time, causing severe damage to both people and assets.

First and foremost, a strong structure protects workers, the most valuable asset of any business. When a factory meets safety standards, employees can work with peace of mind, minimizing workplace accidents. This not only safeguards workers’ health but also helps maintain stable productivity.

Secondly, structural safety protects machinery and raw materials. Modern production lines worth billions of VND will not be affected by risks such as roof collapse, water leakage, or steel frame failure. As a result, production remains uninterrupted, orders are completed on schedule, and business credibility with clients and partners is maintained.

Finally, a structurally safe factory reflects a company’s long-term vision. Investing in robust design from the start reduces maintenance and repair costs while minimizing legal risks arising from non-compliance with construction regulations. This is a key factor for sustainable development and competitiveness in the market.

Geotechnical surveys are a critical first step in any project. Weak soil that is not properly examined can cause subsidence, cracks, or foundation tilting after a short period of use. Many factories have deteriorated within only a few years due to inadequate surveying or incomplete evaluations.

Additionally, design drawings serve as the “blueprint” of the entire building. If design calculations for load capacity, space distribution, or safety standards are inaccurate or overlooked, the factory structure may be overloaded, degrade quickly, and pose safety risks.

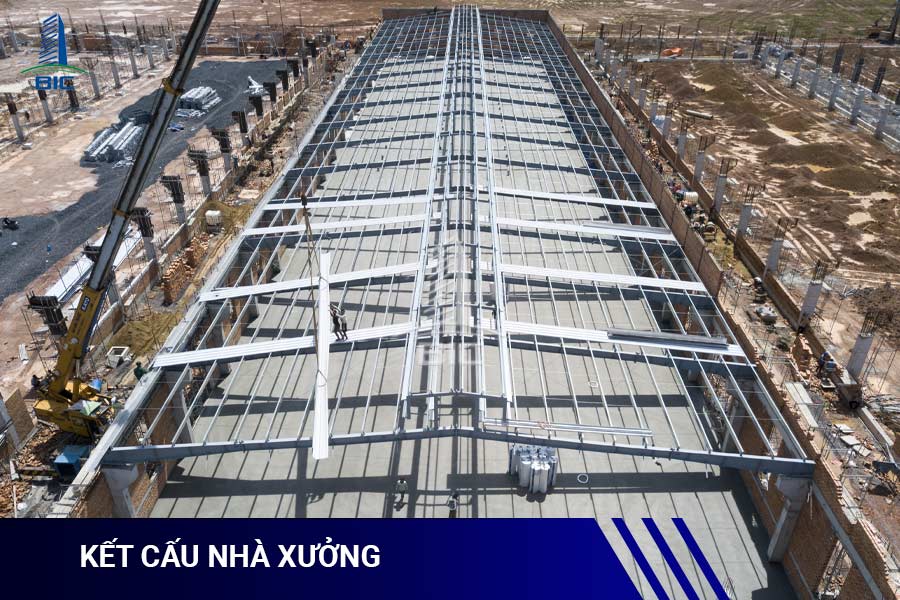

Materials directly determine a building’s lifespan. Low-quality steel is prone to rust, under-strength concrete cracks easily, and thin roofing sheets can be punctured or blown away by strong winds. The structural frame including columns, beams, purlins, and connections must ensure durability and load-bearing capacity. Using substandard materials may lower upfront costs but will result in much higher maintenance expenses later, and in the worst cases, could cause serious accidents and production downtime.

A quality design alone is not enough to ensure safety. Construction and supervision determine whether the design is executed to standard. Mistakes such as weak welds, loose bolts, or incorrectly mixed concrete can quickly degrade the building. This is why construction supervision plays such a vital role—ensuring that each stage is technically accurate and inspected before use. Even minor errors in construction can lead to serious long-term consequences.

Factory structures are designed based on expected loads. If businesses change functions or increase loads without recalculating, the entire structure may be compromised. For example, a factory originally designed for garment production may later be used as a warehouse for heavy materials, placing excessive stress on foundations and frames. This could result in deflected beams, cracked floors, or collapsed roofs common risks when businesses expand without consulting experts.

Industrial factories typically cover large areas and are directly exposed to the environment. In tropical, humid climates like Vietnam, heavy rainfall and high humidity accelerate steel corrosion, water infiltration, and structural weakening. In coastal areas, salt-laden air speeds up metal corrosion, reducing the strength of steel frames. Strong storms can also blow off roofs, threatening worker safety and assets. Therefore, factory design must account for local climate conditions and include appropriate protective measures.

Even the strongest structure requires regular inspection and maintenance. Small cracks, rusty welds, or warped purlins, if ignored, can develop into major safety hazards. Scheduled maintenance helps detect and address issues early, preventing collapse or operational risks. However, many businesses neglect maintenance to cut costs—only to face much higher expenses when accidents occur. This remains one of the most underestimated factors affecting structural durability.

To ensure structural stability, design must comply with national construction codes and technical standards, and, when necessary, international standards. Load calculations, structural solutions, and space planning should be based on geotechnical surveys, production scale, and future development goals. A well-planned design not only ensures stability but also provides flexibility for future expansion.

Selecting certified materials is essential for structural durability. Steel should be galvanized or coated for corrosion resistance, concrete must meet design strength, and roofing should use insulated, anti-corrosion sheets. In coastal or harsh climates, specialized anti-salt and anti-moisture materials are required. Investing in high-quality materials from the start reduces long-term maintenance costs and extends the factory’s lifespan.

Even with proper design and quality materials, safety can be compromised if construction is not carried out correctly. Construction must be supervised by technical experts to ensure that structural steel installation, welding, concrete pouring, and roofing meet standards. Close supervision helps identify mistakes early, prevents future risks, and guarantees final handover quality.

Factories must operate within the load limits set during the design stage. If businesses need to change functions, add machinery, or increase storage capacity, structural recalculations and reinforcements are required. Efficient space planning ensures smooth production, prevents overloading, and extends structural lifespan.

Maintenance acts as a protective shield against natural wear over time. Businesses should establish regular inspection plans for foundations, steel frames, roofing, purlins, and drainage systems. Routine technical checks detect early signs of deterioration such as cracks or rusted welds allowing timely intervention. This not only ensures safety but also reduces costly future repairs.

The structural safety of factories largely depends on the expertise of design construction firms. A professional partner helps businesses manage safety factors from the start, covering geotechnical surveys, load calculations, material selection, and functional layouts all with technical precision and compliance with standards.

In addition to detailed drawings, professional firms also provide optimized solutions that integrate structure, functionality, and technical systems. They oversee construction to ensure compliance, minimize errors, and mitigate risks.

Moreover, a reputable partner continues to support businesses during operation by assisting with inspections and scheduled maintenance. This ensures long-term structural safety, reduces repair costs, and maintains stable production.

The structural safety of factories not only determines building lifespan but also directly impacts production efficiency and worker safety. From surveying, design, and material selection to construction and maintenance, every factor plays a critical role in ensuring durability and long-term stability.

To achieve this, partnering with a professional design and construction firm is the most effective solution. With experienced engineers and a proven track record in industrial projects, BIC is committed to helping businesses design and build factories that are safe, modern, and efficient. This provides a solid foundation for protecting assets, maintaining stable production, and strengthening business reputation in the market.