In mechanical factories, where heavy-duty machinery operates continuously at high loads and speeds, vibration is inevitable. However, without effective vibration control measures, these mechanical oscillations can seriously impact machining accuracy, equipment lifespan, worker safety, and the overall quality of the working environment.

That’s why designing anti-vibration flooring has become a critical component in the construction of modern mechanical workshops. Depending on the production characteristics and types of machinery in use, businesses must choose appropriate technical flooring solutions to ensure stable operations and optimize long-term investment efficiency.

In this article, BIC introduces common anti-vibration flooring solutions, relevant design standards, and suggestions tailored to different types of mechanical workshop models.

Anti-vibration flooring is a specialized type of technical floor designed to limit and control vibrations generated during the operation of industrial machinery and equipment. These floors typically combine a strong substructure with damping layers such as engineered rubber, resilient underlayments, vibration-isolating mats, or floating floor systems. Depending on production requirements, floors can be constructed as either monolithic slabs or isolated sections to reduce vibration transmission to surrounding areas.

The implementation of anti-vibration flooring not only meets technical demands in mechanical production but also enhances the overall operational efficiency of the facility.

In mechanical workshops, vibrations often stem from CNC machines, lathes, stamping machines, or the movement of forklifts. Without proper control, these vibrations can cause several critical issues:

- Machining inaccuracies: Floor vibrations destabilize machines, reducing cutting and measurement precision.

- Shortened equipment lifespan: Repetitive vibrations strain joints, bearings, and machine frames, leading to frequent failures and maintenance needs.

- Health and productivity concerns: Constant vibration creates discomfort, fatigue, and decreased worker productivity.

- Operational risks: Vibrations may shift machinery out of position, increasing the risk of workplace accidents.

Thus, investing in anti-vibration flooring is a strategic move in modern factory design, helping businesses improve production quality and protect long-term assets.

Depending on the factory’s size, production type, and machinery, investors can choose among several flooring technologies to optimize vibration control, minimize risks, and ensure stable operations. Below are widely adopted solutions:

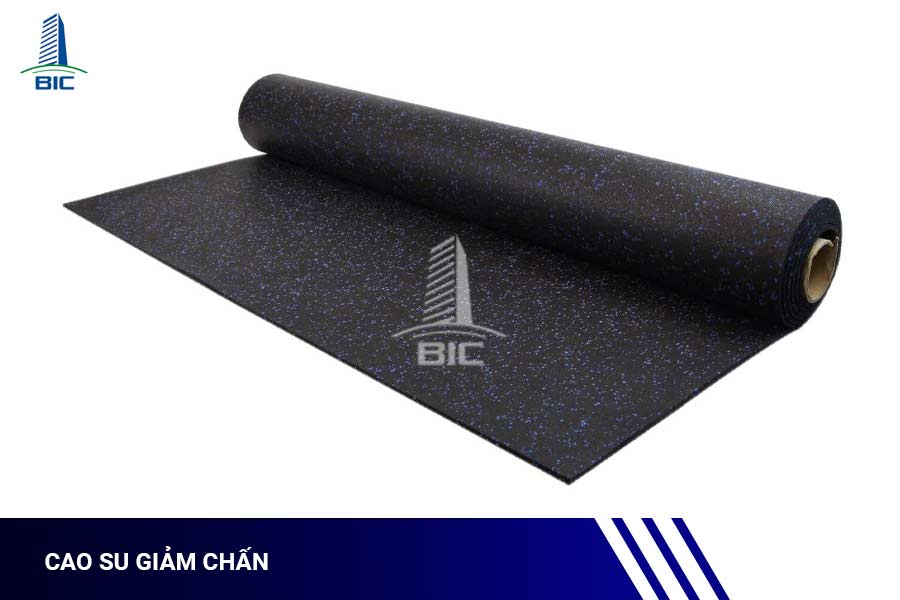

This is a simple and cost-effective solution suitable for small workshops, retrofitted spaces, or areas with light to medium machinery. Materials such as engineered rubber pads, elastic cushions, or high-density foam are laid under the floor or machine base to reduce vibration transmission.

- Pros: Quick installation, no changes needed to existing floor structure.

- Cons: Moderate vibration reduction only; not suitable for heavy loads or high-precision machinery.

Best suited for: Small-scale workshops or renovation projects.

A specialized solution for heavy-duty zones experiencing strong vibrations. This system includes reinforced concrete slabs with carefully engineered foundations, combined with damping layers like technical foam, industrial rubber membranes, or vibration-isolating underlays beneath the finished surface.

- Pros: High durability; excellent horizontal vibration control.

- Ideal for: Heavy mechanical workshops, areas with presses, stamping machines, etc.

Commonly chosen in comprehensive vibration-resistant designs from the beginning.

This approach creates a separate floor layer completely isolated from the main building structure using elastic pads or resilient framing systems. It prevents vibration from spreading from machines to the building structure and vice versa.

- Pros: Superior vibration control; ideal for high-precision environments like CNC shops, metrology rooms, or cleanrooms.

- Cons: High cost; requires specialized design and installation.

Ideal for: High-tech modern factory designs prioritizing equipment stability.

A flexible solution commonly used for individual machines with high vibration levels. Each machine is mounted on a dedicated concrete block (isolated foundation) integrated with rubber pads or specialized damping systems.

- Pros: Isolates machine-specific vibration; easy to maintain and replace individually.

- Ideal for: Areas with lathes, drills, milling machines, etc.

- Effective when combined with existing mechanical flooring systems.

Each factory should select a vibration-control solution tailored to its vibration intensity, equipment type, and investment goals to ensure structural durability, production efficiency, and operational safety.

An effective vibration-resistant floor system relies not only on materials or structural choices but also on strict adherence to technical design standards especially critical in mechanical facilities where accuracy and safety are paramount.

Floor designs should follow international vibration criteria, such as:

- ISO 2631: Evaluation of human exposure to whole-body mechanical vibration.

- VDI 2056 (Germany): Limits on vibration levels for precision equipment foundations.

- JIS B 0907 (Japan): Technical standards for precision mechanical engineering.

These standards help quantify acceptable vibration levels by equipment type and workspace.

Materials must be resilient, durable, and capable of absorbing vibrations:

- Engineered rubber, polyurethane, or specialized damping foam.

- Reinforced concrete slabs should be structurally calculated based on machine load and vibration frequency, with necessary footing or foundation reinforcements.

Designs must prevent floor settlement, cracking, or resonance over time.

- Floor stiffness should be balanced to prevent reverse vibration feedback.

- Optimize vibration isolation between zones especially between heavy machinery, inspection areas, and forklift pathways.

- Allow easy access and removal of damping layers for maintenance.

Vibration-resistant flooring solutions must be incorporated into the overall factory design, ensuring coordination with:

- Foundation and subfloor systems.

- Machinery layout.

- Supporting technical systems (electrical, piping, drainage, etc.).

Tight coordination between structural, MEP (mechanical, electrical, plumbing), and mechanical floor designers is essential for long-term performance.

Anti-vibration flooring is not just a technical component, it’s a foundational factor that determines the production efficiency, machinery lifespan, and safety level in modern mechanical workshops. To ensure the economic, technical, and sustainable viability of vibration-resistant floor systems, businesses should partner with experienced construction and engineering firms familiar with the mechanical sector and international vibration standards.

Proper early-stage consultation doesn’t just optimize investment, it ensures safe, stable, and long-lasting operations.