In the field of factory construction design, choosing the right building materials not only affects the durability and safety of the structure but also determines investment efficiency and long-term operating costs. Every material from structural frames, enclosure walls to roofing and factory flooring plays a distinct role in ensuring functional performance, scalability, and adaptability to specific production environments.

However, not every investor fully understands which materials to choose in order to meet technical standards while optimizing costs. In a market increasingly focused on green, sustainable, and energy-efficient solutions, understanding and applying the right materials will be the key to creating a competitive edge for businesses.

In this article, BIC will help you systematize the essential selection criteria, provide in-depth analysis of commonly used materials in industrial factory construction, and suggest optimal options tailored to different types of production, helping investors make the most accurate and effective decisions.

In factory design, selecting building materials is not just a technical decision, but a long-term investment strategy that impacts the quality of the facility, operational efficiency, and overall costs. A correct decision from the outset can save enterprises hundreds of millions of VND annually, while a poor choice can lead to numerous operational risks.

Building materials play a core role in ensuring structural stability, load-bearing capacity, and long-term reliability. Factories are typically subject to harsh operating environments including vibrations from machinery, heavy loads, high temperatures, or corrosive chemicals. Using unsuitable materials can cause cracking, ground subsidence, or premature deterioration compromising safety and increasing maintenance costs.

Materials such as pre-engineered steel, insulated panels, and lightweight roofing allow for faster construction and facilitate easy dismantling, renovation, or expansion when needed. In contrast, traditional materials like concrete, brick walls, or clay tiles, while durable, require longer construction time and are harder to modify in the future especially when the production model evolves.

The cost of a factory goes beyond initial construction; it extends throughout its lifecycle. Choosing the right materials reduces energy consumption (thanks to good insulation), lowers maintenance labor, and increases building longevity.

For example, using PU-insulated metal roofs can reduce interior temperatures by 5–7°C compared to regular roofing, cutting down on cooling costs.

Industries such as food, pharmaceuticals, and chemicals must comply with strict standards like GMP, ISO 9001, ISO 14001, and fire protection codes. Choosing the wrong materials (e.g., flammable panels, non-chemical-resistant flooring) may lead to failed approvals or inspections, halting operations and causing costly adjustments.

Choosing materials for a factory should not be based solely on price or mechanical strength. Investors need to evaluate various technical and operational criteria aligned with their long-term development goals. Here are five critical factors to consider:

Factories house heavy machinery and operate continuously, requiring materials that resist cracking, subsidence, or deformation.

- Pre-engineered steel is favored for its high load capacity and resilience to mechanical stress.

- High-grade reinforced concrete ensures floor stability, even under forklifts or heavy containers.

Industrial environments often involve heat, noise, fire hazards, or chemical exposure. Materials must:

- Provide effective insulation to reduce reliance on cooling systems.

- Prevent fire spread to meet safety standards.

- Resist corrosion especially in food, chemical, or seafood industries.

The ideal material is not necessarily the most expensive, but the one that offers the best total cost-effectiveness.

- Consider material + installation + operation + maintenance costs.

- Use materials that reduce energy consumption (e.g., daylighting roofs, insulated panels).

- Avoid short-term savings that result in long-term expenses.

Modern manufacturing demands flexibility in both building and operations:

- Materials like modular panels and steel frames shorten construction time and allow future changes.

- Maintenance or replacements can be made without disrupting entire systems.

In factories combined with offices or showrooms, materials must also meet aesthetic standards:

- Glass-aluminum facades, daylight roofs, and metal cladding create a modern, professional appearance.

- Coordinated colors and design support brand recognition.

Each factory component from foundation and structure to roof, walls, and floors requires suitable materials to ensure performance and cost-effectiveness.

Pre-engineered Steel:

- High strength, lightweight, easy to assemble.

- Prefabricated off-site and quickly installed.

- Ideal for most industries: mechanical, electronics, logistics, textiles.

Reinforced Concrete:

- Essential for foundations, tanks, or special zones (chemical storage, fireproof areas).

- Strong, fire-resistant but slower to build and harder to modify.

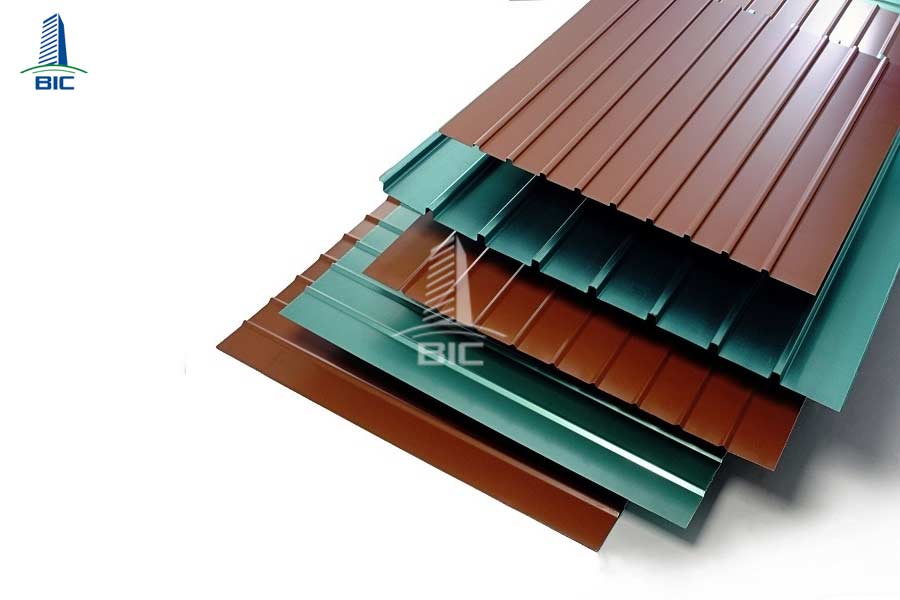

PU, EPS, or Rockwool Insulated Metal Sheets:

- Three-layer construction for heat and sound insulation.

- Standard for tropical climates like Vietnam.

- Rockwool core enhances fire resistance.

Non-insulated Galvanized/Cold Steel Sheets:

- Cheaper but less effective for heat and sound.

- Suitable for temporary or low-spec warehouses

Polycarbonate Daylight Panels:

- Used intermittently with roofing sheets for natural lighting.

- Must be strategically placed to avoid heat or glare.

PU, EPS, or Rockwool Panels:

- Fast installation, clean finish, strong insulation and fireproof properties.

- Ideal for GMP/ISO plants, cold storage, food processing areas.

Traditional Bricks or Concrete Blocks:

- Sturdy, impact-resistant, good soundproofing.

- Slower to build and harder to alter later.

- Suitable for high-security or segmented areas.

High-grade Reinforced Concrete:

- Supports heavy equipment and frequent vehicle traffic.

- Requires proper thickness, steel mesh, and drainage design.

Epoxy Coating:

- Enhances aesthetics, slip resistance, easy cleaning, and chemical resistance.

- Standard for food, pharma, and cleanroom areas.

Anti-slip or Acid-resistant Tiles:

- Used in chemical zones, wastewater plants, washrooms, or kitchens.

- Highly durable, but must be installed correctly.

Industrial Roller Shutters:

- Made of steel or aluminum; automatic options for logistics zones.

- Secure and efficient for forklift and truck access.

Aluminum Glass or Fire-resistant Doors:

- Used in offices, corridors, and emergency exits.

- Glass adds openness and modernity.

Panel or Moisture-resistant Drywall Partitions:

- Divide office, admin, and production areas.

- Easily reconfigured as needed.

|

Factory Type |

Production Characteristics |

Recommended Materials |

|

Mechanical/Metalwork |

Heavy vibration, high loads, dusty & noisy |

Pre-engineered steel frame, PU roof sheets, EPS panels or impact-resistant brick walls, high-grade epoxy floors, steel roller doors |

|

Food/Pharmaceutical (GMP) |

Clean, antibacterial environment, strict zoning |

PU or rockwool insulated panels for walls/ceilings, waterproof epoxy floors, stainless steel/glass safety doors, natural ventilated PU roofing |

|

Logistics/Warehouses |

Maximize storage, forklift use |

Large-span steel frames, PU roofing with skylights, EPS panels, reinforced concrete floors with hardener or epoxy, high-speed or large sliding doors |

|

Chemical/Flammable Materials |

Corrosive, fire hazards, strict fire safety |

Rockwool fire-resistant panels, powder-coated steel, acid-proof tiles or chemical-resistant coatings, fire doors, safety partitions |

|

Electronics/Cleanrooms |

Dust/humidity control, anti-static |

PU panels with anti-dust film, ESD epoxy flooring, sealed aluminum/glass doors, HVAC-compliant PU roofing |

|

Factory with Office/Showroom |

High aesthetics, production-office split |

Combined materials: steel frame, aluminum/glass façade, moisture-resistant drywall, tempered glass, aluminum ceiling, PU + polycarbonate roof |

Note:

- All materials must comply with applicable regulations: QCVN, TCVN, Fire Code, ISO, GMP, etc.

- For factories in industrial parks, listed materials must be registered in initial submission to avoid delays.

Do not copy other models blindly; base your decision on:

- Product characteristics (temperature, humidity, dust, chemicals, etc.)

- Equipment load and usage frequency

- Industry standards (fire safety, GMP, ISO, LEED...)

Ensure all material choices are reflected in:

- Architectural, structural, electrical, plumbing drawings

- Legal documents for construction/fire safety approval

- Machinery and layout planning

Avoid cheap materials that lead to:

- Higher long-term operating costs

- Compliance failures

- Poor corporate image if partners/clients visit

A seasoned firm will:

- Propose suitable materials tailored to your needs

- Ensure material compatibility and aesthetic quality

- Flag legal/operational risks due to subpar materials

Choosing the right materials does not just determine construction quality, but directly affects production efficiency, operating costs, and facility longevity. A smart decision during the design phase can save a company from major risks and maximize return on investment.

If you’re planning to build a factory and need expert advice on materials that meet technical, financial, and regulatory standards, contact the BIC team today.

BIC – Trusted factory design and construction experts with industry-standard knowledge, committed to partnering with your business from the first blueprint to project completion. Contact us now for a free consultation and detailed quotation!