Designing a factory is not only the initial step in the construction process but also a decisive factor in the long-term operational efficiency of a business. A proper design helps optimize functionality, save construction costs, and ensure worker safety. When the process is carried out correctly, the factory not only meets current production needs but also allows for easy expansion in the future.

To achieve this, adhering to a structured design process is essential. This process includes stages from site survey, preliminary planning, detailed design, to appraisal and handover of documents. Each step plays a crucial role in ensuring that the project fits production requirements, complies with technical standards, and delivers optimal economic value.

In the context of increasingly diverse demands for factory construction, understanding the necessary steps in design will help businesses be more proactive in planning and cost control. At the same time, it serves as a foundation for selecting modern, eco-friendly design solutions aligned with sustainable development goals. Let’s walk through the essential process for designing an efficient factory with BIC in the following article.

A scientific and rigorous design process is the foundation for businesses to own a facility that is efficient, safe, and sustainable. Following the process properly brings many important benefits:

A proper design process allows accurate prediction of material quantities, labor, and construction time. This helps businesses avoid unplanned expenses while shortening construction schedules. Clear drawings also make construction easier for contractors, minimizing errors and repair costs.

A rational factory design ensures efficient layout, smooth production flow, and optimized storage space. When functionality is properly calculated from the start, businesses can operate more effectively, reduce material handling time, and increase labor productivity.

A standard design always strictly follows regulations on structural stability, fire protection, electrical and plumbing systems, and environmental safety. This not only protects workers but also helps businesses avoid legal risks, ensuring stable and sustainable production.

An efficient factory cannot be created from impulsive decisions but must go through a systematic design process. Below are the key steps that help businesses achieve an optimal facility in terms of functionality, cost, and quality:

Surveying is the first and most important step in the factory design process. The business needs to determine the land area, terrain characteristics, soil foundation, and surrounding infrastructure. In addition, analyzing functional needs such as warehouses, production areas, offices, or cleanrooms helps shape actual requirements. This stage also allows prediction of production capacity and future expansion potential.

After the survey, architects and engineers develop a preliminary design proposal. The master layout is scientifically arranged to optimize production flow and internal traffic. This plan not only provides a clear visualization of the future facility but also enables an initial cost estimate, helping investors make informed decisions.

This is the critical stage of turning ideas into detailed drawings. The architectural design must align with production functions, aesthetics, and practicality. The structure is calculated to ensure durability and safety throughout use. At the same time, technical systems such as electricity, water, ventilation, and fire protection are implemented to meet strict operational standards.

A detailed cost estimate is prepared to determine expenses for each work item. This forms the basis for businesses to evaluate the feasibility of the design, balance budgets, and optimize resources. At this step, design options are often compared and analyzed to select the most suitable one.

The design must be checked against technical standards and legal regulations such as TCVN and QCVN. Appraisal ensures compliance with requirements on structure, workplace safety, environment, and fire protection. Once completed, the documents are approved and serve as the basis for applying for a construction permit.

The final stage involves handing over all detailed design documents to the investor and contractor. During construction, the design team may provide technical support to ensure the actual project aligns with the drawings. This helps minimize errors, shorten construction time, and improve project quality.

A proper design not only follows the basic process but also pays attention to practical factors. These details make the difference between a standard facility and an inefficient one.

Location is always a decisive factor. A factory located near highways, seaports, or airports helps businesses significantly reduce material transportation and product distribution costs. Conversely, choosing land far from infrastructure can lead to higher logistics costs and difficulties in attracting labor. Building in industrial zones with existing infrastructure such as electricity, water, wastewater treatment, or fire protection not only reduces initial investment costs but also simplifies permitting and operations.

A modern factory must be both durable and energy-efficient. By utilizing natural light and wind, businesses can cut monthly electricity costs by significant percentages. Common solutions include skylights, louvered windows, roof light panels, and wind catchers. Using thermal insulation materials for roofs and walls also helps maintain a cooler indoor environment, reducing reliance on artificial cooling. For large-scale projects, rooftop solar systems can also be considered to secure clean energy sources.

Production needs often change over time. If a factory is designed too rigidly, future expansion may become costly and difficult. Therefore, right from the design stage, investors should reserve additional land, design logical internal traffic, and choose flexible structural systems. Technical systems such as electricity, water, and drainage should also be designed with extra capacity to meet future expansions.

Workplace safety is vital for any factory. No matter how modern a facility is, it poses risks if safety is not ensured. From the design stage, attention must be given to automatic fire protection systems, clear emergency exits, and dedicated firewater tanks. Wastewater and exhaust systems must also meet environmental standards to avoid fines or production interruptions. Strict compliance with construction codes, load standards, and structural safety ensures worker protection and long facility lifespan.

The green factory trend is increasingly important, not only for sustainable development but also for building a responsible business image. Reasonable allocation of green space, use of recycled materials, and reduction of CO₂ emissions help businesses achieve international certifications such as LEED, EDGE, or LOTUS. At the same time, applying automation and smart management systems (BMS) enables businesses to effectively control lighting, air conditioning, and power consumption, optimizing long-term operating costs.

Self-managing factory design or relying on basic drawings often involves risks from unexpected costs to facilities not meeting actual needs. That is why many businesses choose to work with professional design firms to ensure efficiency and safety.

Professional firms go beyond drafting drawings by accompanying investors through site surveys, needs analysis, and optimal planning. They have experience in geotechnical assessment, layout planning, and structural solutions. As a result, the design meets production requirements while optimizing costs.

A proper design helps construction proceed quickly, minimizing costly errors or revisions. Professional design firms have clear workflows and close coordination among architects, structural engineers, and MEP engineers. This ensures not only high-quality facilities but also on-time completion, allowing businesses to put factories into operation sooner.

Factories are special structures that must comply with many regulations on safety, environment, and fire protection. Design flaws can cause permit issues or fines. Reputable design firms always update and apply the correct TCVN, QCVN, and legal requirements, ensuring absolute compliance and safety.

A properly designed factory provides value far beyond initial costs. It improves production efficiency, reduces operating expenses, and strengthens a professional corporate image. For export-oriented businesses, owning an internationally certified factory also creates competitive advantages in signing contracts and expanding markets.

Factory design is the foundational step that determines production efficiency, workplace safety, and long-term growth potential of a business. A proper design process, combined with professional support, helps investors optimize costs, shorten construction time, and ensure compliance with technical standards.

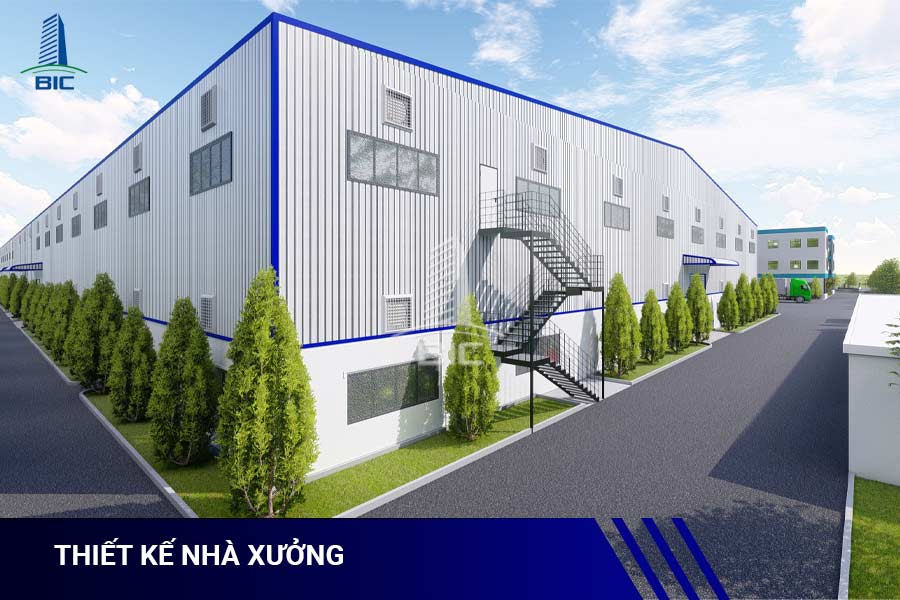

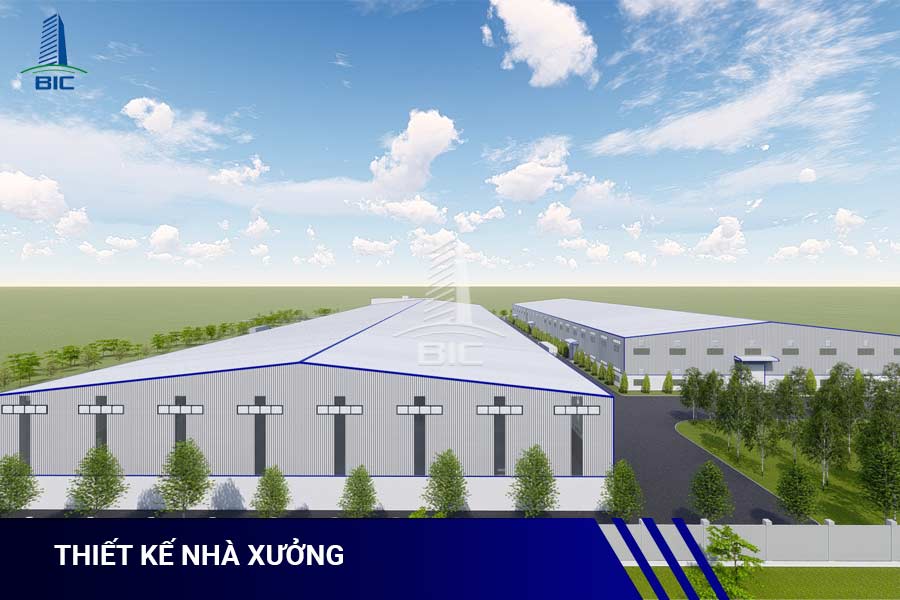

At BIC, each factory design is not just a technical drawing but a comprehensive solution aligned with each business’s practical needs. With experience in industrial construction design, BIC is committed to delivering sustainable projects that optimize costs and support long-term development goals.

Investing in design with BIC is not just an initial expense but a strategy for sustainable benefits. Businesses with efficiently designed factories will gain significant advantages in operations, cost savings, and market reputation.