In the field of modern industry, production efficiency does not only depend on technology or human resources but is also closely tied to the quality of factory design. A scientifically calculated design will help businesses optimize production flow, minimize operating costs, and ensure safety standards. On the contrary, mistakes from the construction design stage can lead to unsynchronized production lines, increased remedial costs, and reduced productivity.

In fact, many businesses, when investing in factories, have begun paying greater attention to integrating the production process right from the drawing stage. This not only ensures that the construction meets functional requirements but also creates a foundation for the application of automation technology, smart warehouse management, and green standards in production. Therefore, factory design today is no longer limited to simply providing a place for production, but has become a strategic solution that determines competitiveness and long-term development.

A factory design not only determines the appearance of the project but also directly impacts all production activities that follow. Its role is clearly reflected in the following aspects:

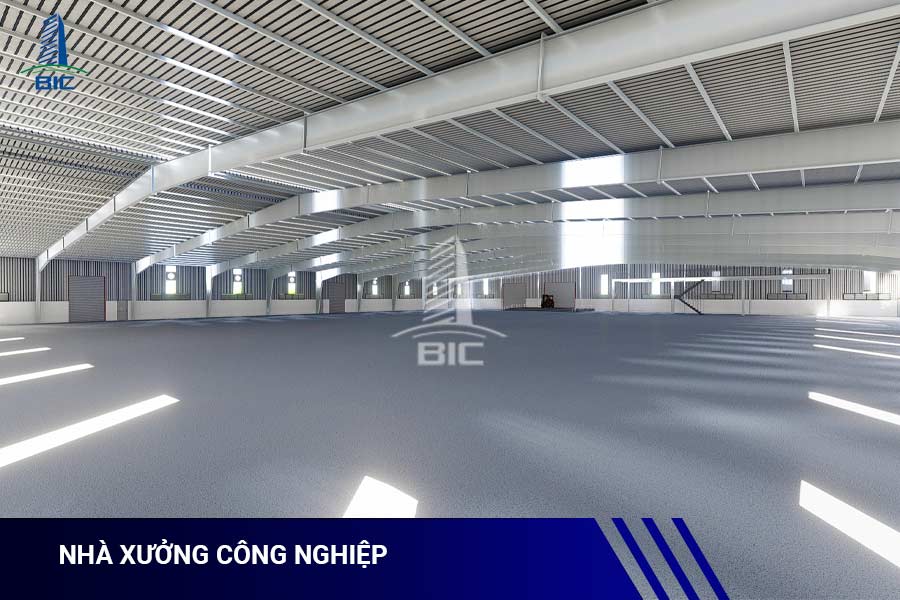

A rational spatial layout helps shorten the transportation time of materials, reduce waste in operations, and limit overlapping between processes. Arranging production lines according to a logical flow also allows staff to work more effectively, minimizing errors during operation.

A scientific design eliminates the risk of bottlenecks that cause process congestion, a common reason for production interruptions. When sections are arranged logically, production runs smoothly, increasing productivity and stabilizing product quality.

Factories must not only serve production but also comply with regulations on fire prevention and fighting, ISO standards, or GMP depending on the industry. Incorporating these factors from the design stage helps businesses save on adjustment costs and avoid legal risks during operation.

Factory design is not simply about building a structure but about establishing a foundation for efficient operations for many years. The link between design and operation is shown through forecasting future expansion needs, integrating new production technologies, and creating a safe and sustainable working environment for employees.

To truly optimize factory design, it is necessary first to thoroughly analyze the business’s production process. Each industry has its own characteristics, from the supply chain of raw materials to finished products, and these characteristics determine how production spaces are organized.

A general production process usually includes: receiving raw materials, pre-processing or machining, assembly, quality control, packaging, and warehouse storage. Without careful design planning, the movement of materials between these stages can cause disruptions, increase internal logistics costs, and reduce efficiency.

Factory design must accurately reflect production characteristics and ensure that layouts align with process stages. For example:

- In the food industry, production flow must be one-way to ensure hygiene and safety.

- In textiles, spacious areas are required for continuous sewing lines, avoiding interruptions in product flow.

- In logistics, warehouses must connect smoothly with loading/unloading areas and transportation systems.

Besides meeting current needs, the design must also account for potential expansion or process changes in the future. This is essential for businesses to quickly adapt to market demands and new production technologies.

To build a factory that both meets production needs and ensures long-term operational efficiency, adopting optimal design solutions is crucial. These solutions not only save costs but also enhance competitiveness in the market.

Layout planning based on production flow (linear flow, U-shape layout, or modular layout) ensures smooth movement of raw materials and products from input to output. Rational arrangement reduces transport time and prevents congestion within production lines.

BIM (Building Information Modeling) and 3D simulation tools allow businesses to visualize the entire production space before construction. This helps detect layout conflicts early, reducing correction costs and improving accuracy in implementation.

A major trend in construction design today is the application of green standards such as LEED, LOTUS, or Net Zero orientation. Green factories use eco-friendly materials, harness natural lighting, ventilation systems, and solar solutions, helping businesses cut operating costs and enhance brand image.

Integrating automation systems and IoT sensors from the design stage allows businesses to build a “smart factory” model. This not only enables real-time production monitoring but also supports data analysis, predictive maintenance, and improved product quality.

The implementation of industrial projects in Vietnam shows that factory design must go hand in hand with real production and operational environments. Many businesses have succeeded by focusing on optimization right from the design stage, while others have paid a high price for initial mistakes.

In food processing factories, one-way production flow design has enabled businesses to meet food safety control requirements while saving significant inspection and operation costs. Conversely, some mechanical projects that failed to plan for expansion had to dismantle and renovate after only a few years, doubling investment costs.

Some factories with poorly planned layouts forced materials to move in circles across multiple areas. This increased internal transportation costs, wasted manpower, and prolonged production time. Additionally, failure to integrate fire protection systems or warehouses from the beginning could result in legal violations, forcing businesses to suspend operations for remediation.

- With a hot and humid climate, ventilation and insulation are essential to protect worker health and extend building lifespan.

- Increasingly strict regulations (Decree 35/2022 on Industrial Parks, ISO and GMP standards) require factories to meet compliance from the design stage to avoid costly adjustments.

- The trend of developing logistics industrial zones near seaports and airports requires factories to have flexible infrastructure, ready for global supply chains.

These practical experiences confirm that a successful factory design must not only meet current needs but also anticipate future changes, enabling businesses to operate efficiently and sustainably.

Besides layout planning and optimizing production flow, a modern factory design must also account for supplementary factors that support long-term growth.

Markets are constantly changing, and production demand can grow rapidly or shift with business strategies. Factory design must provide flexible spaces that can be easily upgraded or expanded without disrupting ongoing operations.

A sustainably designed factory reduces maintenance costs, limits structural wear, and extends the building’s lifespan. Using eco-friendly materials, natural lighting, and ventilation systems also contributes significantly to lower operating costs.

An optimized factory should not only include production areas but also integrate supporting spaces such as management offices, QC/QA rooms, R&D areas, meeting rooms, and employee facilities. This ensures synchronized operations, enhances management efficiency, and boosts employee morale.

In today’s diverse industrial context, an intelligently designed factory can be easily adapted to various types of production from cold storage and food processing to logistics centers or mechanical assembly workshops. This adaptability helps businesses maximize asset value and reduce risks when shifting industries.

A scientifically designed factory, aligned with production processes, brings businesses many outstanding benefits. These are not just short-term advantages but also foundations for sustainable growth.

With optimized material flow and rational production line layout, businesses can shorten production time and reduce idle waiting between stages. This directly boosts labor productivity and order fulfillment capability.

Optimal design saves electricity, internal transport, and manpower costs. Moreover, integrating fire protection systems, wastewater treatment, and workplace safety from the outset prevents costly renovations and incident handling.

When production processes run continuously and stably, product quality becomes more consistent. This helps businesses build trust with customers, especially in industries requiring high standards such as food, pharmaceuticals, and electronics.

Factories designed with flexibility allow businesses to easily expand scale or adjust production lines in response to market changes. This is a critical advantage for maintaining competitiveness in an ever-changing industrial environment.

To own a factory that optimizes both production processes and long-term value, choosing a reputable design and construction unit is key. A capable partner not only delivers precise drawings but also accompanies businesses throughout implementation and operation.

- Experience and expertise: Proven track record with multi-industry factory projects, with the ability to analyze and apply suitable solutions.

- Legal compliance knowledge: Familiar with fire safety, environmental, GMP, and ISO regulations, ensuring projects meet legal requirements from the start.

- Use of modern technology: BIM, 3D simulation, green design—ensuring cost savings and eco-friendliness.

- Comprehensive services: From surveying, design, and construction to handover and maintenance, providing businesses with peace of mind on schedule and quality.

Businesses receive design solutions that are not only technically sound but also operationally effective. Every production stage and functional area is carefully calculated to serve long-term development goals. Furthermore, collaborating with a reliable partner helps businesses save time, optimize costs, and avoid risks during implementation.

A reputable design and construction unit does not merely hand over a building but delivers a comprehensive solution for business growth. This foundation enhances competitiveness, supports production expansion, and strengthens market position.

Factory design is not just the starting point of a production facility but also the foundation that determines operational efficiency for many years to come. When production processes are optimized right from the design stage, businesses benefit from higher productivity, lower costs, and greater adaptability to market changes. A scientific design that complies with legal standards and aligns with real production needs is the “key” to enhancing competitiveness and ensuring sustainable development.

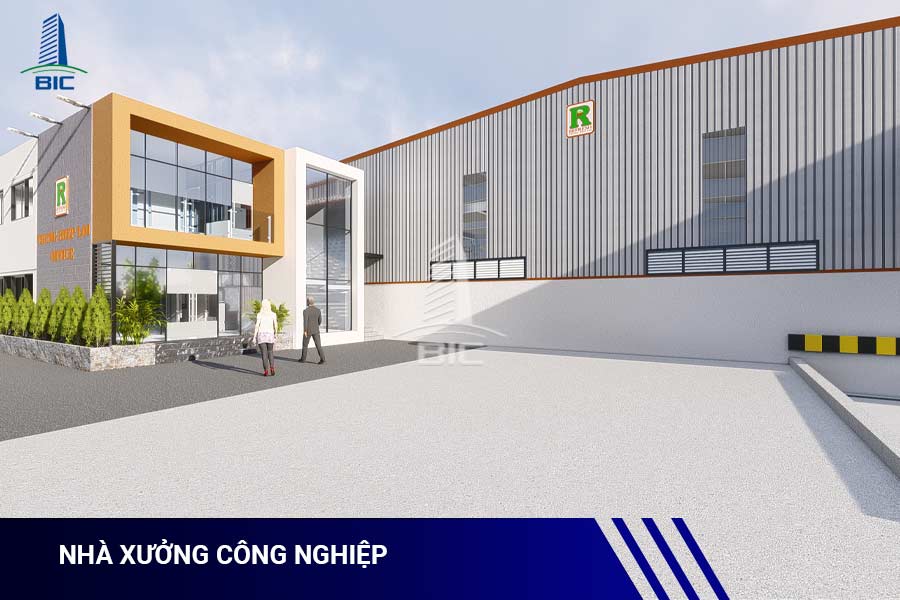

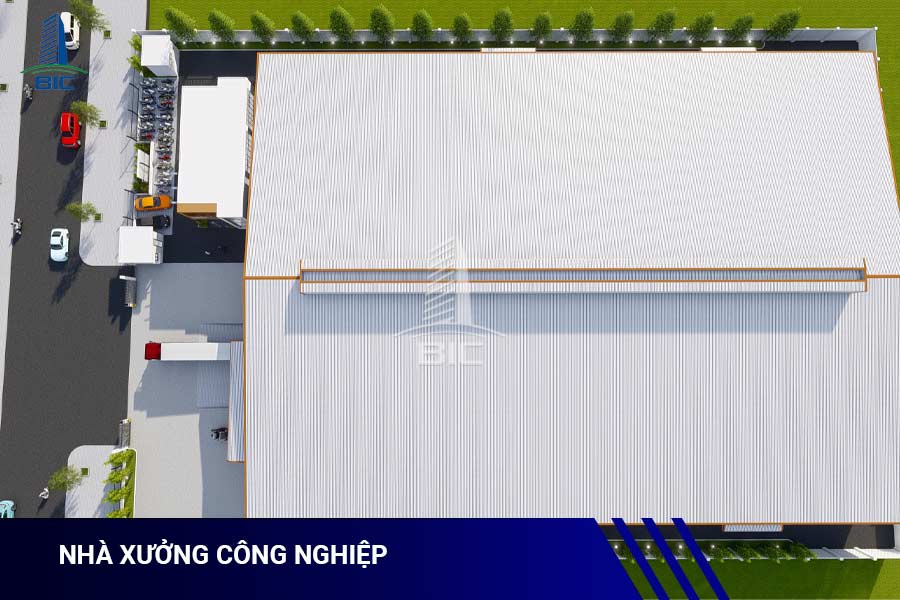

If your business is looking for an effective factory design and construction solution, start today with a reputable partner. Contact BIC for consultation, surveys, and detailed quotations, turning your vision into an optimized project for the future.