Industrial factories play a central role in production activities, serving as the hub for machinery, operational lines, and the workforce. A standard factory not only meets current usage needs but also creates favorable conditions for future business expansion. Therefore, the process of designing and constructing factories must be carried out methodically, in compliance with technical standards and legal regulations.

Among these, the structural system of an industrial factory is considered the backbone of the entire building. It determines durability, load-bearing capacity, safety, and flexibility in operation and renovation. Understanding the characteristics, components, and design requirements of factory structures helps investors choose optimal solutions, ensuring long-term efficiency. In this article, BIC will provide a detailed look into industrial factory structures before starting a construction project.

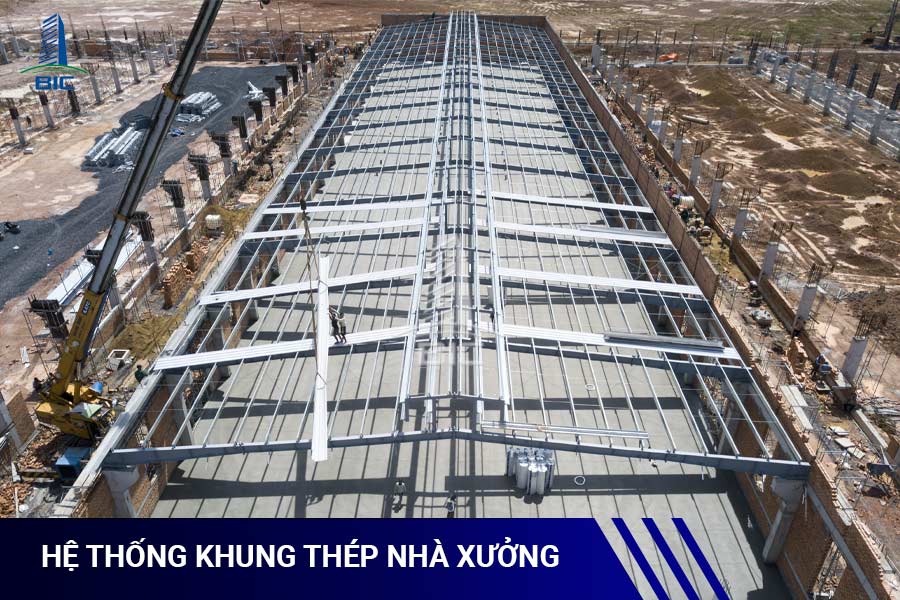

Today, most industrial factories are built using pre-engineered steel frame systems. This modern solution replaces traditional reinforced concrete methods, offering outstanding advantages in both technical performance and cost.

- Fast construction timeline: Steel components are prefabricated in factories according to detailed design drawings and then transported to the site for assembly, significantly shortening project timelines.

- Superior load-bearing capacity: Steel has high tensile strength and ductility, making it suitable for large-scale projects requiring wide spans.

- High flexibility: Steel frames are easy to assemble, expand, or renovate, creating favorable conditions when businesses need to upgrade or change factory functions.

Thanks to these advantages, steel structures are increasingly applied in industrial factory construction, becoming the optimal choice for investors.

When factory design, the following technical parameters must be calculated precisely to ensure durability and efficiency:

- Span: The horizontal distance between two boundary columns, determining production space width.

- Factory height: Directly affects ventilation and the installation of machinery and cranes.

- Roof slope: Usually ranges from 10% to 30%, ensuring quick rainwater drainage and preventing leaks.

- Foundation and roof load: Must be calculated based on production characteristics, such as machinery weight, vehicles, ceiling systems, roofing sheets, wind, and storms.

Accurately determining these parameters ensures that industrial factory construction is safe, cost-effective, and suitable for long-term production.

A standard industrial factory typically consists of multiple structural elements closely connected. Each plays an important role in ensuring load-bearing capacity, durability, and operational convenience. When designing and constructing, investors must pay special attention to the following components:

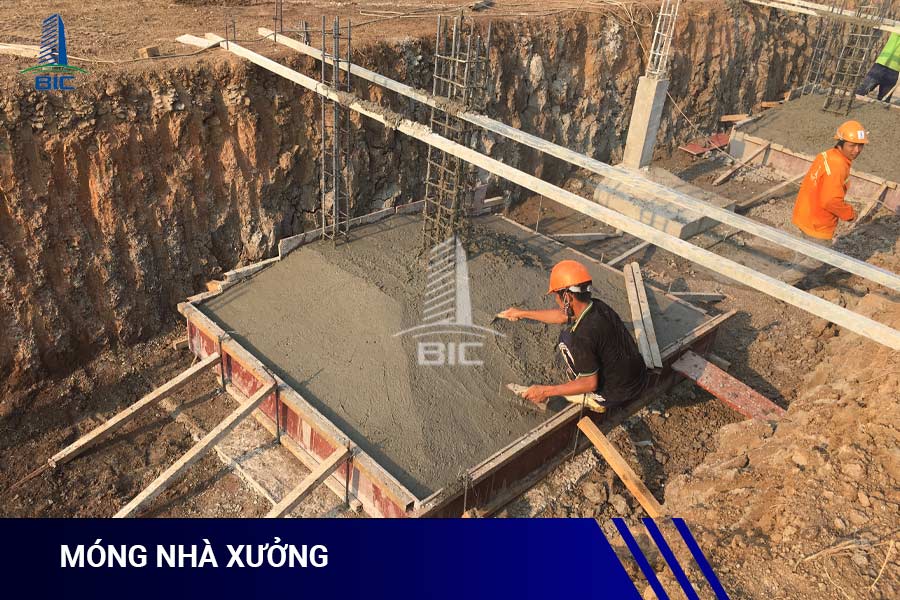

The foundation supports the entire structure, transferring loads from steel frames, beams, and roofs to the soil base.

Depending on geological conditions, isolated, strip, or pile foundations may be chosen.

Anchor bolts must be precisely installed before concrete pouring to facilitate steel column erection.

A well-constructed foundation determines the lifespan and safety of industrial factory construction.

Typically made of reinforced concrete combined with compacted sand layers.

Thickness depends on the load from machinery and internal transportation.

To enhance durability and aesthetics, floors are often coated with epoxy paint for waterproofing, abrasion resistance, and easy cleaning.

Includes steel columns, beams, and trusses, ensuring load-bearing capacity and providing wide production space.

With pre-engineered steel structures, spans up to 100m can be achieved without multiple interior columns, optimizing machinery layout.

Skylights are arranged on roofs to maximize natural lighting and ventilation, reducing electricity costs.

Canopies are designed at entrances and windows, protecting workers and goods from sun and rain.

Steel purlins, often C- or Z-shaped and galvanized, are attached to the main frame to support roofing sheets.

Bracing systems (roof bracing, column bracing, purlin bracing) stabilize and secure the steel frame during erection and long-term use.

Crucial connection elements in factory design.

Consist of bolt body, nuts, anti-rotation pins, and threaded rings.

Ensure strong connections between steel components, maintaining structural stability under heavy loads.

Independently arranged in each span and connected with transverse beams.

Installation must follow technical procedures strictly to avoid bending or joint misalignment.

Color-coated cladding sheets enhance aesthetics while preventing corrosion.

Combined with insulation materials such as fiberglass or air bubble films to reduce heat, minimize noise, and create a comfortable working environment.

For efficient and sustainable operation, industrial factories must be designed according to strict technical standards. This step ensures safety, cost savings, and suitability for long-term production.

Factory design must comply with the Vietnam Construction Code and regulations issued by the Ministry of Construction.

It must also adhere to industry-specific technical standards, especially regarding loads, fire safety, ventilation, and lighting.

Contractors must ensure that all design documents are reviewed and approved before construction.

Structural calculations must be accurate to withstand loads from machinery, goods, wind, storms, and earthquakes.

Materials such as steel and cladding sheets must be corrosion-resistant, fire-resistant, and long-lasting.

Safety features such as emergency exits, fire protection systems, and occupational safety measures must be integrated at the design stage.

Internal spaces must be logically planned for production lines, goods circulation, and vehicle operations.

Pre-engineered steel structures allow wide spans with fewer interior columns, maximizing usable space.

Ventilation, natural lighting, and insulation solutions must be carefully calculated to create a comfortable working environment and save energy.

Modern factory design must consider future expansion needs.

Pre-engineered steel frames allow easy upgrading or functional changes without affecting operations.

Beyond technical aspects, factory architecture should also ensure aesthetics.

A modern and well-designed factory enhances corporate image and builds trust with partners and customers.

In today’s development trends, steel structures are considered the superior solution in industrial factory design construction. Using pre-engineered steel not only ensures technical efficiency but also optimizes investment costs, timelines, and long-term expansion.

Steel structures are lighter than reinforced concrete, reducing foundation loads and saving foundation construction costs.

Prefabricated components limit labor and material costs at construction sites.

Factories can be put into operation quickly, shortening investment cycles.

Steel components are prefabricated according to design drawings and only need on-site assembly.

Construction time is shortened by 30%–50% compared to traditional methods.

High tensile strength: Steel materials withstand heavy loads with minimal deformation.

Resistant to harsh environments: Designed to endure wind, storms, earthquakes, and adverse conditions.

Long lifespan: With anti-rust coatings and galvanization, structures remain durable for many years, reducing maintenance costs.

Factories built with steel structures can be easily expanded, upgraded, or repurposed without structural disruptions.

This is ideal for fast-growing industries with frequently changing production lines.

Prefabrication reduces construction waste at sites, helping protect the environment.

Steel is recyclable, aligning with sustainable construction trends.

When combined with insulation, ventilation, and natural lighting solutions, factories become durable, eco-friendly, and energy-efficient.

To build a standard factory, the design and construction process must follow scientific steps to ensure accuracy and efficiency. Proper procedures not only shorten project timelines but also improve quality and longevity.

Conduct soil surveys, site measurements, and analyze production industry requirements.

Based on collected data, consultants propose optimal design plans that balance functionality, safety, and cost efficiency.

Include architecture, structure, electrical systems, water supply, ventilation, and fire protection.

Technical parameters such as span, load, and roof slope must be accurately calculated.

Design documents must be reviewed and approved before construction begins.

After completing design drawings, all steel components are manufactured in factories with high precision.

This closed production process ensures material quality and minimizes errors during construction.

Prefabrication significantly shortens on-site assembly time, improving efficiency.

Components are transported to the site and assembled according to design specifications.

This includes erecting the main frame, installing purlins, bracing, roofing sheets, cladding, and other supporting works.

Construction must be closely supervised to ensure quality, safety, and compliance with standards.

After the structural frame is completed, finishing works include protective coatings, doors, skylights, canopy roofs, and accessories.

Electrical and fire protection systems are installed simultaneously.

The project undergoes inspection and quality assessment before acceptance.

Finally, the factory is handed over to the investor, ready for operation.

The structural system is the foundation determining the quality, durability, and efficiency of an industrial factory. Investing from the beginning in a professional design and choosing the right construction solution helps businesses save costs, shorten timelines, and ensure safety throughout operation.

If you are looking for a comprehensive solution for industrial factory design and construction, contact BIC for expert consultation, detailed quotations, and full support throughout your project implementation.