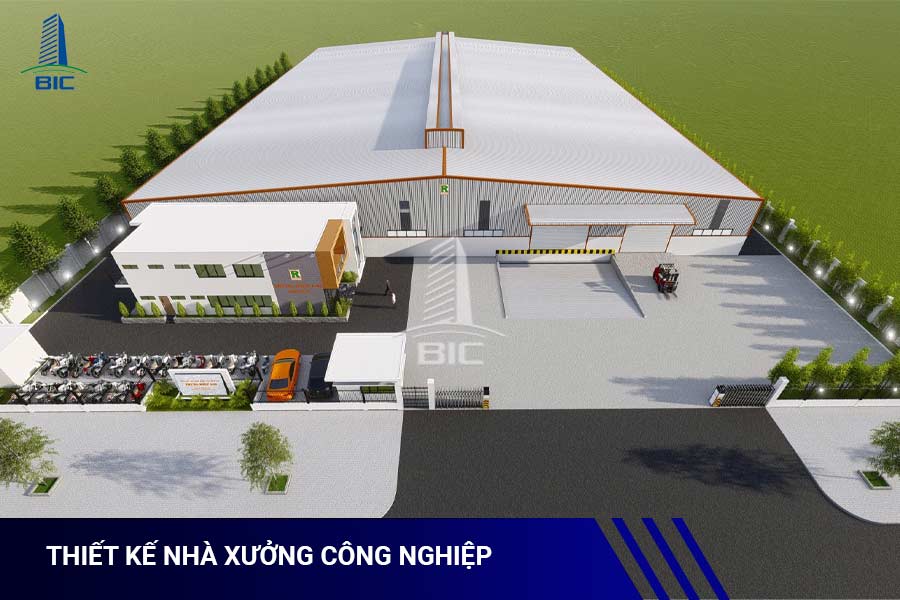

In the process of investing in and expanding production scale, a professional factory design is the foundation for ensuring investment efficiency, saving costs, and maintaining long-term operations. A factory is not simply a place to install machinery and production lines but also a space that directly affects productivity, safety, and future expansion potential.

Choosing the right industrial factory design helps businesses optimize space usage, control construction costs, and facilitate smooth operations. From flexible pre-engineered steel frame factories, standard-compliant food production plants, to processing workshops or packaging factories, each model has its own characteristics tailored to the specific needs of different industries.

Industrial factory design is the process of creating concepts, arranging layouts, calculating structural elements, and drafting detailed drawings for the entire factory project. It is not only architectural sketches but also includes technical systems, construction methods, and future operational solutions.

A design can be considered the “blueprint” that helps engineers, contractors, and investors clearly visualize the project before construction, minimizing errors and ensuring accuracy at every stage.

The core of industrial factory design lies in meeting three elements simultaneously: functionality, safety, and economic efficiency.

- Functionality ensures logical layout of production spaces, warehouses, management offices, and auxiliary areas.

- Safety is reflected in the structural load capacity, compliance with fire protection standards, and construction regulations.

- Economic efficiency comes from proper material estimation and choosing appropriate structural solutions that both save costs and ensure durability.

A well-designed industrial factory provides practical benefits. Drawings help investors visualize the project clearly, avoiding discrepancies between initial concepts and actual construction. Design also enables accurate calculation of materials, labor, and potential costs, helping businesses manage budgets and project schedules. Moreover, it serves as the legal basis for submitting to authorities for approval, ensuring the project complies with regulations.

In reality, many businesses face challenges when expanding because their original factory design did not account for long-term development. This highlights the importance of design not only meeting current needs but also preparing for the future. For example, in textiles, footwear, packaging, or electronics industries, the need for expansion is constant. If the design includes provisions for additional floors, extended floor area, or increased infrastructure capacity, future investments will be much smoother and more cost-effective.

Additionally, industrial factory design is closely linked to environmental considerations and sustainable development. Making use of natural light, designing efficient ventilation, installing solar energy, or using eco-friendly materials can all be integrated during the design phase. These not only reduce operational costs but also enhance corporate image in the eyes of partners and customers.

In short, industrial factory design is not just a technical drawing, it is a long-term investment strategy. A good design helps businesses control costs, optimize production processes, and build a foundation for sustainable development.

The design process is a systematic series of steps that ensures the project meets production needs while complying with technical and legal standards. A standard design involves not only layout drawings but also site surveys, analysis of production specifics, structural solutions, and cost calculations. Key steps include:

Before drafting, engineers must survey the site in detail measuring area, assessing soil properties, load-bearing capacity, wind direction, sunlight, and surrounding infrastructure. These results form the foundation for the initial concept suited to the company’s industry.

After developing concepts, the design unit proposes architectural and structural options. For example:

- Large-scale factories often favor pre-engineered steel frames for flexibility and fast construction.

- Multi-story warehouses may require reinforced concrete for durability.

At the same time, infrastructure solutions such as internal roads, water supply and drainage, electricity, fire protection, and waste treatment are determined. Selecting the right solution ensures stable, safe, and cost-effective operation.

Environmental and safety factors are top priorities. Engineers must calculate systems for ventilation, dust extraction, and emissions treatment to minimize environmental impact.

Designs must also strictly follow fire safety standards, including emergency exits, automatic alarms, and water storage tanks. These are mandatory for approval and safe operations.

Foundations bear the entire load of the factory, requiring careful design. Depending on soil conditions, engineers may select pile foundations, strip foundations, or raft foundations.

Structural calculations for frames, beams, floors, and roofs must comply with standards such as TCVN 2737:1995 on loads and impacts. The goal is to ensure strength, vibration resistance, and durability over long-term use.

The entire process must comply with Ministry of Construction standards and relevant laws, including occupational safety, building density, height limits, spacing between facilities, and technical corridors. Compliance prevents legal risks and facilitates permit approvals.

Thus, the design process combines careful steps from surveys and proposals to structural calculations and legal compliance each crucial for creating a standard, sustainable project aligned with business growth.

A quality factory design requires careful attention beyond precise drawings, accounting for practical factors. Overlooking details during design may cause major costs or operational inefficiencies later. Businesses should note:

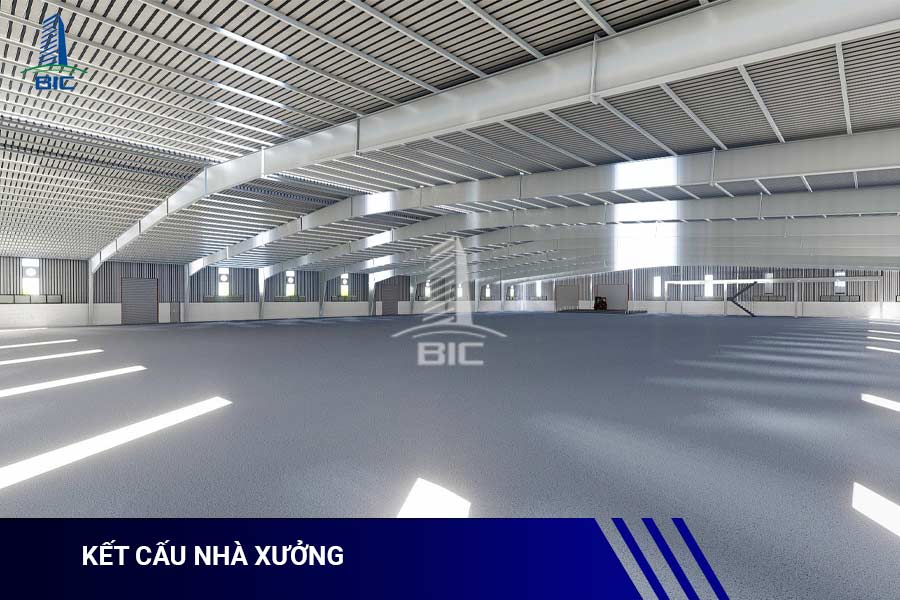

Layout planning is essential. Factories must clearly separate production areas, raw material storage, finished goods warehouses, offices, and auxiliary spaces. Arrangement should follow the production line to minimize transport distance, save time, and cut labor costs. Straight pathways should be prioritized, minimizing intersections to ensure safety.

Modern designs should address both current needs and future growth. Investors should request expansion options additional floor space, new lines, or infrastructure upgrades. This is vital for fast-growing industries such as textiles, packaging, and electronics. Forward-thinking design saves renovation costs and avoids production disruption.

Light and air directly affect worker productivity and health. Designs should maximize natural light through windows, skylights, or translucent roofing. Ventilation both natural and mechanical must be calculated to maintain a comfortable environment, reduce heat, and remove harmful emissions.

Safety is paramount. Factories must include accessible exits, proper spacing for evacuation, and integrated fire protection alarms, extinguishers, sprinklers, and water reserves. Compliance ensures project approval and protects assets and lives.

Construction materials and structural choices impact both investment cost and lifespan.

- Pre-engineered steel: Ideal for large-scale factories due to speed and flexibility.

- Reinforced concrete: Suitable for multi-story or heavy-load facilities, offering long-term strength.

Investors should work closely with designers to balance cost and durability.

Industrial factory design requires a combination of technical expertise, safety standards, and long-term vision. Only with thorough consideration can businesses achieve efficient, sustainable facilities that meet present and future needs.

A successful design depends not only on precise technical data but also on practical experience from completed projects. Investors should keep in mind:

Strong foundations: Conduct thorough soil surveys to prevent costly settlement or cracking.

- Lighting and emergency planning: Combine natural and artificial lighting, ensure clear and sufficient exits.

- Suitable structural systems: Choose pre-engineered steel for fast, large-scale projects; reinforced concrete for durability in multi-story or heavy-load factories.

- Expansion planning: Reserve space for future lines, warehouses, or auxiliary facilities.

- Reputable design partners: Select firms with proven experience, skilled engineers, and full project support from design to operation.

Ultimately, factory design requires careful preparation and strategic vision. Businesses should prioritize safety, sustainability, and scalability over short-term savings to turn factories into long-term competitive advantages.

Beyond general principles and experience, choosing the right design model helps optimize costs and usability. Five common models are:

- Widely used in recent years.

- Components are prefabricated in factories and assembled on-site.

- Advantages: fast construction, lower cost than traditional concrete, and flexible expansion.

- Suitable for light industries, logistics warehouses, component processing, and projects ranging from thousands to tens of thousands of square meters.

- Requires hygienic, safe environments compliant with GMP, ISO 22000, HACCP.

- Special systems for air treatment, ventilation, and lighting.

- Separate areas for processing, packaging, and storage to ensure food safety.

- Suitable for agricultural, seafood, beverage, and FMCG industries.

- Simple, easy to build, focused on large open spaces.

- Often uses transparent or translucent roofing to maximize natural light and reduce energy costs.

- Layout supports printing, molding, plastic forming, and packaging lines.

- Common in carton, plastic, and food packaging industries.

- Common for mechanical processing, electronics, textiles, and furniture.

- Features strong steel structures, easy expansion, and efficient material flow.

- Typically divided into smaller sections to support multi-step processes.

- Advantage: low initial investment with flexibility for production changes.

- Requires spacious, ventilated, and fire-safe design.

- High roofs, natural ventilation, and multiple exits.

- Includes raw material storage, wood drying areas, and finished goods warehouses.

- Suitable for furniture makers, wood exporters, and domestic wood product manufacturers.

Each design model has unique features aligned with industry needs. Choosing the right one not only saves costs but also lays the groundwork for sustainable business growth.

Industrial factory design is a crucial foundation that helps businesses optimize costs, ensure safety, and boost production efficiency. Selecting the right design model tailored to industry characteristics ensures sustainability and scalability.

For the best solutions, partner with a reputable design firm for in-depth consultation and full project support.

If you are looking for effective industrial factory design solutions, contact BIC today for detailed consultation and a tailored quotation. Investing in a quality design is investing in sustainable growth and long-term success.