In manufacturing, investing in an industrial factory isn’t just a necessity, it’s a strategic move to boost operational capacity, scale up, and ensure long‑term competitiveness. A well‑designed industrial plant carries inherent risks in construction, operation, and maintenance that can directly influence production costs, labor productivity, and legal compliance.

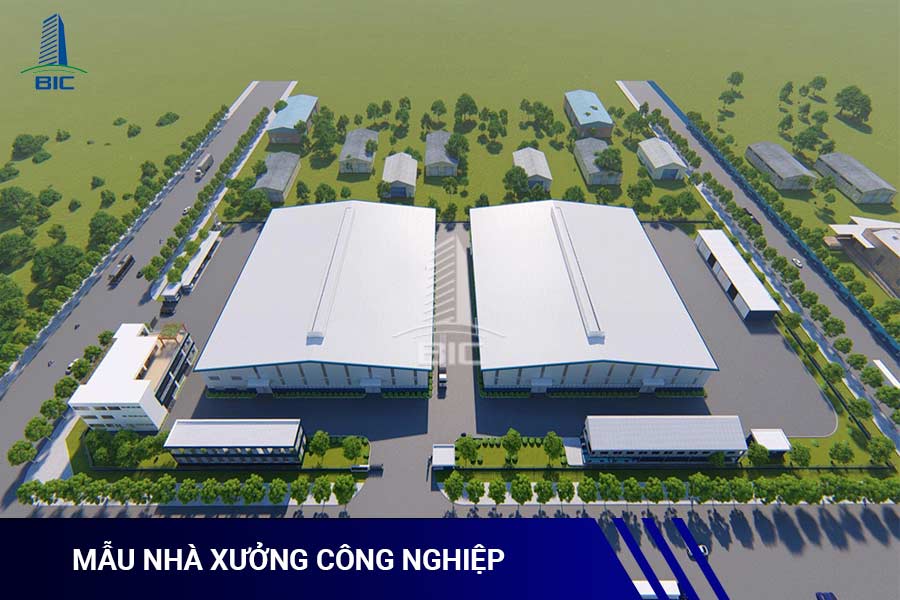

Understanding what an industrial factory is, identifying the elements that make up a standard structure, and examining its real‑world applications in manufacturing, logistics, and supply chain can help investors make informed decisions when designing new facilities or renovating existing ones. In this article, BIC provides a comprehensive view of technical features, structural design, and key considerations during the design and construction phase aligned with modern industrial trends and cost‑efficient investing.

An industrial factory (or warehouse) is a constructed building specifically designed and executed to support manufacturing, processing, assembly, storage, or operation of industrial equipment. Unlike civil (residential or commercial) buildings, industrial facilities prioritize maximizing usable space, ensuring load-bearing capacity for machinery, integrating technical systems, and providing flexibility for expanding production lines.

A compliant industrial factory usually comprises major components such as: a steel or reinforced concrete frame, a load-bearing floor slab, roofing, entries and exits, ventilation, lighting, fire protection systems, water supply and drainage, and internal transport routes.

- Operational hub for production: Houses machines, production lines, and material management systems.

- Supporting the supply chain: Located strategically within industrial zones or near logistic ports, helping optimize warehousing, transportation, and delivery costs.

- Ensuring safety and quality standards: A technically sound design enhances labor efficiency, minimizes accident risks, and meets international standards (ISO, GMP, HACCP, etc.).

- Function: Industrial facilities support large‑scale production; civil structures serve domestic or small business uses.

- Structure: Industrial factoris require heavy‑duty load‑bearing frames (often prefabricated steel or reinforced concrete) and broad, open floor plans.

- Technical systems: Include automated fire‑fighting, wastewater treatment, cold storage, high‑power electrical systems, and ventilation/cooling solutions.

- Regulations and standards: Industrial factories must meet rigorous technical codes, occupational safety, and fire prevention regulations beyond those for civil buildings.

Design emphasizes simplicity, ease of construction, and efficient operations. Typically one story, rectangular or open‑frame with no internal columns, maximizing usable workspace.

- Large footprints to accommodate conveyor lines, storage zones, and heavy machinery.

- Ceiling heights generally range from 6 m to 12 m, depending on production needs.

- Simple structural systems, prefabricated steel or reinforced concrete to reduce build time while ensuring high load capacity.

Industrial buildings are designed to adapt to evolving production demands crucial for companies expanding or diversifying products.

- Internal layout modifications are easy to implement without affecting main structural frames.

- Facilities allow horizontal or vertical expansion (e.g. additional workshops, technical zones, office additions).

- Long‑term investment optimization by enabling scalable upgrades and preventing production downtime.

A modern industrial factory isn’t just an external shell, it must fully accommodate internal operational systems, especially in industries with stringent environmental/safety standards.

- Fire protection systems: Automatic suppression, sprinkler systems, smoke detectors, fire extinguishers compliant with national QCVN standards.

- Ventilation and cooling: Fans, cooling pads, daylight roofing, or industrial HVAC.

- Water supply, drainage, wastewater treatment: Customized per industry (textile, food, chemical, etc.).

- Industrial lighting and power: LED lighting, three‑phase electrical systems, central control panels must support required capacity and safety.

A high‑standard design seamlessly integrates structural foundations, flooring, shell systems, and technical installations ensuring load capacity, operational efficiency, and easy long‑term maintenance.

The foundation supports the entire load of structure, machinery, and operations. Depending on soil and design loads, options include isolated footings, strip foundations, pile foundations, or specially reinforced slabs.

- Floor slab: Reinforced concrete M250–M300, typically 150–200 mm (or thicker) with steel reinforcement. It must be level, wear‑resistant, and chemically protective where needed.

- Technical requirements: Mitigate settling and cracking; expansion joints to reduce long‑term cracking.

This is the main load‑bearing frame. Prefabricated steel frames are increasingly popular for their flexibility, construction speed, and expandability.

- Steel structure: Columns, rafters, purlins, and bracing of composite or structural steel, often galvanized or painted for corrosion resistance.

- Reinforced concrete: Preferred for higher fire resistance or very large loads.

- Design requirements: Must account for wind loads, machinery/heavy loads, overhead cranes (if any), and safety factors per TCVN or Eurocode standards.

The shell not only protects the factory but helps create stable production environments (temperature, lighting, noise).

- Roof: Galvanized insulated metal sheets (PU or Rockwool), daylight panels, gutter systems, and drainage pipes.

- Walls: Options include panel cladding, fire‑resistant panels, or masonry depending on the production type.

- Rolling doors, sliding doors, ventilation: Integrated to support forklifts and trucks and maintain good airflow.

Modern factory design must include infrastructure reserves for technical systems (electricity, water, compressed air, fire protection) and layout planning to allow upgrades or scaling without disrupting existing structure.

- Central electrical panels, underground technical conduits, sub‑stations, wastewater treatment tanks should be accounted for at the schematic design stage.

- Fire safety, lighting, and emergency exit systems must comply with QCVN 06:2022/BXD and TCVN 3890.

A structured, standards‑based process not only reduces investment costs, but also ensures schedule, quality, and scalability. Typical key steps include:

- Terrain and geotechnical survey to determine soil conditions, groundwater levels, and appropriate foundation design.

- Production function analysis: types and numbers of machines, production zones, storage, office spaces, and industry‑specific requirements.

- Legal and zoning review: alignment with local master plan, building lines, density, and height restrictions.

- Master layout: Functional zoning, optimized material and personnel flow.

- Architectural and structural design: Frame, foundation, roof, doors, internal routes.

- Technical systems design: Fire protection, water supply/drainage, three‑phase electricity, compressed air, wastewater treatment (if applicable).

- Cost estimation: Materials, labor, schedule, and overall investment cost.

This provides the legal and technical foundation for construction bidding, permitting, or execution.

- Site preparation: leveling, pile driving, temporary fencing, storage setup.

- Foundation and floor construction: maintaining levels, flatness, and bearing capacity.

- Structural erection: columns, rafters, purlins, roofing, walls.

- Installation of technical systems: electricity, water, ventilation, lighting, fire safety systems.

- Finishing touches: anti‑corrosion coating, waterproofing, floor finishing, doors, and auxiliary equipment.

- Staged acceptance: foundation, structure, systems.

- Verification against design drawings and building standards.

- As‑built documentation, handover, and operational instruction.

Ensure the factory meets operational readiness and legal certification, including environmental or fire safety permits.

Choosing a firm experienced in both design and construction is critical to minimize risk, ensure regulatory compliance, and maximize long‑term investment value.

An industrial factory is more than just a production space it serves as a strategic link throughout the value chain from manufacturing to transportation, storage, and distribution. Key application areas include:

Most modern industries require specialized factory design to support closed‑loop workflows, hygienic standards, safety, and high efficiency. For example:

- Food industry: Clean facilities, wastewater treatment, dust‑resistant ceilings/walls, food‑grade materials.

- Apparel, leather, footwear: Spacious, well‑ventilated zones with separate working areas.

- Machinery and metals: Heavy‑duty structures, overhead crane integration, smoke extraction, vibration‑resistant flooring.

- Electronics and components: Cleanrooms, temperature/humidity control, and anti‑static measures.

- Packaging and printing: Seamless layout for printing, cutting, packaging, and warehousing with good transport linkages.

Beyond production, industrial factories are widely used in logistics and storage—especially near seaports, highways, or industrial zones.

- Distribution Centers (DCs): Require systematic layout and can integrate conveyor belts, forklifts, and factory management systems (WMS).

- Cold storage and refrigerated factories: Used in food, pharmaceuticals, seafood; need strong insulation and advanced cooling equipment.

- Bonded or tax‑indoor storage: Require security control, network integration, and fast import/export processing.

Factory design must ensure infrastructure connectivity and meet operational standards per warehouse type.

Aligned with digital transformation and Industry 4.0, modern industrial factories adopt advanced solutions to enhance productivity and reduce costs.

- IoT (Internet of Things): Remote monitoring of machinery, alerts, energy/water/temperature tracking.

- Production automation: Integration of industrial robots, automatic conveyors, and quality-control sensors.

- Energy Management Systems (EMS): Optimize electricity, lighting, and ventilation in real time.

- Factory operations software: Digitizing everything from equipment to personnel and generating real‑time reports.

This is an essential trend in sustainable, green‑growth focused factory design boosting production efficiency and professional factory image.

A well‑designed factory not only optimizes space and operational function, but also enables technological integration, increases output, and elevates professional branding. If you're planning to build a new industrial factory or expand or upgrade an existing production facility, consult the BIC expert team committed to guiding you from survey and concept, through design and construction, to handover, delivering long-term value for your business.