What standards must a factory design meet to ensure safety, cost-effectiveness, and compliance with legal regulations? This is a crucial question that every investor or manufacturing business must address before beginning construction. Adhering to standards in planning, structure, fire prevention, environmental protection, and legal procedures not only ensures efficient operations but also reduces long-term risks. In this article, BIC will analyze the most important factory design standards that you need to understand.

In industrial construction, factory design standards are not merely a set of technical rules they form the foundation for ensuring a building's safe, efficient, and legally compliant lifecycle. Adhering to standards from the design stage significantly impacts operational efficiency, maintenance costs, expandability, and long-term asset value.

A compliant factory design ensures:

- Optimized functionality and internal circulation: Logical zoning and layout of material, equipment, and labor movement according to production workflows help save time, reduce energy loss, and increase operational efficiency.

- Reduced technical risks: Factories typically house heavy machinery and run continuously, posing high fire and explosion risks. If the structural foundation, electrical, and water systems are not designed to standards, serious accidents could occur, threatening property and worker safety.

- Minimized unforeseen costs: A flawed design may require adjustments during construction—or worse, retrofitting after completion. These hidden costs can inflate the budget and delay project timelines.

- Regulatory approval prerequisite: All factory constructions must undergo assessment and approval by regulatory agencies before construction and operation. Failure to meet standards in structure, fire safety, and environment may result in suspension or rejection.

Compliance and supervision in factory design are handled through interagency coordination, involving multiple levels of authority and technical organizations:

- Department of Construction: The main body responsible for evaluating technical design documents, ensuring alignment with planning, building density, and structure, and issuing building permits.

- Fire and Rescue Police Department: Reviews, approves, and inspects fire prevention systems, emergency exits, fireproof materials, etc., in accordance with national fire safety codes.

- Department of Natural Resources and Environment (DONRE): Oversees environmental impact assessments (EIA), wastewater and emission treatment systems to ensure no pollution is caused during operations.

- Ministry of Health: For factories in food, cosmetics, and pharmaceuticals, this agency enforces GMP (Good Manufacturing Practices) standards, including clean room requirements, dust and airflow control, isolation zones, and production line segregation.

- International Organizations: Factories that export goods or seek ISO, LEED, HACCP certifications undergo independent verification based on global standards.

Even if drawings meet all standards, actual implementation must be supervised and executed by licensed professionals well-versed in industry regulations and legal updates. Design firms translate rules into practical solutions, while contractors turn designs into reality. A weak link at any stage can lead to unapproved or inefficient buildings.

Complying with factory design standards is not only a legal obligation—it’s a strategic decision that affects investment costs, operational timelines, safety, company reputation, and future scalability. In an era of increasingly stringent regulations on construction, fire safety, and environmental protection, meeting standards is no longer optional—it’s mandatory.

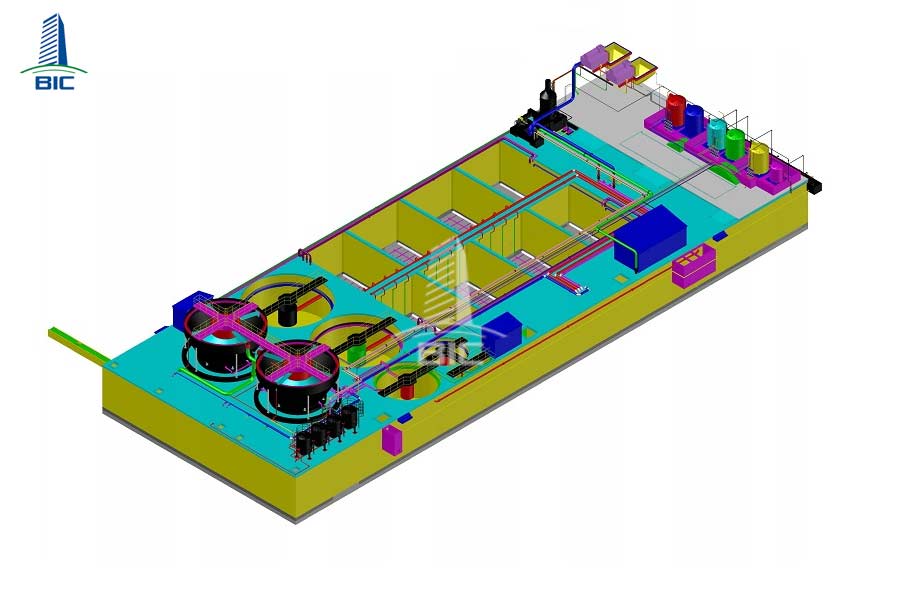

Factory designs must adhere to comprehensive planning standards to ensure operational efficiency, safety, and regulatory compliance. A well-structured site layout optimizes space use, facilitates internal movement, and accommodates future expansion.

- TCVN 4449:1987 – General industrial site planning: Specifies spacing between components like warehouses, production facilities, and support areas.

- QCXDVN 01:2008/BXD – Urban planning code: Applies to industrial parks and residential areas, determining building density and land use ratios.

- Clearly defined zones for production, administration, technical functions, and storage.

- Logical internal traffic layout with adequate road width for trucks and fire engines.

- Safe distances between factory buildings and residential areas, water sources, and electrical substations.

Factory structures must be stable, functional, and easy to construct and maintain. Proper structural design ensures safe operation and reduces structural risks.

- TCVN 2737:1995 – Loads and actions on structures.

- TCVN 5574:2018 – Reinforced concrete structures.

- TCVN 5575:2012 – Steel structural design.

- Factory height must accommodate equipment, cranes, and HVAC systems.

- Large column spacing (span) for flexible production line layout.

- Strong, settlement-resistant foundations suitable for soil conditions.

- Roofs with good drainage slope, heat, and noise insulation.

The MEP system is the operational backbone of any factory. A well-designed MEP system saves energy, ensures safety, and simplifies maintenance.

- TCVN 9206:2012 – Industrial electrical design.

- TCVN 4474:1987 – Water supply design.

- TCVN 4519:1988 – Drainage system design.

- TCVN 7114-1:2008 – Workplace lighting.

- Electrical system: Logical layout, certified equipment, high-load cables, lightning protection.

- Water systems: Separate designs for restrooms, production areas, stormwater, and wastewater.

- Lighting: A mix of natural and industrial lighting, providing sufficient lux levels per area.

- Ventilation and air conditioning: Ensure safe working conditions and prevent toxic gas accumulation.

Fire safety is strictly enforced by authorities. A compliant fire protection system safeguards people and assets.

- QCVN 06:2022/BXD – National fire safety technical regulations.

- TCVN 2622:1995 – Fire protection for buildings.

- Clearly marked and accessible emergency exits.

- Fire alarm and automatic sprinkler systems, handheld extinguishers.

- Firewater tanks and pumps as required.

- Smoke extraction systems and fire-rated doors in critical areas.

Factory designs must be environmentally friendly and safe for workers. These are legal mandates and reflect corporate social responsibility.

- QCVN 05:2013/BTNMT – Ambient air quality.

- QCVN 40:2011/BTNMT – Industrial wastewater.

- QCVN 07:2009/BLĐTBXH – Workplace safety.

- Emissions, noise, and dust must be treated to meet discharge standards.

- Wastewater and grease treatment systems required, especially in kitchen areas.

- Emergency exits, lighting, and warning signs must be properly installed.

- Provide protective gear, medical rooms, and resting areas for workers.

Depending on the industry, many factories must meet international standards to qualify for production, export, or investment approvals. These standards greatly influence architectural, technical, and construction process designs.

- GMP: For pharmaceuticals and functional foods – requires clean zones, dust control, staff/material flow management.

- ISO 9001:2015: Quality management systems – affects how production processes are arranged.

- ISO 14001:2015: Environmental management.

- ISO 45001:2018: Occupational health and safety.

- LEED, EDGE: Green buildings – focused on energy efficiency and eco-friendly materials.

A standard-compliant factory design must be prepared by a legally certified firm and approved by authorities before construction.

- Construction permit.

- Environmental Impact Assessment (EIA).

- Fire safety approval.

- Complete construction design dossier, including architecture, structure, electrical, plumbing, and fire safety.

- Investor: Selects qualified firms and verifies documents.

- Design Firm: Ensures technical standard compliance.

- Government Authorities: Inspect, evaluate, approve, and certify the project.

Factory design is not just a matter of architecture and functionality, it’s a rigorous process combining engineering, legal, and environmental compliance. A standard-compliant design helps businesses cut costs and forms a solid foundation for sustainable development.

As such, the question "What standards must be met in factory design?" is not merely technical, it’s a decisive factor in the long-term, safe, and sustainable operation of a business. Full compliance with standards covering planning, architecture, structure, MEP, fire safety, environment, legal procedures, and international certifications helps investors avoid risks, optimize budgets, and increase project value.

Rather than focusing solely on cheap design costs, businesses should invest from the outset in a professional, experienced design firm. This not only ensures standard compliance but also supports long-term development and competitiveness in modern manufacturing.