The regulations regarding the design standards for food industry factories specify each design item, requiring investors, design units, and construction contractors to strictly adhere to the technical standards in the construction of factories.

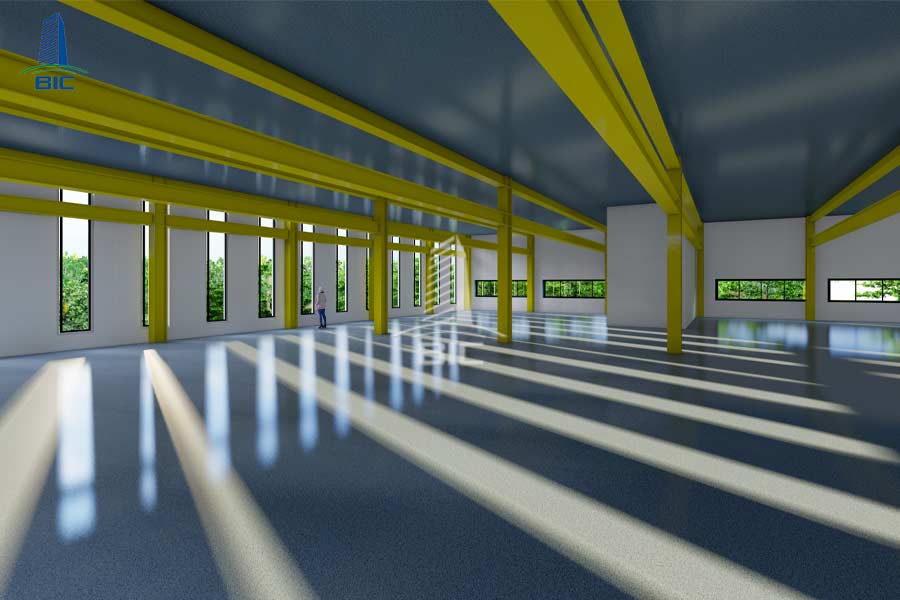

Construction standards for industrial buildings play a crucial role in assessing the overall quality of the project. Therefore, BIC emphasizes that before commencing the construction of a factory, a thorough understanding of the technical requirements is a key factor in ensuring the project meets standards and operates effectively.

Industrial factory design must meet standards for the following reasons:

- Safety: Design standards ensure the safety of workers, machinery, and goods during the production process. Factors such as electrical systems, fire prevention and control systems, ventilation, lighting, and emergency exits are carefully considered to minimize the risk of accidents and incidents.

- Efficiency: A factory designed to standards helps optimize space and production processes, thereby increasing productivity and reducing operating costs. The layout of machinery, equipment, and production lines is organized to save time and effort while minimizing material waste.

- Quality: Design standards ensure the quality of the products being produced. A clean, well-ventilated working environment with controlled factors such as temperature and humidity helps ensure stable product quality that meets customer requirements.

- Compliance: Factory design must comply with legal regulations and industry standards. This helps businesses avoid legal risks and ensures smooth production operations.

- Sustainability: Design standards encourage the use of environmentally friendly materials and technologies, helping to minimize negative impacts on the environment and create a sustainable working environment.

In summary, designing industrial facilities that meet standards is a crucial factor in ensuring safety, efficiency, quality, and regulatory compliance, which in turn helps businesses develop sustainably and compete in the market.

When choosing a location for food production facilities, special attention must be paid to environmental factors to ensure food safety. The facility should not be located in areas with a high risk of contamination, even if protective measures are implemented, as there may still be risks affecting product quality.

Food production facilities should be situated away from the following areas:

- Pollution-prone areas: Avoid proximity to industrial activities, densely populated residential areas, or places with a high risk of food contamination.

- Flood-prone areas: Do not build in low-lying regions that are prone to water accumulation or flooding, unless effective preventive measures are in place.

- Areas with pest risks: Avoid placing the facility near landfills or sources of solid or liquid waste that cannot be thoroughly managed.

Additionally, the internal road system within the facility must be constructed to meet hygiene standards, with a closed drainage system to prevent environmental pollution. Furthermore, the location of the facility should have a plentiful supply of clean water and convenient transportation access to ensure efficient production operations.

To ensure food safety and maintain production quality, factories must meet strict technical standards, including:

- Controlling contamination levels: Measures should be implemented to minimize contamination during the production process, and strict cleaning and sanitation procedures should be established to eliminate dirt, bacteria, and harmful agents.

- Reasonable design and layout: The factory design layout must be scientifically arranged, facilitating maintenance and sanitation. The ventilation and exhaust systems must be effective, minimizing air pollution within the factory.

- Using safe and sustainable materials: Choose clean, non-toxic, environmentally friendly building materials. The surfaces of floors, walls, and ceilings should be easy to clean and maintain to ensure safe production conditions.

- Controlling temperature and humidity: Cooling and ventilation systems must maintain temperature and humidity within permissible ranges, suitable for each type of product. Avoid mold, condensation, and moisture that could affect food quality.

- Protecting food: Implement measures to control insects and pests from the outside, such as screens, traps, or safe chemicals. Ensure that doors and windows are designed appropriately to prevent the intrusion of bacteria, mold, and parasites.

Full compliance with these standards not only helps the factory operate efficiently but also enhances product quality and ensures food safety.

To ensure food safety and create an efficient production environment, the design of the workshop must adhere to the following technical requirements:

- The production line should be designed according to a one-way principle, from raw materials to finished products, to minimize the risk of cross-contamination and ensure hygiene.

- Doors and windows should be made from sturdy materials that can prevent the entry of insects, dust, and other harmful agents from the outside. The doors need to be designed for easy cleaning and the transportation of raw materials and products.

- The ceiling and any equipment installed on it must be securely fixed, resistant to dust accumulation, and minimize moisture buildup to avoid condensation that could affect food quality.

- Floors, steps, and staircases should use durable, non-slip materials that are easy to clean to ensure the safety of workers. Additionally, the floor must have a reasonable slope for effective drainage, preventing stagnant water that could compromise hygiene.

- Walls and partitions should be made from waterproof materials with smooth surfaces for easy cleaning. The structure must be designed to be sturdy, facilitating maintenance and ensuring a clean and safe production environment.

- Dust control and environmental hygiene: use materials that limit dust, preventing spillage during production. The ventilation and exhaust systems must be effective in preventing dust and moisture accumulation.

Adhering to these standards not only helps maintain product quality but also enhances work efficiency, creating a safe and clean production environment.

Factory design with a ventilation system plays a crucial role in maintaining a clean, safe, and efficient production environment. The objectives of this system include:

- Controlling and minimizing air pollutants such as dust, bacteria, and chemical vapors during the production process.

- Maintaining a stable temperature to ensure that the temperature within the factory remains within regulated limits, suitable for different types of food products and the working conditions of employees.

- Controlling humidity and food odors to prevent condensation, maintaining optimal humidity levels to avoid mold and bacterial growth, and effectively managing food odors in the production space.

The ventilation system can be designed using various methods, including natural ventilation and mechanical ventilation, depending on the scale and characteristics of the factory.

The lighting system must ensure adequate illumination to enhance labor productivity and ensure safety during the production process. Key requirements include:

- Providing sufficient and uniform lighting: Utilizing natural or artificial light to ensure that the workspace is always well-lit, helping workers perform tasks accurately, reducing errors and fatigue.

- Lighting fixtures should be installed appropriately to avoid glare or shadows that could affect visibility.

- Prioritizing the use of LED lights, light sensor systems, or optimized designs to take advantage of natural light and reduce energy consumption.

The harmonious integration of the ventilation and lighting systems not only helps maintain a comfortable working environment but also contributes to improving production quality and ensuring food safety standards.

The design of water and waste treatment systems in food industry facilities must ensure safety, efficiency, and compliance with current regulations to maintain hygiene and protect the environment.

The water supply system in the facility serves various purposes, including food production, cooling, fire protection, and wastewater treatment. To ensure effective use and convenience in maintenance, the following principles must be adhered to:

- The plumbing system should be painted in distinct colors for easy identification and to avoid confusion during operation and maintenance.

- Separation of potable and non-potable water: The system supplying clean water for food production must be completely separate from the non-potable water system to prevent cross-contamination and ensure food safety.

Waste management in the facility must meet environmental and food safety standards. Key requirements include:

- Continuous operation and regulatory compliance: The waste treatment system must operate efficiently and continuously, adhering to the regulations set forth in Decree 38/2015/ND-CP on waste and scrap management.

- Reasonable waste storage area layout: Solid and liquid waste must be collected, sorted, and treated separately. The waste storage area should be located away from production areas and raw material storage to avoid the risk of cross-contamination.

Full compliance with the design standards for water and waste treatment systems is crucial for businesses to maintain sustainable production operations, enhance product quality, and build a professional brand image in the food industry.

The above are important standards in the design of food production facilities, helping to ensure hygiene and safety, enhance product quality, and optimize production operations. BIC hopes that this information will be useful for businesses looking to plan the construction or improvement of their production facilities. If you need more information or design consultation for food industry facilities, please contact us.