When starting a factory construction project, one of the most important questions most investors ask is: “How long does it take to design a factory?” Because the design timeline directly affects the construction schedule and determines when the plant can begin production a crucial factor in calculating costs and profits.

In reality, there is no fixed number for design time, as it depends on many factors such as the factory’s scale, type of production, complexity of technology, and accompanying legal procedures. However, by understanding the design phases and knowing how to optimize each step, businesses can absolutely shorten the time while still ensuring the quality of the design documentation.

In this article, BIC will provide a detailed breakdown of factory design timelines, the factors influencing progress, and how businesses can proactively manage the process to accelerate it.

On average, factory design takes around 15 working days, depending on the project’s scale and technical complexity. This time is necessary to ensure the drawings meet technical standards and are suited to the business’s operational needs.

Here is an estimated design timeline based on the factory's area:

|

Factory Size |

Estimated Design Time |

|

Under 1,000 m² |

10 – 15 working days |

|

1,000 m² to under 5,000 m² |

20 – 30 working days |

|

Over 5,000 m² |

From 30 days, depending on complexity |

Medium factories (1,000 – 5,000 m²) often support medium-scale production lines, requiring detailed layouts and technical systems. Design takes 20–30 days.

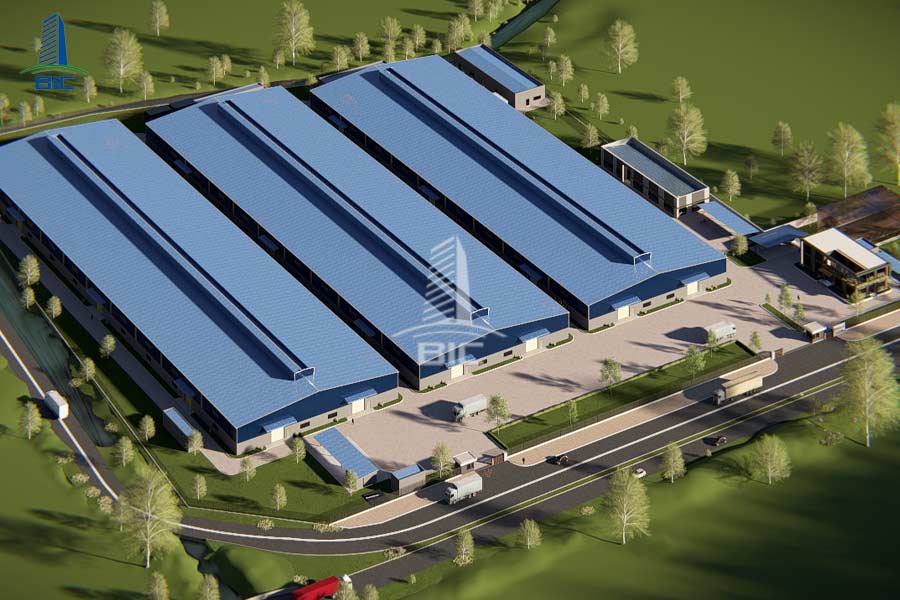

Large factories (5,000 m² or more) or those with multiple functions (offices, warehouses, treatment zones...) may take over 30 days due to detailed coordination and adjustments during the process.

Accurately estimating design time helps investors plan construction, manage costs, and coordinate resources effectively. The following sections analyze each design phase and the factors affecting the timeline.

To complete a full set of factory design documents, the process generally goes through four key phases. Each stage is crucial to ensuring both quality and on-time delivery.

This critical first step involves understanding the actual site conditions:

- Measuring and defining site boundaries.

- Evaluating topography, geology, and current infrastructure.

- Collecting legal information, zoning plans, and investor needs.

A thorough site survey helps prevent errors and reduces later revisions.

Architects and engineers provide initial layout solutions, including:

- Positioning of workshop, office, parking, storage, and support zones.

- Workflow and movement planning.

- Preliminary infrastructure ideas: internal roads, power, drainage.

Early conceptual approval helps visualize the overall plan and allows timely adjustments before going into detailed drawings.

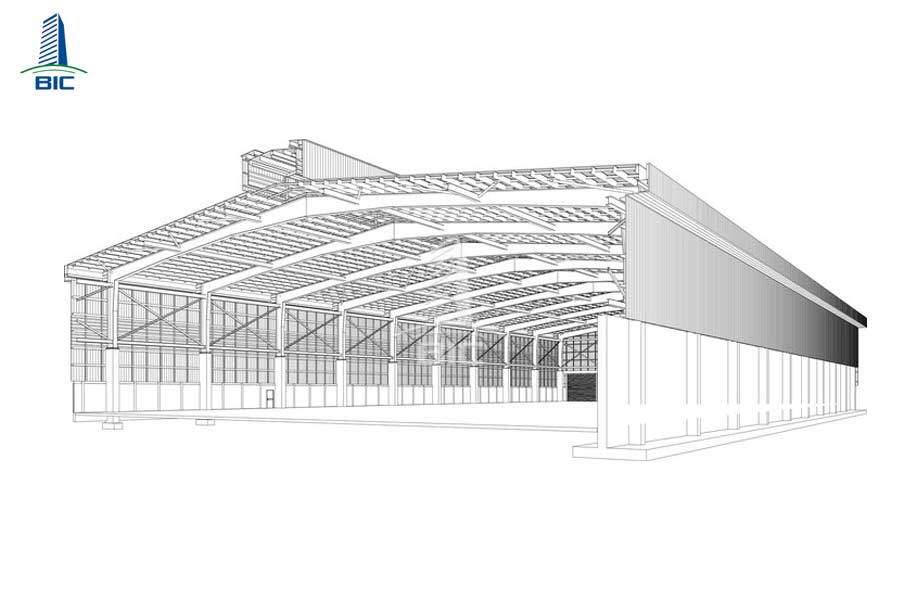

This is the most crucial phase, requiring tight coordination across disciplines:

- Architectural drawings: layouts, elevations, cross-sections.

- Structural plans: foundations, beams, columns, slabs, steel or concrete frameworks.

- MEP systems: electrical, water supply, ventilation, fire protection...

Depending on complexity and compliance standards (GMP, ISO, HACCP, etc.), this phase can last 7 to 20 days or more.

In many cases, the design documents are used to apply for construction permits:

- Architectural, structural, infrastructure drawings as per regulations.

- Legal land-use papers and zoning documents.

- Fire protection certification and environmental approvals (if required).

Having a complete, regulation-compliant dossier from the outset saves time and reduces correction delays.

Understanding each design phase enables better project control and smoother coordination with the design and construction teams.

Design time is not fixed it depends on many variables. Understanding these helps businesses plan effectively and avoid unnecessary delays.

The bigger and more complex the factory, the longer the design. Projects with multiple blocks (workshops, offices, treatment zones...) or special structural requirements increase drawing and review time.

Different industries require different design approaches:

- Heavy mechanical workshops need high load-bearing designs, deep foundations.

- Food factories demand hygienic, closed-loop processes.

- Electronics factories require dust control, cooling, and EM shielding...

These differences impact layout planning and MEP systems, affecting the design time.

If the factory needs to meet international standards, more time is required to ensure every element complies. For example:

- GMP compliance involves specific movement flows, material choices, and environmental control.

- Fire safety needs detailed drawings and approval from the authorities.

Slow responses, multiple revisions, or mid-process changes from the investor can significantly extend timelines. Fast, clear communication and consistent decisions help speed up the process.

Experienced, professional design firms with efficient processes deliver faster, more accurate drawings. They also anticipate risks and propose optimal solutions early on, avoiding rework.

In short, choosing the right partner and preparing thoroughly enables on-time design completion and smoother execution.

Shortening design time not only accelerates construction but also reduces idle costs and brings the project into operation sooner. Here are some effective solutions:

Investors should provide:

- Land size and legal papers.

- Intended use, production type, machinery and manpower.

- Required standards (GMP, ISO, fire safety...).

- Future expansion plans.

Clear, early communication reduces revisions and speeds up design.

A professional industrial design firm with experience will:

- Execute survey–design–legal steps efficiently.

- Proactively propose solutions and minimize redesigns.

- Communicate effectively and respond quickly at each stage.

They also often have design templates to fast-track initial planning.

Design delays often stem from late investor feedback or changing ideas. Avoid this by:

- Assigning one consistent contact person for the project.

- Reviewing and responding to each submission on schedule.

- Using written communication to prevent misunderstandings.

Tools like 3D rendering or Building Information Modeling (BIM) help:

- Visualize the building before construction.

- Detect technical conflicts early (clash detection).

- Optimize MEP and structural systems.

These technologies reduce revision time compared to traditional design.

Instead of waiting for complete drawings before starting legal work, businesses can:

- Consult legal and prepare permits alongside design.

- Let the design firm support the paperwork to ensure alignment.

This is especially useful for projects requiring construction permits or environmental impact assessments.

In conclusion, shortening design time isn’t about rushing it’s about doing it right: clear communication, proper coordination, and working with the right partner.

Factory design time is not fixed it depends on project size, production type, technical standards, and coordination among stakeholders. However, with good preparation, the right design partner, and streamlined processes, businesses can confidently reduce design timelines without compromising quality or legal compliance.

Let BIC accompany you from site survey, design, permit application to turnkey construction. Contact us today for a free consultation and a tailored factory design plan that fits your business needs efficiently, professionally, and cost-effectively.