The fire prevention and fighting design approval (PCCC) for factories is the first step in ensuring that a facility complies with Vietnam’s national technical regulations (QCVN) and standards (TCVN) regarding fire safety. Properly following the process not only guarantees operational safety and mitigates fire and explosion risks, but also serves as a prerequisite for obtaining construction permits and final project acceptance.

However, many businesses remain unclear about PCCC approval procedures, recent legal updates, and how to prepare a compliant dossier to avoid delays in approval. In this article, BIC will help you clearly understand the entire process, provide the latest regulatory updates, and point out common errors that cause project rejection helping businesses be more proactive in their factory construction plans.

PCCC approval is a mandatory process in which an authorized government body—typically the Fire Prevention and Fighting and Rescue Police Department or the provincial Fire Police reviews, evaluates, and approves the entire fire protection design documentation before construction begins. This is a crucial step in the legal process to ensure that factories fully comply with fire safety regulations and standards.

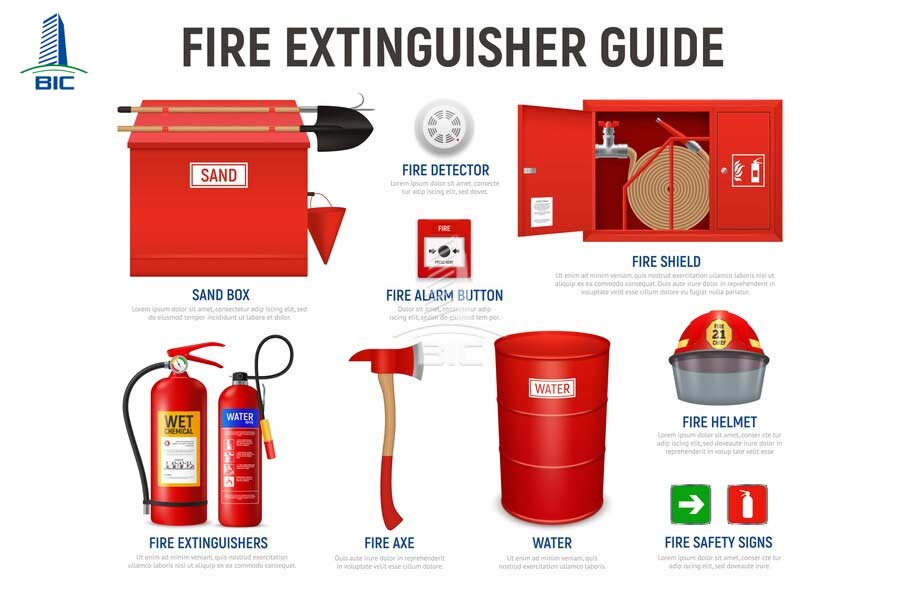

In practice, PCCC approval is not just a formality it is a technically rigorous process. The design dossier must clearly present fire detection and suppression systems, escape routes, water supply, lightning protection, safety distances, fire zones, and many other factors aligned with the factory’s production nature and materials. Any non-compliant element can result in required revisions, delaying the construction timeline.

The PCCC design approval is carried out by:

- The Department of Fire Prevention and Rescue (under the Ministry of Public Security): Handles large-scale, complex, or specially designated projects.

- Provincial Fire Police Departments: Handle standard projects at the local level.

These authorities not only approve or reject fire protection designs but also conduct final inspections after construction and may impose penalties or suspend operations for non-compliance.

- Protect lives and assets: A compliant design minimizes damage in case of fire and ensures effective evacuation routes for workers.

- Prevent legal and financial risks: Non-compliant systems may require dismantling or redesign, leading to costly delays or suspensions.

- Ensure legal compliance: Approval is a prerequisite for construction permits and lawful operation.

- Support coordinated design and construction: Early approval enables all involved parties to align their technical plans, avoiding costly reworks.

According to Decree 136/2020/NĐ-CP issued by the Government on November 24, 2020, and its guiding documents, all projects with fire/explosion risks or those accommodating crowds must undergo fire protection design approval before construction. Industrial factories are specifically regulated due to high fire risk.

As per Appendix V – Decree 136/2020/NĐ-CP, the following must undergo PCCC design approval:

- Factories and warehouses with a volume of 5,000 m³ or more

- Facilities involving flammable or explosive production:

+ Chemical, petroleum, gas, paint, solvent production/storage

+ Plastics, rubber, paper, textiles

+ Mechanical works with sparks, welding, industrial grease

- Factories with automated, enclosed production lines that are difficult to control in emergencies

- Facilities with two or more floors, residential or office space, or cold storage

Note: Even small-scale facilities with high fire risk must undergo approval based on their risk profile, not just volume.

Authorities assess two main factors:

(a) Construction scale

< 5,000 m³: Not mandatory (unless fire risks exist)

≥ 5,000 m³: Mandatory approval required

(b) Fire hazard level

- Very high (Class A): Fuels, chemicals, gases, explosives

- High (Class B): Solvents, paint, rubber, textiles, cold storage

- Medium-Low (C, D, E): Dry food, wood, packaging, metals

The higher the hazard class, the stricter the approval, especially for escape routes, alarms, and automated suppression.

Per Article 15, Decree 136/2020/NĐ-CP, exemptions apply to:

- Warehouses < 5,000 m³ with no fire-prone materials

- Minor renovations not affecting structure, use, or fire system

- Temporary prefabricated structures with no regular occupants

- Projects under special agencies with independent fire protection systems

Note: Exempted projects may still require fire system inspection prior to operation under Article 17.

When conceptualizing factory design, investors should:

- Verify whether the project requires PCCC approval

- Optimize layout and technical plans early on

- Avoid rework and shorten construction permit timelines

Each regulated factory must follow a four-step design approval process:

Designs must be prepared by qualified units as per Circular 148/2020/TT-BCA. The dossier includes:

- Application form (Appendix I – Decree 136)

- System drawings: alarms, extinguishers, escape plans, external water sources

- Technical report: risk analysis, design explanation

- Legal documents: investor licenses, designer certifications

To avoid redesign, involve your factory design unit early for coordinated planning.

Submit to:

- Department of Fire Prevention – Ministry of Public Security for large/national projects

- Provincial Fire Police for standard local projects

Submissions can be made in person or online for efficiency and progress tracking.

Authorities will:

- Compare designs with QCVN 06:2022/BXD, 06A:2022/BXD, TCVN standards

- Assess escape systems, alarms, suppression setup

- Issue revision requests (if needed) within legal timeframes

Incomplete or incorrect dossiers are suspended until resolved.

Once compliant, an official approval letter is issued—this is not a final inspection, but the prerequisite for a construction permit.

Processing Time (Article 13 – Decree 136/2020/NĐ-CP)

|

Project Type |

Max Processing Time |

|

Small (<5,000 m³) |

5 working days |

|

Medium (2 floors, PCCC system) |

10 working days |

|

Large/High-Risk |

15 working days |

|

Revised Submission |

Recalculated upon resubmission |

In practice, timelines may extend if documents lack technical consistency. Early collaboration with your factory and PCCC design teams will reduce delays.

Based on experience with police agencies, BIC recommends submitting four document groups:

|

Group |

Detailed Components |

Expert Note |

|

1. Fire protection design drawings |

Fire zone layout, safety distances, fire alarm and suppression system drawings, emergency lighting, external water supply |

Scale 1/100–1/200, show pipe diameters, pressure, widths ≥ 1.1m |

|

2. Technical explanation |

Production line details, risk calculations, sprinkler coverage, smoke pressure systems, escape time calculation |

Follow QCVN 06:2022/BXD, TCVN 3890, 7336; include simulations and certifications |

|

3. Legal documents |

Application form, business/investment licenses, designer certifications |

Consistency across all documents |

|

4. Special compliance (e.g., GMP, ISO) |

Clean/contaminated zoning, cleanroom pressure, flame-retardant materials, static prevention, chemical ventilation |

Required for pharmaceutical, food, cold storage, chemical facilities |

Proper preparation reduces 30–40% approval time and avoids costly redesigns.

Many delays stem from working with inexperienced or unqualified contractors. To avoid this:

As per Circular 148/2020/TT-BCA:

- Must have design/construction capacity certificate (from Ministry of Public Security or DOLISA)

- Licensed PCCC engineers

- Independent equipment testing certificates for systems, sensors, extinguishers

Avoid providers who outsource signatures without genuine expertise.

Good contractors will:

- Propose optimal solutions for your facility (foam, gas, sprinkler systems)

- Liaise with authorities and handle approvals

- Coordinate across architecture, structure, and MEP teams

- Assist with final inspections and resolve post-construction issues

PCCC systems can account for 8–15% of total factory costs. Cost-saving tips:

- Optimize sprinkler head count and zoning

- Use compliant but non-premium imported equipment (EN/UL/FM certified)

- Reuse existing water pressure systems if feasible

- Design compact evacuation routes using fire doors and shared staircases

Many cost overruns stem from poor design, not high technical standards. Choosing the right contractor ensures legal compliance, efficient construction, and long-term operational safety.

Contact BIC for expert consultation on industrial factory fire protection system design and approval