Investing in an industrial park is a strategic decision that requires careful planning from the very beginning. A smart choice isn't solely based on location or attractive land lease prices, it also hinges on a comprehensive evaluation of legal factors, infrastructure, policy incentives, and long-term production potential.

In particular, the design construction of the factory must be prioritized from the outset, as it directly affects operational efficiency, investment costs, and scalability in the future. In this article, BIC highlights the five most important factors investors should consider before choosing an industrial park to lay a solid foundation for their factory projects.

The location of the industrial park is a decisive factor in the success of any manufacturing project. A well-positioned site allows businesses to optimize logistics costs, shorten delivery times, and ensure a smooth supply chain.

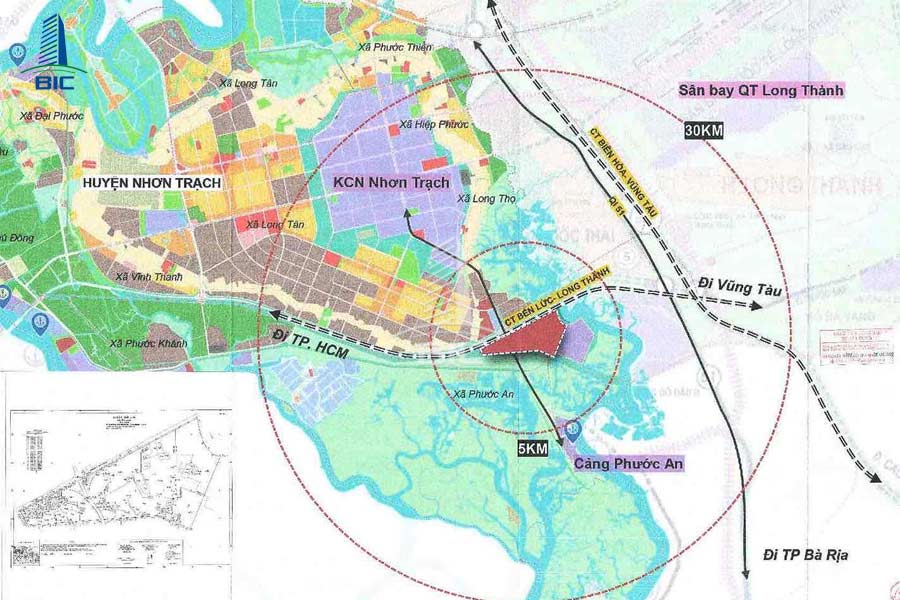

Industrial parks located near international seaports, airports, expressways, and logistics hubs strongly support import-export activities especially for FDI enterprises or industries with high transportation volumes. In addition, internal road systems and regional connections should be well-developed to support heavy loads and facilitate the movement of materials and finished goods.

For companies planning to build factories within industrial zones, choosing a strategic location not only helps reduce operating costs but also creates favorable conditions for future expansion. Therefore, location should not be seen as a temporary advantage but rather a long-term strategic asset of the entire project.

Legal clarity is the foundation of any safe investment decision. Before signing any agreements, investors must verify all legal documents of the industrial park, such as the establishment decision, land use rights certificate (red book), 1/500 detailed master plan, and other approvals from competent authorities.

Investing in a park with incomplete legal status carries risks such as project delays, land disputes, inability to obtain construction permits, or even potential revocation of investment licenses. These mistakes not only delay project timelines but can also cause significant financial and reputational damage.

In parallel, the industrial park’s master planning should be carefully assessed. A well-planned zone ensures synchronization across key components: internal roads, water supply and drainage, power supply, wastewater treatment, green spaces, and supporting infrastructure. This is a prerequisite for smoothly and properly executing the factory design and construction.

Choosing a park with complete legal documentation, clear planning, and well-developed infrastructure is a smart move to ensure legal compliance, timely execution, and long-term operational success.

Land lease prices are often the primary consideration for businesses when evaluating industrial park investments. However, it’s the total operating cost that determines a project’s long-term sustainability. A low land lease rate paired with high operating costs, poor infrastructure, or unclear support services can end up costing the business more in the long run.

Before signing a lease agreement, investors should request transparency on all associated costs, including:

- Land lease rate per square meter and lease term (typically 30–50 years);

- Internal infrastructure maintenance fees;

- Industrial electricity, water, and wastewater treatment costs;

- Management, security, fire protection, and other support service fees.

Additionally, investors should clarify terms regarding periodic price adjustments and potential hidden costs that could impact long-term budgeting.

It’s crucial that these costs be factored into the factory’s design and construction plans from the start. Design should go beyond functionality and aesthetics, it must also incorporate energy-efficient solutions, appropriate materials, and operational optimization to help businesses control costs and increase profitability.

Smart financial planning from the outset helps companies avoid hidden costs and maintain stable operations throughout the project lifecycle.

Besides location, legal transparency, and cost, investment incentive policies play a key role in optimizing expenses and accelerating project execution. For manufacturing companies in particular, enjoying tax incentives and streamlined administrative procedures can shorten the time to market and boost competitiveness.

Many provinces and cities offer diverse incentive programs, including:

- Corporate income tax exemption for the first 2–4 years, with a 50% reduction for the following 5–9 years;

- Land rent exemption or infrastructure support for priority projects;

- Fast-tracked licensing for investment, construction, environmental approval, and fire safety via a "one-stop" mechanism.

For foreign investors, the support of the Industrial Park Management Board or local Investment Promotion Centers is crucial in overcoming administrative challenges and ensuring timely project implementation.

Taking full advantage of available investment incentives not only reduces initial costs but also improves net profits during the early stages of operation often the most financially challenging period.

Pro tip: Choose industrial parks with clearly defined investment policies, backed by local government support and dedicated investor assistance from the pre-feasibility phase.

An industrial park should offer more than just vacant land and technical infrastructure—it must have a complete manufacturing ecosystem. All elements of the supply chain, logistics services, and labor force should be readily available to support seamless business operations.

When choosing a site, businesses should prioritize parks with established production communities, ideally featuring companies from the same industry or supporting sectors. This simplifies sourcing of materials and components while optimizing logistics by leveraging an internal value chain.

A robust ecosystem also includes:

- Logistics centers, warehouses, industrial gas stations;

- Worker dormitories and expert housing;

- On-site medical clinics, vocational schools, administrative services;

- Complete systems for wastewater treatment, clean water supply, and fire protection.

Local labor availability is another strategic consideration. Industrial parks near residential areas, vocational schools, or technical colleges make it easier to recruit a stable workforce, minimizing training time especially in skilled or semi-skilled industries.

All these factors are foundational for building efficient factories and ensuring long-term operational success. A good industrial park supports not just the start-up phase but also long-term growth and sustainable development.

Many industrial park investments fail not due to lack of capital or market demand, but because of underestimating the importance of initial design. A poorly planned factory design can lead to cost overruns, construction delays, or even the need for post-operational renovations.

Factory design isn’t just about erecting a solid structure it must meet a wide range of technical standards:

- Suitability for specific manufacturing industries;

- Efficient land use within the industrial zone;

- Full compliance with regulations for fire safety, structural integrity, environmental protection, operations, and labor safety.

That’s why choosing a professional design consultancy is a prerequisite. An experienced team familiar with industrial parks can help businesses:

- Optimize functional layouts;

- Plan electrical, water, ventilation, and internal traffic systems;

- Align the design with park-specific technical standards;

- Streamline permitting, approval, and construction processes.

Turnkey design build solutions are increasingly popular for their consistency, cost control, and avoidance of contractor conflicts. Investors should work with consultants early during site selection to conduct surveys, determine workshop scale, and build realistic investment budgets.

Are you preparing to invest in an industrial park and seeking a professional, efficient, and cost-effective factory design solution? Don’t let poorly informed decisions lead to delays or budget overruns.

Contact BIC’s engineering team today to:

- Receive free consultation on a tailored factory design that fits your production needs and site conditions;

- Conduct on-site surveys based on your investment goals;

- Get a clear, detailed quote that aligns with your actual usage requirements.

BIC is your trusted partner from concept and design to construction and operation ensuring compliance with technical standards, legal requirements, and project timelines.