Industrial factories play a central role in production activities, serving as hubs for machinery, manpower, and operating lines. To maximize efficiency, the design stage from the outset is of decisive importance. Among modern approaches, the trend of using pre-engineered steel frames is gradually replacing the traditional reinforced concrete model thanks to outstanding advantages in cost, schedule, and expandability.

Steel frame factory design not only provides flexibility in space layout but also helps businesses optimize investment budgets. Steel components are manufactured synchronously at the factory, then transported to the construction site for assembly, ensuring quality control and significantly shortening construction time. In particular, steel structures are lightweight yet highly durable, meeting strict safety standards in heavy industrial production environments.

Besides technical factors, a standard factory design process must also ensure proper ventilation, lighting, fire protection, and aesthetics. As a result, the factory is not only sustainable but also creates a favorable working environment, contributing to increased labor productivity. With its outstanding advantages, steel frame factories are becoming a strategic choice for many businesses in Vietnam as well as worldwide.

To achieve a steel frame factory project that ensures technical standards while optimizing costs, adhering to a structured design process is indispensable. From surveying, drafting blueprints, fabricating components to assembly and warranty, every step must be carried out carefully and precisely. In the following section, BIC will present in detail the standard steel frame factory design process, helping investors gain a clear understanding before implementing their projects.

The steel frame factory design process is built on principles of safety, functionality, and cost-effectiveness. This stage is crucial in determining operational efficiency later on and should therefore follow specific steps:

The first step is surveying the site conditions to assess geology, topography, and infrastructure. At the same time, the design unit collects information from the investor regarding production type, number of machines, warehouse requirements, and industry-specific needs. Based on this data, architects propose preliminary design concepts, defining functionality and suitable spatial layouts.

Once the concept is agreed upon, engineers develop technical drawings. These include steel frame structural plans, functional floor layouts, electrical – water systems, lighting, ventilation, fire protection, and details related to loads. Detailed calculations ensure safe operation, minimize technical risks, and reduce additional costs.

Main components such as columns, trusses, beams, and purlins are pre-manufactured at the factory. The fabrication process typically involves strict steps: steel cutting, automatic welding, surface cleaning, metal spraying, anti-rust painting, or galvanizing. As a result, the components achieve high durability, corrosion resistance, and long service life.

After fabrication, all components are packaged and transported to the site. The erection process strictly follows design drawings and safety standards. Engineers supervise continuously to ensure each detail is installed accurately, from bolt connections and welds to roof structures and enclosures.

Once construction is complete, the contractor and investor conduct acceptance checks. Each item is carefully inspected for structural stability, fire protection, lighting, and waterproofing. In addition, most reputable design units provide long-term warranties for steel structures and roofing systems, ensuring peace of mind for investors during use.

A standard steel frame factory is evaluated not only for structural durability but also for functionality, safety, and aesthetics. To ensure long-term quality, the design process must comply with the following key standards:

Industrial factories house heavy machinery, cranes, and frequent cargo movements with large loads. Therefore, the steel frame must be carefully calculated to transfer forces evenly to the foundation. The foundation must be strong enough to prevent settlement or cracking, ensuring stability throughout the building’s lifespan.

Since factories concentrate a large workforce and equipment, proper natural and mechanical ventilation is essential. Roof designs with louvers, windows, openings, combined with insulating and soundproofing materials, help create a cool working space, reduce energy consumption, and protect workers’ health.

A standard factory must have wide space, convenient for machine installation, material movement, and production line layout. Designs should also account for future functional changes, allowing businesses to expand easily when demand increases.

In industrial production environments, fire risks are always present. Steel frame factories must use fire-resistant materials and apply surface treatments such as fireproof coatings, galvanizing, or protective layers to resist corrosion. This is an important standard to extend service life and reduce maintenance costs.

A key advantage of steel frames is easy expansion when businesses need to increase production capacity. Adding new frames, columns, and supplementary structures can be done quickly without disrupting ongoing operations, unlike traditional concrete buildings.

A good factory is not only durable but also aesthetically pleasing. Modern exterior design, harmonious paint colors, combined with green spaces and natural lighting systems, create a comfortable working environment while enhancing the company’s brand image.

Steel frame factories are now widely applied across many production fields due to their flexibility and investment efficiency. Depending on land area, production type, and usage needs, steel frame factories are commonly divided into the following types:

This is the most widely used type today, especially in large industrial parks and factories. Single-story factories usually range from several hundred to tens of thousands of square meters, suitable for heavy industries with cranes or large-scale production lines.

- Advantages: Spacious, convenient for machine arrangement and goods movement; easy horizontal expansion.

- Applications: Mechanical manufacturing, woodworking, textiles, logistics, and warehousing.

Amid increasingly limited land resources, multi-story factories are becoming a new trend, especially in industrial zones near major cities. This model combines production space with office areas in the same building, optimizing land use.

- Advantages: Saves land, integrates multiple functions conveniently, easy production management and supervision.

- Applications: Light industries, high-tech, electronics, and garment production.

Besides the two common types above, there are also specialized steel frame factories such as:

- Cold storage factories: For food, seafood, pharmaceuticals, requiring strict insulation and preservation systems.

- Logistics warehouses: Integrated with racking systems, loading and unloading areas, and flexible transportation.

- Livestock farming factories: Serving high-tech agriculture and large-scale farming, ensuring ventilation and environmental hygiene.

This diversity in design enables steel frame factories to flexibly meet the needs of many industries, from traditional production to modern technology sectors.

Steel frame factories are increasingly popular due to their superior characteristics compared to traditional reinforced concrete models. They not only meet technical requirements but also deliver economic efficiency and high flexibility for businesses. Key advantages include:

Steel frames are designed with high load-bearing capacity, ensuring safety for heavy production activities. Compared to reinforced concrete, steel structures are significantly lighter, reducing foundation pressure and saving construction costs. Using high-quality steel also ensures long-lasting durability and resistance to harsh weather conditions.

Steel components are manufactured synchronously at the factory and only need to be transported to the site for assembly. This process greatly shortens construction time, typically lasting only 3 to 6 months depending on scale. As a result, investors can quickly put the factory into operation, optimizing capital turnover.

Steel frame factories reduce costs in many stages: materials, labor, and foundations. Shortened construction time also means project management and operation costs are significantly reduced. In addition, thanks to high durability and corrosion resistance, the project generates minimal maintenance costs during use.

Another outstanding advantage is the ease of expansion. When businesses need more production space, adding steel frames or columns can be done quickly without affecting current operations. At the same time, steel frame factory designs allow space customization for various purposes such as storage, production lines, or office areas.

Using recycled steel in component production helps reduce environmental impact. Moreover, modern design combined with natural lighting, ventilation, and green spaces contributes to a sustainable working environment and enhances corporate image.

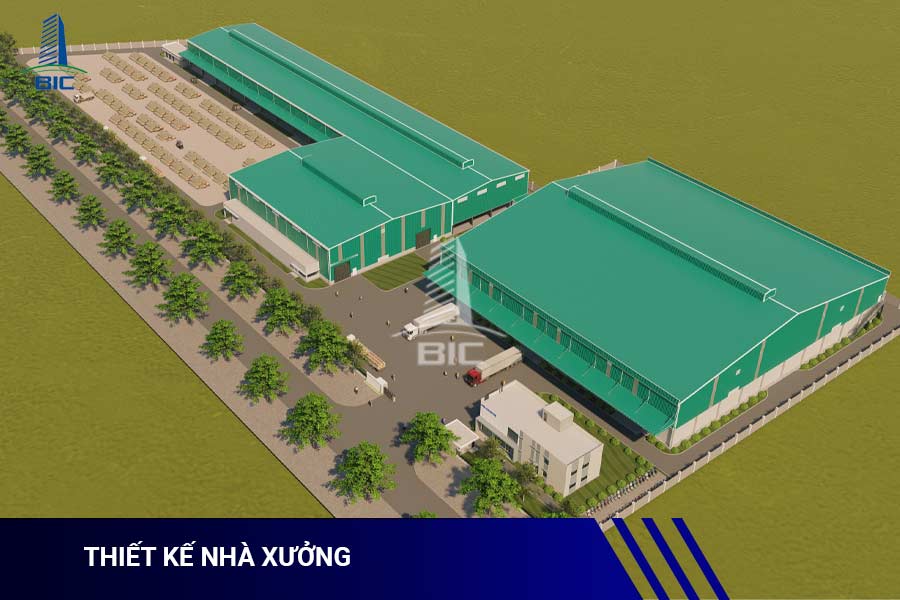

The development of construction technology enables today’s steel frame factories to ensure not only durability but also aesthetics and multifunctionality. Below are some typical design models favored by many businesses:

This design suits wide industrial zones requiring large production areas. Green spaces arranged around or inside the factory improve microclimate, create a friendly working environment, and minimize environmental impact.

This trend is popular among businesses in industrial zones near cities where land is limited. It combines production areas with management offices, optimizing space and facilitating operations.

Specialized designs for food, seafood, and pharmaceuticals. These buildings are equipped with advanced insulation, cooling, and preservation systems to maintain product quality under strict conditions.

With solid steel structures and flexible space, this model meets storage, loading, and transportation needs. Designs often integrate rolling doors, container yards, and convenient import-export zones.

Beyond industry, steel frames are also applied in agriculture. Steel-frame barns or greenhouses help control microclimates, increase productivity, and meet biosecurity requirements.

These design models demonstrate the flexibility and wide applicability of steel frame factories, giving businesses multiple options suitable for their scale and industry characteristics.

Steel frame factory design is becoming the top choice thanks to its superior advantages in durability, cost, and flexible expansion. A structured design process that fully meets technical standards will provide businesses with facilities that are both safe and optimized for long-term production efficiency. From large-scale factories, multi-story facilities to cold storage and logistics, steel frame structures can adapt flexibly to practical needs.

If you are seeking a modern, sustainable, and cost-effective factory design solution, contact our team of experts today for detailed consultation and a suitable quotation. A proper design from the outset is the key to helping businesses optimize investment and enhance competitiveness.

Contact BIC today for professional steel frame factory design consultation, the optimal solution for your project.