Ensuring fire and explosion safety in factory design is of paramount importance. Fire protection systems (FPS) not only help safeguard assets and human lives but are also crucial for compliance with legal regulations and risk mitigation. In this article, BIC will explore the details of FPS in factory design and the benefits these systems bring. Understanding and properly implementing fire safety standards will help your business create a safe and sustainable working environment.

Many small factories only need to meet standard fire safety regulations without requiring a detailed FPS design and approval. However, for factories with a volume of 3,000 m³ or more, FPS design approval is mandatory according to Appendix V - List of projects, works, and motor vehicles subject to FPS design approval issued with Decree 136/2020/NĐ-CP.

According to Clause 4, Article 13 of Decree 136/2020/NĐ-CP, the dossier for requesting FPS design approval includes:

- Request Document: The investor must submit a document requesting the review and opinion on fire protection solutions. If authorized, a valid authorization document must be attached.

- Investment Policy Approval Decision: For factories using public investment capital, this decision must be approved and submitted with the dossier.

- Investment Policy Acceptance/Investment Registration Certificate: For factories using other sources of capital, a document of investment policy acceptance or an investment registration certificate (if any), a land use right certificate, or a document proving legal land use rights must be submitted.

- Fire Safety Business Certification: From the design unit and a basic design explanation showing fire protection solutions. This ensures that the design unit meets the business conditions in the fire protection field.

Complying with these regulations not only ensures fire safety for the factory but also ensures that the business adheres to the law, avoiding unnecessary risks and damages in case of fire incidents. These steps should be performed by experts and highly specialized units to ensure accuracy and effectiveness.

The installation of FPS in factory design must strictly comply with the standards and regulations of Vietnamese law, specifically:

Fire Protection Design Standards:

- TCVN 2622 – 1995: Fire prevention and protection for buildings and structures – Design requirements.

- TCVN 5738 – 2001: Fire alarm systems – Detailed technical drawing requirements.

- TCVN 3890 – 2009: Provisions on equipment and basic requirements related to arrangement, inspection, and maintenance of fire protection equipment for factory buildings.

- TCVN 5760 – 2001: Fire extinguishing systems – General requirements for detailed factory design, installation, and use of FPS.

- TCVN 4513 – 88: Water supply for FPS – Design standards.

- TCVN 3526 – 89: Fire safety – General requirements for FPS.

Fire Protection Design Regulations:

- QCVN 06: 2010/BXD: “National Technical Regulation on Fire Safety for Buildings and Structures”

- QCVN 08: 2009/BXD: National technical regulation for urban underground works.

The FPS in factory design, when designed to standard, will include the following components:

- Fire Alarm System: Includes smoke detectors and heat detectors. Smoke detectors identify smoke and send signals to the fire alarm control panel to activate the alarm function. Heat detectors send signals to the fire alarm control panel when the temperature exceeds the permissible limit, providing timely fire warnings.

- Alarm and Notification System: This system notifies all personnel in the factory area of the fire situation. Additionally, it can directly contact the fire police and fire protection forces to ensure timely and effective fire response.

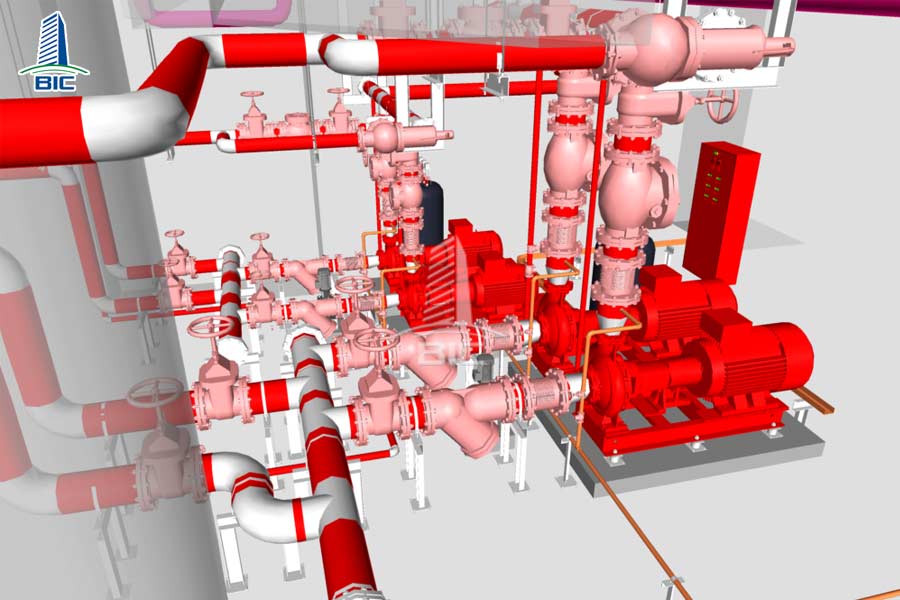

- Fire Extinguishing System Design and Installation in Factory Design: Includes installing various fire extinguishing systems such as Sprinkler systems, dry chemical systems, CO2 gas systems, and Foam systems. These systems are selected and installed according to the specific characteristics and needs of the factory, ensuring the ability to extinguish fires quickly and safely.

According to Clause 1, Article 5 of Decree 136/2020/NĐ-CP, factory design must meet the following fire safety conditions:

- Regulations and Guidelines: Factories must have fire safety rules, signs, prohibition signs, fire escape diagrams or guidance signs that comply with fire safety standards or regulations of the Ministry of Public Security.

- On-site Fire Protection Forces: Factories need to have on-site or specialized fire protection forces corresponding to the type of activity, trained in fire safety and always ready to extinguish fires on-site.

- Firefighting Plan: A firefighting plan approved by the competent authority is required.

- Electrical and Fire Safety: Electrical systems, anti-static, lightning protection, electrical devices, heat-generating, and fire-generating equipment must ensure fire safety according to standards or regulations of the Ministry of Public Security.

- Supporting Infrastructure: Factory design needs to include traffic systems, communication systems for firefighting, water supply systems, fire safety database management systems, fire alarm systems, fire extinguishing systems, fire prevention systems, smoke control, and escape systems, along with other fire protection and rescue equipment, ensuring quantity and quality according to standards or regulations of the Ministry of Public Security.

- Legal Documentation: Factories must have fire safety design approval certificates, design approval documents (if any), and acceptance documents of fire safety results from the fire police department.

These conditions help ensure that factories are always in a fire-safe state, protecting workers and business assets.

For the design of steel frame roof factories with areas exceeding the fire compartment, the following conditions must be met:

- Fire Spread Prevention Solutions: Implement measures to prevent and limit the spread of fire. These may include using special building structures such as fire walls, fire doors, and fire-resistant coatings on material surfaces. Additionally, FPS like automatic sprinkler systems, foam systems, or CO2 gas systems can be used to control fires and prevent the spread of flames.

- Increasing Fire Resistance of Main Building Components: To ensure that the main building components can withstand high temperatures for an extended period without collapsing, solutions to increase fire resistance must be implemented. This can be done using fire-resistant materials or fire protection methods for steel components, such as fireproof paint, fire-resistant coatings, or special insulation layers. These solutions must comply with fire protection standards and technical regulations, ensuring that building components maintain integrity and load-bearing capacity throughout the fire, thereby reducing the risk of collapse and protecting the safety of workers and assets in the factory.

Fully implementing these measures not only ensures fire safety for the factory but also helps businesses comply with legal regulations, reducing risks and damages when fire incidents occur. These solutions need to be designed and constructed by highly specialized units to ensure the effectiveness and reliability of the FPS.

The causes of fire and explosion in factories are diverse and can be listed as follows:

- Flammable Materials: Factories often contain many materials such as paper, wood, fabric, grease, and other flammable materials. When exposed to high heat sources, these materials can quickly ignite and spread.

- Chemical Raw Materials and Products: Substances like oil, gasoline, flammable liquids, or oxidizing agents can easily cause fires and explosions when not stored or used properly.

- Electrical Systems: Unsafe electrical systems, overloaded electrical equipment, or damaged and broken wires can create sparks and cause fires.

- Equipment and Machinery: Devices such as engines, pumps, fuel systems, compressors,... if damaged or have technical faults, can also cause fires and explosions.

- Metal Welding and Cutting: These activities generate high temperatures and sparks, which, if safety measures like using fire-resistant materials and protective equipment are not followed, can lead to fires and explosions.

- Human Error: Actions like smoking, using open flames, carelessness, and non-compliance with fire safety rules can also cause fires and explosions in factories.

These causes need to be monitored and controlled by factory managers and employees to ensure the safety of assets and human lives.

Fire protection systems (FPS) play a crucial role in protecting factories from fire and explosion risks. By providing warning devices, alarm systems, and effective firefighting solutions, FPS not only help minimize asset damage but also ensure the safety of employees and the working environment. Especially for large-scale and high-risk factories, designing and implementing FPS according to standards and regulations is indispensable.

Let's take action now to ensure that every factory's FPS meets the highest safety requirements. Contact fire protection experts for consultation and support in designing effective systems, thereby safeguarding not only assets but also the lives of everyone in the industrial production environment.