The demand for factory design has been increasing strongly as many businesses have expanded their production scale in recent years due to the continuous growth of the economy. A standardized, professional design not only determines the functionality and lifespan of the building but also helps optimize investment and long-term operating costs.

In addition, choosing a reputable design and construction unit with a transparent pricing list is always a key factor to ensure economic efficiency. Currently, design costs vary depending on the area, type of structure, and complexity of each project.

In this article, BIC will update the latest pricing, while providing important information to help businesses choose the most suitable factory construction solution according to their budget and actual needs.

Factory design is the starting point that plays a decisive role throughout the entire lifecycle of a construction project. It involves calculations, planning, and detailed drawings to ensure the building meets both production needs and technical requirements.

A well-prepared design not only lays the groundwork for smooth construction but also directly impacts operational efficiency and long-term costs.

Benefits of a Standardized Factory Design:

- Optimized production space: Scientifically arranged layout, reasonable production lines, streamlined logistics for goods and personnel.

- Cost savings in investment and operation: Minimizes unexpected issues, reduces construction errors, while saving energy and maintenance costs.

- Safety and sustainability: Designed according to technical standards, meeting fire protection requirements, load capacity, and structural durability.

- Future expandability: Flexible design allows easy adjustments or expansion when production scale increases.

From these factors, it is clear that a high-quality factory design is the “key” for businesses to both optimize costs and ensure long-term efficiency.

During the design and construction process, complying with fundamental principles is essential to ensure technical standards, safety, and long-term usability.

The design must fully meet the requirements of the Ministry of Construction and current Vietnamese standards. For example, TCVN 2737:1995 regulates loads, geological conditions, and hydrology to ensure structural safety, preventing subsidence or damage.

Escape routes, fire exits, signage, and fire-fighting equipment must be properly arranged. Ventilation, lighting, electrical, and water systems must be safe and meet industrial operation standards.

Production layouts must be scientific, convenient for the movement of materials, products, and staff. Factory space should be flexible to suit specific production lines.

In addition to functionality, the factory design should ensure neat, modern architecture. Sustainable materials should be used, with energy-saving and eco-friendly solutions applied.

Design must include provisions for expansion or auxiliary works. This flexibility allows easy renovation or upgrades, saving costs when business scale changes.

These principles are the backbone to ensure a factory project achieves maximum efficiency in terms of cost, functionality, and durability.

A factory design dossier is not only a legal requirement for obtaining construction permits but also the foundation that ensures accurate execution, minimizes errors, and saves costs. When the dossier is detailed and complete, the investor can control the entire project from design and construction to long-term operation.

This plan illustrates the overall layout of the project on the land, including production areas, warehouses, offices, and supporting facilities. It allows businesses to easily assess land use efficiency and facilitates the process of obtaining construction permits.

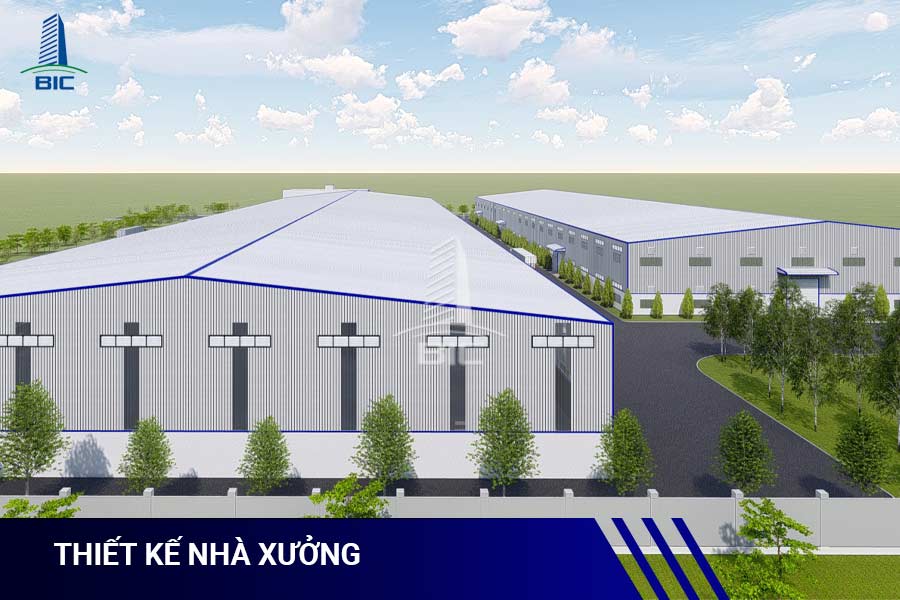

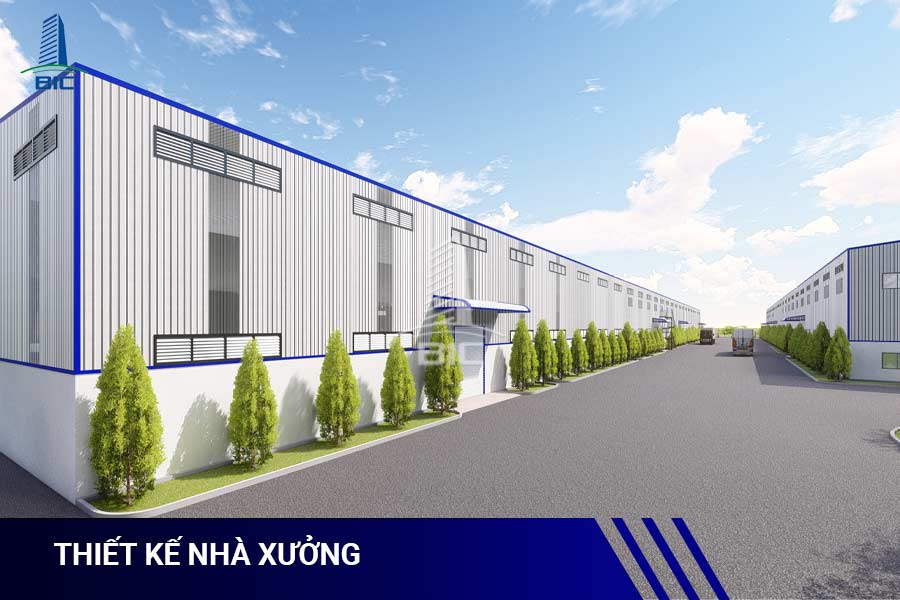

3D renderings provide a visual representation of the factory’s architecture, allowing evaluation of aesthetics and harmony with the surrounding environment before construction begins. These drawings are also essential documents for investors to approve the design plan.

This section includes floor plans, sections, and elevations of the building. Architectural drawings clarify usable space, height, and area of each section, ensuring rational arrangements for production activities.

The structural dossier provides detailed drawings of foundations, columns, beams, floors, roofs, and steel frames. This is a decisive factor in the durability, load-bearing capacity, and lifespan of the factory.

This includes electrical systems, water supply and drainage, lighting, ventilation, fire protection, and wastewater treatment. These ensure that the factory operates safely, meeting technical standards and environmental regulations.

This section helps investors clearly understand the costs for each part of the project, from materials and labor to construction methods. At the same time, technical explanations provide the basis for assessing feasibility and calculating investment efficiency.

A factory design dossier is the foundation for the entire process of factory design and construction. The more detailed the dossier, the better the project will ensure quality, safety, and cost efficiency for businesses.

Depending on scale, functionality, and construction materials, industrial factories can be designed in various ways. Each design model offers distinct advantages, suitable for the specific production characteristics and investment budgets of different businesses.

The two most common materials today are pre-engineered steel and reinforced concrete.

- Pre-engineered steel factories: Advantage of fast construction, reasonable cost, and easy expandability, suitable for industries such as mechanics, garments, and electronics.

- Reinforced concrete factories: Durable, with good sound and heat insulation, suitable for projects requiring high stability such as multi-story warehouses, food, or pharmaceutical plants.

Each industry has its own characteristics, so floor layouts and production spaces differ accordingly.

- Production factories: Spacious, well-ventilated, with layouts optimized for production efficiency.

- Warehouses/cold storage: Focused on storage capacity, insulation, and temperature control systems.

- Food and pharmaceutical plants: Must meet hygiene and safety standards, equipped with strict environmental treatment systems.

Factory height usually ranges from 6m to 12m, depending on production needs and types of machinery used.

- 6m–8m height factories: Suitable for light industries, using medium and small machines.

- Above 10m height factories: Suitable for mechanical production, assembly, or storing large equipment.

Factory scale directly affects the design approach and investment costs.

- Small factories (1,000–3,000m²): Usually simple in design, cost-effective in construction.

- Medium factories (3,000–10,000m²): Require scientific layout balancing production and storage.

- Large factories (over 10,000m²): Demand detailed design and careful calculation to ensure safety and operational efficiency.

These design models provide a basis for businesses to choose the most suitable option for their industry and investment goals. A properly designed plan helps optimize costs, shorten construction time, and deliver long-term usage value.

During the factory design process, aside from following basic principles, investors must pay attention to practical factors to ensure maximum efficiency. The following notes will help businesses avoid mistakes and optimize costs from the very beginning of the design phase:

- Rational land zoning: Dividing land into production, storage, office, and supporting infrastructure areas is a critical first step. This arrangement ensures operational convenience, safety, and prevents overlap between activities.

- Scientific floor layout: The overall layout must allow smooth flow of production lines, raw materials, and goods. A well-organized design saves time, reduces operating costs, and increases productivity.

- Internal traffic planning: In factories, forklifts, small trucks, and workers often move simultaneously. Clearly planned internal traffic reduces collisions, improves efficiency, and ensures worker safety.

- Maximizing land use and building density: A good factory design should make the most of available land while calculating a reasonable construction density. This saves investment costs while meeting functional needs.

- Flexibility and scalability: Factories should be designed flexibly to allow adjustments or expansion in the future. This is crucial for businesses planning to scale up production.

- Lighting and ventilation solutions: Light and air are two factors that directly affect productivity and safety in factories. Designs should combine natural lighting with industrial systems, while ensuring proper ventilation or cooling.

By following these notes, investors and design units can create factories that not only meet technical standards but also deliver long-term efficiency and economic value.

Factory design costs are always a top concern for businesses before starting a project. Design prices vary depending on the area, type of structure, and complexity of the project. Below is a reference price list to help investors easily estimate their budgets.

Pre-engineered steel factories generally have lower design costs compared to reinforced concrete, while offering faster construction and greater flexibility for expansion.

|

Design Area |

Unit Price (VND/m²) |

|

1,000 – 2,000 m² |

24,000 VND/m² (reference) |

|

2,000 – 3,000 m² |

22,000 VND/m² (reference) |

|

3,000 – 5,000 m² |

20,000 VND/m² (reference) |

|

5,000 – 10,000 m² |

13,000 VND/m² (reference) |

|

10,000 – 100,000 m² |

10,000 VND/m² (reference) |

Reinforced concrete factories offer high durability, good sound and heat insulation, making them suitable for projects requiring long-term structural stability.

|

Design Area |

Unit Price (VND/m²) |

|

1,000 – 2,000 m² |

25,000 VND/m² (reference) |

|

2,000 – 3,000 m² |

23,000 VND/m² (reference) |

|

3,000 – 5,000 m² |

21,000 VND/m² (reference) |

|

5,000 – 10,000 m² |

14,000 VND/m² (reference) |

|

10,000 – 100,000 m² |

12,000 VND/m² (reference) |

- The above prices are for reference only. Actual costs may vary depending on technical requirements, construction location, and timing.

- Investors should contact design firms directly for detailed quotations tailored to their specific needs.

- In addition to design costs, businesses must also account for expenses such as construction permits, foundation works, fire protection systems, and environmental treatment.

By understanding this price list, businesses have a solid basis for comparison, enabling them to select a factory design solution that is both cost-effective and ensures construction quality.

To estimate design costs, investors need to clearly determine the type of factory structure and the total construction area. The basic formula is as follows:

Design cost = Area (m²) × Design unit price (VND/m²)

This method helps businesses easily forecast initial costs, balance their budget, and prepare before signing a contract with a design company.

A garment factory with an area of 4,500 m² chooses a pre-engineered steel structure with a design unit price of 20,000 VND/m².

- Design cost = 4,500 × 20,000 = 90,000,000 VND

Thus, the business only needs about 90 million VND for a detailed design dossier for the project.

A warehouse with 2 floors, each floor covering 1,800 m², uses reinforced concrete structure with a design unit price of 20,000 VND/m².

- Design cost = 1,800 × 2 × 20,000 = 72,000,000 VND

In this case, the design cost of the 2-story warehouse is about 72 million VND, which is reasonable compared to the durability and high technical requirements of such a solid structure.

- Unit prices vary depending on structure type, area, and project complexity.

- In addition to design costs, businesses should budget for geological surveys, construction permits, and specialized technical items such as cooling systems, wastewater treatment, or cleanrooms (if required).

- It is advisable to obtain quotations from multiple reputable design companies for objective comparison and optimal selection.

As shown, calculating design costs is not complicated but plays an essential role in investment planning. With accurate estimates, businesses can better control budgets and avoid risks during implementation.

Choosing a professional factory design company not only helps save costs but also ensures the project is built to standards, sustainable, and safe. In Ho Chi Minh City, BIC has become one of the trusted units for many businesses thanks to its extensive experience and comprehensive services.

BIC owns a team of experienced architects and engineers specialized in factory design and construction. With in-depth knowledge of industrial standards, the company always provides solutions tailored to the specific production requirements of each business.

One of the main reasons clients choose BIC is its clear and competitive factory design pricing. All costs are quoted transparently, enabling businesses to easily estimate and control their investment budgets.

The company undertakes a variety of factory projects, including:

- Pre-engineered steel factories

- Warehouses and production factories

- Food and pharmaceutical plants

- Mechanical and garment factories, as well as other specialized industries

Thanks to its flexibility, BIC can meet the diverse needs of businesses, from small-scale projects to those spanning tens of thousands of square meters.

In addition to design, BIC provides full-package construction services, including: building permits, foundation works, steel erection, fire protection systems, and environmental treatment. Project timelines are always guaranteed, helping businesses put their factories into operation quickly.

With its proven expertise, reputation, and comprehensive services, BIC is a reliable choice for businesses seeking affordable, high-quality, and efficient factory design solutions in Ho Chi Minh City.

A standardized factory design not only ensures effective functionality but also helps businesses optimize investment, operation costs, and future expansion. Understanding design principles, key considerations, and the latest design pricing enables investors to gain a comprehensive view and make more accurate decisions.

To achieve the best outcomes, businesses should select a reputable factory design and construction company with strong expertise and transparent pricing. This ensures a durable, safe project while saving significant costs.

If you are looking for an affordable, high-quality, and practical factory design solution, contact BIC today for consultation and a detailed quotation. This is the crucial step to creating a solid foundation for long-term business growth.