Factory design is the first and most crucial stage in an industrial construction project. It ensures the quality of the facility, operational efficiency, and compliance with legal regulations. During this process, technical drawings play an essential role not only helping visualize the entire project but also ensuring seamless coordination among components such as structural systems, technical installations, fire safety, and specific functional requirements.

So, what are the essential drawings included in a complete factory design? Let’s explore with BIC the must-have drawings that help optimize space and enhance production efficiency.

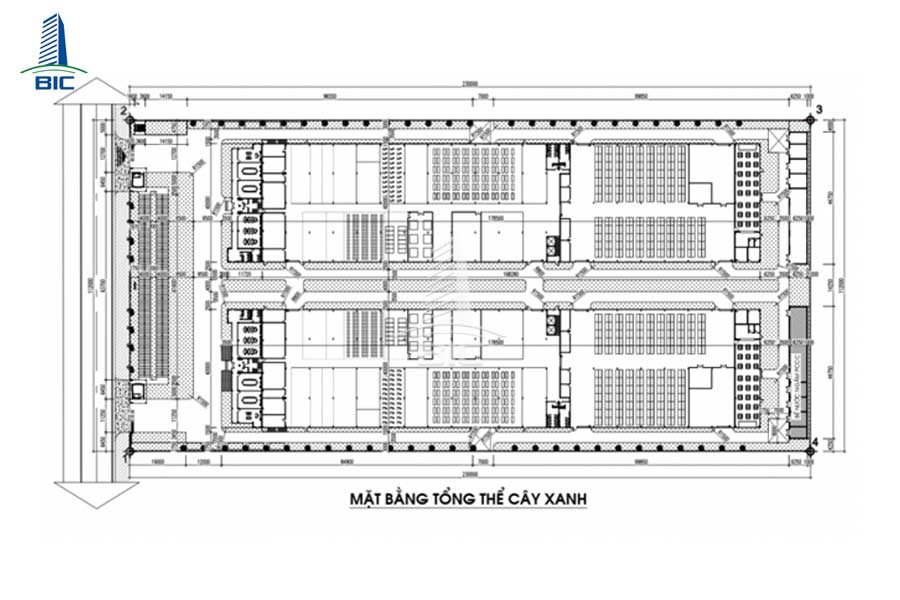

The site plan illustrates the factory’s location on the land plot and shows the arrangement of functional areas and external elements such as traffic routes, landscaping, and infrastructure. This is the first drawing in the factory design process and serves to shape the spatial layout and optimize the placement of structures on the land.

- Access points: Locations of main entrances and pathways to production areas, offices, and warehouses.

- Internal traffic: Roadways and pathways within the site for efficient transportation of goods and personnel.

- Auxiliary zones: Supporting structures such as parking areas, restrooms, break areas for workers, and water supply and drainage systems.

- Green spaces: Placement and density of trees, landscaped zones, and gardens to create a pleasant working environment and promote environmental sustainability.

- Infrastructure: Elements such as electricity, water supply, stormwater drainage, waste treatment systems, and other supporting facilities.

The site plan allows investors and stakeholders to clearly understand the overall layout of the factory. It forms the foundation for the functional zoning, ensures smooth traffic flow, optimizes space utilization, and minimizes construction risks. It also provides the basis for developing more detailed technical drawings.

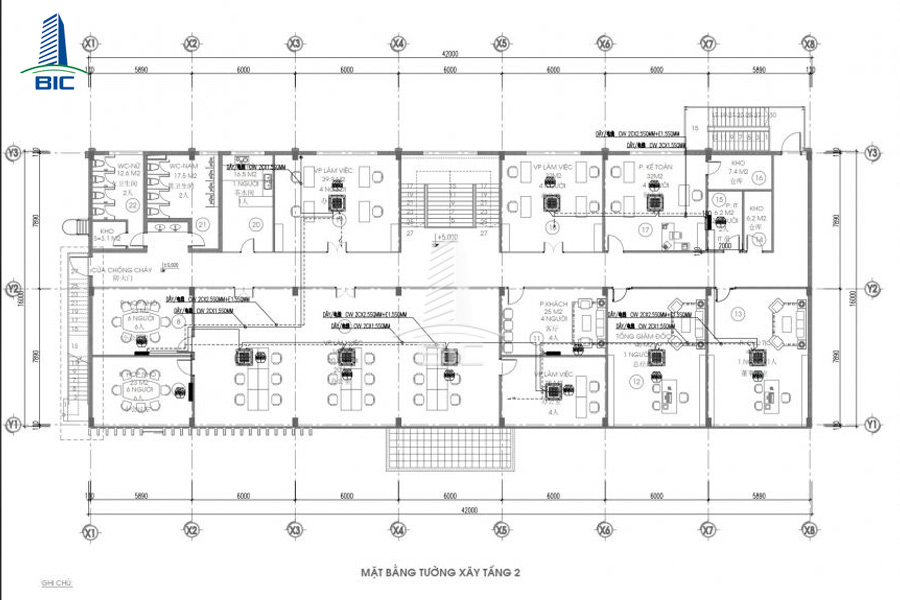

The floor plan illustrates the spatial layout and structure of different functional areas within the factory. It is crucial for determining how spaces are arranged and used efficiently, ensuring convenience in production and management.

- Production: The main zone for manufacturing, processing, and assembly activities. It may include production lines, quality control areas, and equipment maintenance zones.

- Storage: Areas for storing raw materials, supplies, and finished or semi-finished products. Special storage for cold goods, flammable materials, or chemicals must be clearly defined.

- Office: Workspace for management, technical staff, administration, and support departments. It should include offices, meeting rooms, reception areas, and supporting amenities.

- Sanitary Areas: Facilities for employee hygiene, including restrooms, showers, changing rooms, and other utilities.

- Auxiliary Zones: Such as worker break rooms, dining areas, technical rooms, maintenance zones, and other support spaces.

The floor plan ensures efficient functional use and space optimization. A scientifically and reasonably arranged layout enhances work efficiency, minimizes operating costs, ensures safety, and complies with workplace standards. It also facilitates equipment movement and workflow, reducing downtime and improving productivity.

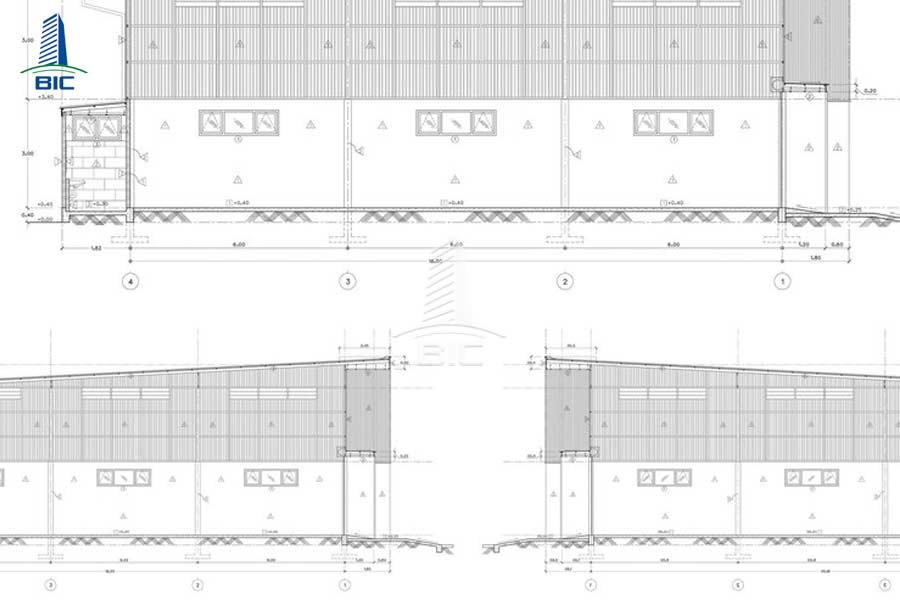

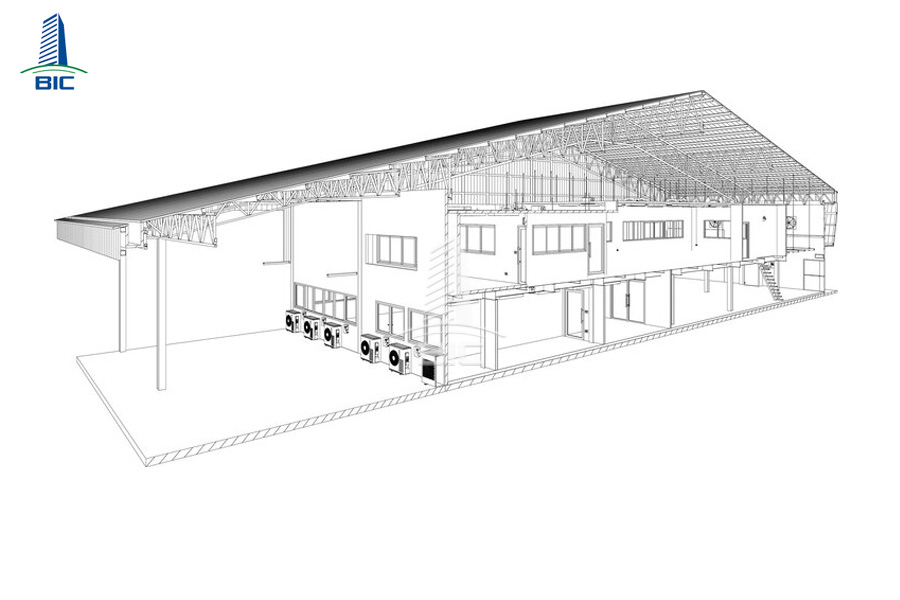

Architectural drawings detail the structural design of the factory, including the form, dimensions, materials used, and layout of building components. These drawings cover both exterior and interior design, ensuring that the factory is both functional and aesthetically sustainable.

- Roof: The roof must be designed for durability and load-bearing capacity, suitable for weather conditions such as rain and sun. Common roof types include flat roofs, sloped roofs, or sheet metal roofing.

- Walls: Partition and exterior walls should meet requirements for durability, insulation, soundproofing, and fire resistance. The drawings specify wall dimensions, structure, and materials.

- Windows: Windows must provide natural lighting and proper ventilation. Their size and position should enhance airflow and light distribution.

- Doors: Factory doors must ensure ease of access and fire safety. Main and auxiliary doors should accommodate goods transport and comply with fire protection standards.

Architectural drawings define the form and structure of the factory, combining aesthetics with technical requirements. A well-designed building reduces maintenance costs and enhances long-term usability, providing a safer and more comfortable environment for workers. It also boosts the overall sustainability and operational efficiency of the factory.

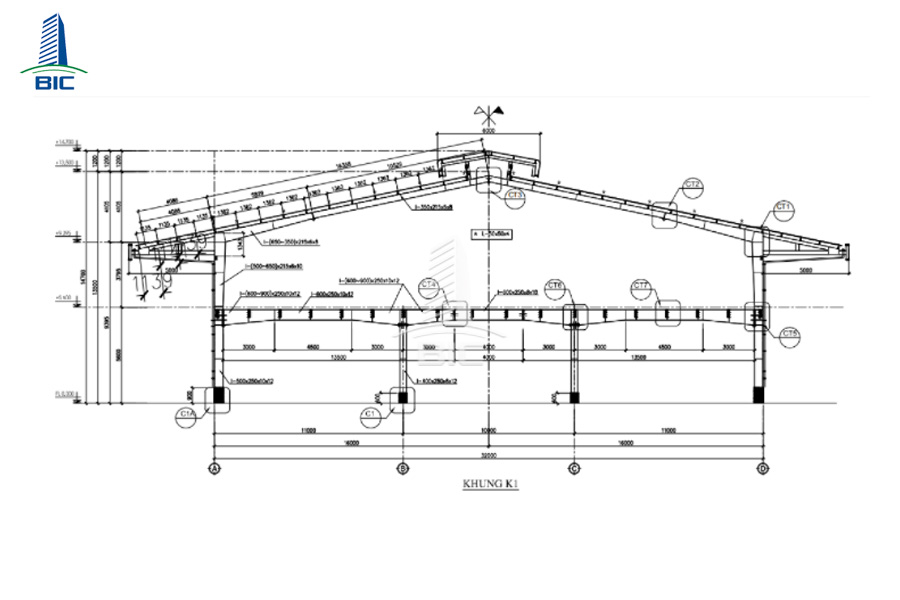

Structural drawings provide detailed information about the load-bearing components of the factory, such as foundations, columns, beams, floors, and other structural elements. These drawings determine the factory’s load capacity, structural integrity, and stability.

- Foundation: The most critical structural element bearing the entire load. Drawings must specify the type (strip, pile, pad, etc.), dimensions, materials, and construction methods.

- Columns: Support vertical loads from the roof and upper floors. Drawings define the type (reinforced concrete, steel, etc.), size, and distribution.

- Beams: Transfer loads from the upper structure to columns. Drawings detail their size, materials, and connection to other components.

- Floors: Surfaces for production and storage activities. Drawings include types (concrete, steel, etc.), thickness, materials, and load capacity.

- Other load-bearing components: Such as braces, steel frames, trusses, cranes, and additional supporting structures.

Structural drawings are vital for ensuring the safety and durability of the factory. A sound structural design can withstand forces such as gravity, wind, and seismic activity, extending the building’s lifespan and minimizing repair costs. Structural designs must be handled by qualified engineers following technical standards and safety regulations.

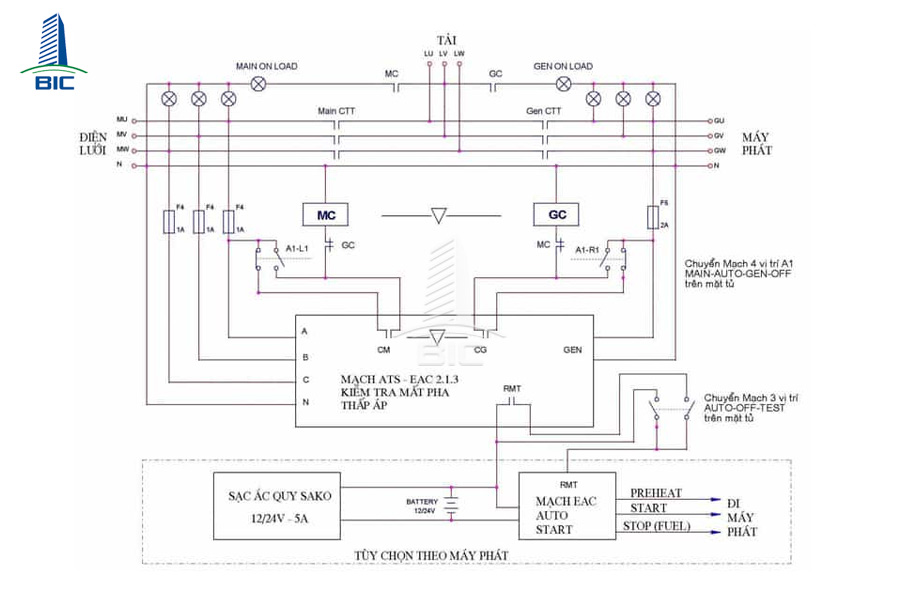

M&E drawings show the design of mechanical and electrical systems within the factory, including power supply, water supply and drainage, ventilation, and air conditioning. These systems are essential for smooth, safe, and efficient factory operations.

- Electrical system: Includes wiring, power panels, lighting, outlets, electrical equipment, overload protection, circuit breakers, and backup power such as generators.

- Water supply and drainage: Covers both domestic and industrial water supply systems, stormwater, and wastewater drainage. Includes piping, tanks, treatment systems, and sanitary fixtures.

- Ventilation: Ensures air circulation and humidity control. Drawings show placement of vents, fans, air ducts, and other ventilation equipment.

- Air conditioning: Maintains suitable temperature and humidity, especially in climate-sensitive production environments. Drawings specify air conditioners, ducts, cooling systems, and temperature control devices.

M&E drawings are critical to the functionality of a factory. Proper M&E design ensures efficient system operation, production continuity, energy savings, and cost optimization. These systems must also comply with safety standards to protect workers and the working environment. A well-designed M&E system minimizes failures, extends equipment lifespan, and enhances overall operational performance.

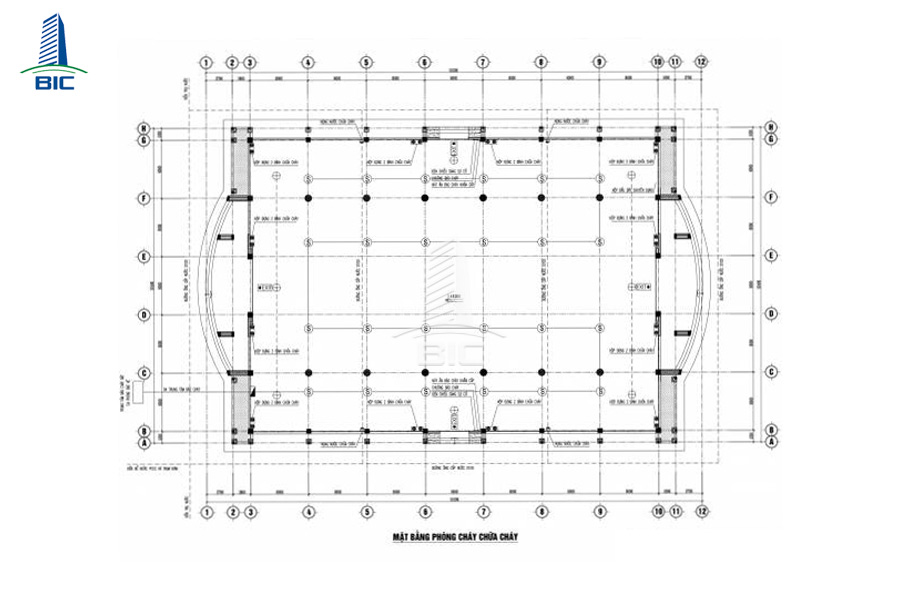

Fire protection drawings are design blueprints for the fire safety system of a factory, including fire-fighting equipment, fire alarm systems, and emergency exits. These drawings are indispensable in factory design to ensure maximum safety for both workers and property against the risk of fire and explosion.

- Fire-fighting equipment: This includes fire extinguishers, sprinklers, fire hydrants, water tanks, and other fire-fighting devices. The drawings must clearly indicate the location, quantity, and type of equipment suitable for each area of the factory.

- Fire alarm systems: These include alarms, warning lights, smoke detectors, and heat sensors. The drawings must show the exact locations of sensors and alarm systems to allow for early fire detection and timely response.

- Emergency exits: These are escape doors, staircases, and passageways designed to ensure that workers can evacuate safely during fire incidents. The drawings must identify all escape routes, ensuring they are unobstructed and sufficient for the number of personnel.

Fire protection drawings are crucial for ensuring the safety of workers and assets in the factory. A well-designed fire protection system that complies with fire safety regulations not only minimizes damage in case of an incident but also helps meet legal requirements. Fire alarm systems, extinguishers, and emergency exits must be logically arranged, easily accessible, and effective in emergencies to safeguard human lives and company assets.

Internal traffic system drawings show the design of the internal transportation network within a factory, including routes for vehicles and pedestrian walkways. This part of the design ensures logical space planning and facilitates the smooth movement of raw materials, products, and personnel throughout the facility.

- Traffic routes: The drawings should clearly depict main and secondary roads within the factory premises, including lanes for trucks, forklifts, and other machinery. These routes should provide easy access to all functional areas to ensure safe and efficient transportation.

- Parking areas: The drawings must define designated parking spaces for employees, visitors, and cargo vehicles. Proper separation and layout are required to prevent congestion and accommodate special vehicles like trucks or containers, if applicable.

Internal traffic system drawings play a vital role in ensuring operational efficiency. A well-planned internal transport layout enables faster, safer movement of workers and vehicles, minimizing downtime. Additionally, logical road and parking design helps maximize space usage, reduce congestion, and improve overall safety on-site.

HVAC drawings illustrate the design of ventilation and air conditioning systems in factory buildings. These systems help regulate temperature, humidity, and air quality, creating a safe and comfortable working environment while supporting production efficiency.

- Ventilation system: Includes ventilation openings, air ducts, exhaust fans, and ventilation units. These elements must be designed to allow for proper air circulation, removing pollutants and introducing fresh air.

- Air conditioning system: Features industrial cooling or heating units, ductwork, indoor and outdoor AC units, and distribution systems tailored to different functional areas. The system must be efficient and energy-saving.

- Air filtration systems: In environments with pollution or dust, air purifiers and central filtration units are necessary. The drawings should specify locations for filters, dust collectors, and purification systems.

- Humidity control system: For factories requiring specific humidity levels (e.g., food or pharmaceutical production), automatic humidifiers or dehumidifiers must be included. Drawings should indicate the types and placement of these devices.

- Controllers and sensors: Centralized control units for monitoring and adjusting temperature, humidity, and airflow. Sensors for temperature, humidity, and air quality should be integrated to maintain optimal working conditions.

HVAC systems are vital to maintaining a healthy and productive working environment. Controlled temperature and humidity enhance employee comfort, reduce fatigue, and improve productivity. A well-designed HVAC system also saves energy and reduces operational costs. HVAC drawings must accurately depict the layout of ducts, fans, filters, and climate control equipment to optimize performance and efficiency.

Sectional drawings are cross-sectional views of the factory that show internal construction details and floor levels. These drawings help engineers and contractors understand how building elements are arranged and interact with one another, especially in terms of structural height, construction components, and usable space.

- Structural details: The drawings must illustrate foundations, columns, beams, walls, roofs, and other load-bearing elements, providing insight into how the structure is built.

- Building height: Information about floor-to-ceiling heights, roof elevations, and vertical spacing to ensure optimal work and operational space.

- Technical systems: Includes electrical, water supply, HVAC, and fire protection systems to ensure integrated and safe building performance.

- Spatial layout: Gives a clear view of how various spaces such as production zones, warehouses, offices, and service areas are distributed and used.

- Inter-floor connections: Shows how different floors or zones interact, including staircases, mezzanines, or skylights, which help in evaluating structural continuity.

- Doors, windows, and emergency exits: These elements must be detailed for effective evacuation planning and daylight/ventilation considerations.

Sectional drawings offer a deeper understanding of the structure, allowing precise evaluation of construction layers, vertical circulation, and service integration. They are critical for accurate material estimation, proper installation of systems, and verifying compliance with ventilation, insulation, and acoustic standards. These drawings also help detect and resolve potential structural issues early in the design or construction phase.

In factory design, drawings play a crucial role in ensuring the functionality, safety, and overall efficiency of the facility. Each type of drawing from the master plan, functional layout, structural drawings, to technical systems such as HVAC and fire protection contributes significantly to creating an optimal, safe, and sustainable working environment. Additionally, elements like internal traffic systems, ventilation, and air conditioning are essential to optimize the operational performance of the factory.

To ensure construction quality, choosing a reputable and experienced design firm is extremely important. A professional design construction team will help you optimize every aspect of the project from space utilization to technical systems ensuring the facility not only meets all standards but also minimizes operating costs. Contact BIC today for expert consultation on factory design, cost optimization, and quality assurance. Let us accompany you in building a productive, safe, and sustainable manufacturing space.